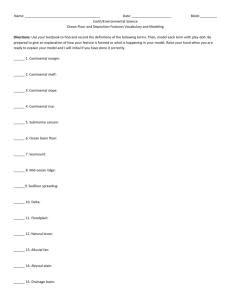

Press Release as Word-Document.

advertisement

-1- Bridge Move on Continental Tires Cuts Construction Time Minnesota Department of Transportation moves bridge sections into place with Self-Propelled Modular Transporter Contractor Mammoet rolls bridge with 352 Continental IC40 industrial tires Bridge closure time cut in half with new technology Fort Mill, South Carolina, October 31, 2012. Long-term construction projects and resulting traffic delays can cause headaches for commuters, but the Minnesota Department of Transportation (MnDOT) recently found a way to cut a bridge replacement project time in half – with a device that uses Continental industrial tires. MnDOT closed and dismantled the Maryland Avenue Bridge spanning I-35E in St. Paul in July as part of interstate corridor improvements planned for 2012 to 2015. A new bridge deck and superstructure were built during the course of the summer on the west side of the roadway. On August 18 crews used a giant, automated self-propelled modular transporter (SPMT) to move the finished sections of the bridge across the highway and set them into place. The transporter was operated by global heavy moving and transport expert Mammoet, whose Illinois-based civil project unit was contracted by MnDOT to oversee the delicate move. The SPMT, a multi-axle platform machine controlled by computer, moved the bridge sections at a walking pace, rolling them on 352 wheels with special Continental industrial tires based on the IC40 Extra Deep design. Each wheel can be swiveled independently to allow the bridge weight to be distributed evenly, according to Mammoet. The bridge move took place during a single day, with both sections in place by 8:30 p.m., according to MnDOT sources. Federal funds dictate the use of accelerated construction technologies, specifically the SPMT, in order to improve work zone safety and reduce traffic disruption. With traditional construction methods the Maryland Bridge would have been closed for nearly four months. Instead, the closure will be reduced to about 60 days. Your contact person: Ute Weiß, telephone: +49 511 938-2131 -2The heavy load carrying capacity and durability of the Continental IC40 industrial pneumatic tires has made them the choice of Mammoet Transport for its SPMTs. Mammoet has also used Continental IC40 tires to move a solid stone church in Germany in 2007; the company achieved a record move of a 15,000 ton oil separation plant at a Norwegian shipyard in 2010 using 2,160 IC40s over 540 axle line SPMTs. The Continental tires are specified for Mammoet SPMTs because they can stand up to not only the weight of the materials transported, but also to the immense forces generated when each wheel is individually steered, according to Mammoet. MnDOT crews have additional work to complete before the bridge opens to traffic in midSeptember, according to the project Website. More information about the I-35E Maryland Avenue Bridge project is available at http://www.dot.state.mn.us/metro/projects/35estpaul/maryland.html. A YouTube video of the bridge move, filmed by MnDOT, is linked on the Continental Industrial Tires channel, www.youtube.com/ContiIndustrialTires. With sales of €30.5 billion in 2011, Continental is among the leading automotive suppliers worldwide. As a supplier of brake systems, systems and components for powertrains and chassis, instrumentation, infotainment solutions, vehicle electronics, tires and technical elastomers, Continental contributes to enhanced driving safety and global climate protection. Continental is also an expert partner in networked automobile communication. Continental currently has approximately 169,000 employees in 46 countries. Further information you will find here: www.continental-industrial- tires.com Picture: Giant automated self-propelled modular transporter Giant, automated self-propelled modular transporter (SPMT) moves sections of the bridge across the highway. Picture: Continental’s IC40 industrial pneumatic tires on SPMTs of Mammoet Continental’s tires are specified for Mammoet SPMTs, because they stand up to the weight of the materials transported, as well as to the immense forces generated when each wheel is individually steered. Your contact person: Ute Weiß, telephone: +49 511 938-2131 -3Contact: Ute Weiß Communications/PR Manager Business Unit Industrial Tires Continental Büttnerstraße 25 30165 Hannover Germany Telephone: +49 (0) 511 938-2131 Fax: +49 (0) 511 938-2706 E-Mail: ute.weiss@conti.de Jackie Pobiega Communications Manager, Commercial Vehicle Tires Continental Tire the Americas, LLC 1830 MacMillan Park Drive Fort Mill, SC 29707 Phone: 704-583-8564 Fax: 704-583-8737 E-mail: jackie.pobiega@conti-na.com Media Center on www.mediacenter.continental-corporation.com Your contact person: Ute Weiß, telephone: +49 511 938-2131