Chapter 6: Molecular Techniques BIO281 Biomanufacturing

advertisement

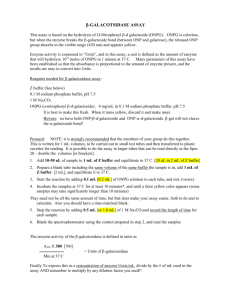

BIO281 Biomanufacturing Techniques Lab BIO281 Biomanufacturing Techniques Lab Enzyme Handling & Assay Protein Assay & Bioreactor Operation Cell Fractionation & Protein Purification Analytical Techniques for Purity & Identity Course Overview This course provides an additional dimension to Biotechnology by introducing the students to product-oriented application of the molecular biology methods they have already studied. The principles learned in this course are relevant to upscaling for a biomanufacturing processes Using the E. coli ATCC 37658 strain with plasmid-borne ß-galactosidase enzyme activity, the class provides instruction and experience in spectrophotometric enzyme assay, growing cells using a BioFlo 110 bioreactor, and in obtaining a purified protein product that is representative of commercial production procedures. The content includes the following topics: Protein structure and properties Guidelines to handling and working with proteins Enzyme induction and control Protein determination and enzymatic assay Large-scale bacterial growth Preparation and operation of a bioreactor vessel Cell fractionation and centrifugation Strategy and methods for protein purification Principles of size exclusion and ion exchange column chromatography Protein gel electrophoresis and staining Western blot and antibody probe techniques Page 8 Advanced Biotechnology Certificate Instructional Laboratory Manual Chapter 6: Molecular Techniques Experimental procedures for the labs for this course are taken from Protein Purification Manual, J. Mowry and L. Seidman, Madison Area Technical College. Specific procedures for induction of ß-galactosidase are from “Experiments in Molecular Genetics”, Jeffrey H. Miller, Cold Spring Harbor Laboratory, 1972. Operation of the bioreactor is found in the “Guide to Operations for the BioFlo 110 Fermentor”, New Brunswick Scientific Manual M1273-0054. Other procedures are available in the Coursework section for each unit. Skills to be developed and assessed can be found in the BIOHUB. Learning Outcomes: The intention is for the student to be able to: 1. Modify single living cells in order to produce desired characteristics. 2. Overcome the challenges of performing successful upscaling techniques: Bioreactor preparation and operation Cell harvesting and fractionation techniques Protein purification methods, including chromatography Enzyme handling and enzyme activity assay methods Protein assay methods Protein gel electrophoresis techniques Western blot/enzyme antibody probe techniques Course Competencies Actions that are essential to achieve the learning outcomes: 1. Perform large-scale bacterial cell growth for a specific biomanufacturing process. 2. Validate the principles and importance of sterility in industrial fermentations 3. Demonstrate aseptic technique and sterility control procedures 4. Complete external measurement of fermentation parameters 5. Demonstrate preparation of seed inoculums 6. Recover protein biomass 7. Calculate the efficiency of a fermentation process 8. Demonstrate preparation of bioreactor media and seed inoculums 9. Operate a plan, execute and validate bioproduct purification procedures 10. Comply with regulatory and ecological guidelines in the operation and design of fermentation processes Page 2