XAD-8 & XAD-4

advertisement

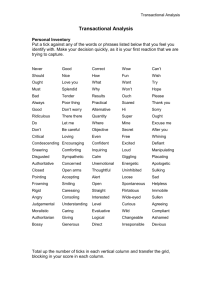

XAD-8 & XAD-4 Experimental Procedure * This procedure is for extracting NOM fractions with XAD-8 resin. The procedure for XAD-4 is generally the same as XAD-8. Differences such as flow rates are noted. Prior Procedures Needed XAD resin cleaning Supplies needed * Based on 6, ~500 ml samples 6 - Spectrum ~50 ml, 1 cm diam. columns 18 - 600 ml glass bottles (thoroughly washed) ~22 - 40 ml glass sample vials for DOC analysis (thoroughly washed) 48 ml XAD-8 resin 36 ml XAD-4 resin 1 glass pipette with large opening for loading the columns. (If pipette does not fit in column, another pipette will be needed for water removal from columns during loading) 2L 0.1 N NaOH (8 g NaOH in 2 L MQ water) 2L 0.1 N H3PO4 (14 ml concentrated H3PO4 in 2 L MQ water) MQ squirt bottle 10 ml graduated cylinder timer Apparatus Red line = 8 ml Blue line = 6 ml Column Pump To Sample Bottle or Waste Feed Sample 02/12/16 1 116103888 Tubing clamp Air Purge Screw Overall Procedure * Based on recommended sample and resin volumes (see “XAD-Background”) 1) Pack column with XAD-8 resin 2) Rinse Column 3) Check DOC 4) Prepare Sample 5) Run Sample 6) Repeat for XAD-4 resin (omit Step 4, below) Notes: Acidified samples do not need to be acidified if using the Sievers DOC machine. Therefore, set the acid flow rate in the Sievers to zero for these samples. H3PO4 was used instead of the original HCl to accommodate for the use of the Sievers DOC machine. The Cl- in HCL causes an oxidant demand and subsequent decrease in oxidant available for the oxidation of the NOM. It is recommended that you use different colored tape to mark the raw, XAD-8 eluent and XAD-4 eluent sample bottles to avoid confusing samples Columns may drain via gravity, so check their status on occasion On top fitting, Do NOT over tighten fitting because the glass may crack. On bottom fitting (shown below), All Fittings should not be adjusted during operation or cleaning. If the valve becomes loose, Do NOT over tighten because the Teflon threads will strip and the valve will need replacement Do Not Loosen for cleaning or Over Tighten Do Not Over Tighten if loose (Thread stripping will occur) When turning the valve on and off, be sure to hold the valve with the other hand to prevent over tightening of the fitting. 02/12/16 2 116103888 XAD-8 Flow rate = 1.3 – 2.0 ml/min. Step 1 – Load Column 1) Ensure valve is turned off to prevent column from running dry. 2) Load column with resin to appropriate volume. Be aware that the resin may settle over time (up to 0.5 ml) 3) Before screwing on top of column, make sure all resin beads are removed from threads and lip of column. (Failure to do so will damage the threads and seal and may cause leaks) Step 2 – MQ rinse 1) Purge air from column and rinse column with MQ overnight (~12 hours) or with at least 500 ml. Step 3 – Acid/Base Rinse Note: When pumps are not running (i.e. when switching rinsing solutions), it is recommended that the column valves be shut off to prevent columns from draining by gravity. (Turn the valve off first and then immediately turn the pump off to prevent a pressure spike) 1) Rinse column with 0.1 N NaOH for ~1-3 hours. At the end, take a sample of the feed NaOH solution and the product. Lower the pH of theses two samples to ~7 with H3PO4 and measure the DOC. The difference between the feed and product should be no more than a few hundred ppb. The NaOH will cause a rise in the DOC of the feed MQ solution to ~500 ppb. While waiting for the DOC to run, complete steps 2 and 3. 2) Rinse column with ~ five column volumes (void volume + head space 4 ml) of MQ (t 25 min.) 1) Rinse with NaOH 2) Rinse with MQ 3) Rinse with H3PO4 To Waste To Waste Collect vial for DOC measurement To Waste 02/12/16 Collect vial for DOC measurement 3 116103888 3) Rinse column with ~ five column volumes of 0.1 N H3PO4, phosphoric acid (t 25 min.) 4) If the differential DOC is too high, repeat the steps, re-measuring the product DOC. 5) Be sure to finish off with steps 2 and 3 before running the sample Step 4 – Sample prep 1) Obtain at least 600 ml of 0.45 m filtered sample Note: If sample is limited, values (i.e. XAD volume) will have to be adjusted 2) Acidify sample to pH = 1.90 – 2.00 with H3PO4, check with pH paper. (If samples have high carbonate levels they will likely require sparging to remove the CO2 gas produced. Sparge for 5-10 minutes with He (g) passed through a glass fritted sparger) 3) Collect sample for raw water DOC and UV analysis Step 5 – Sample run 1) Run sample through column to waste with one column volume + tubing volume to rinse out MQ water (~6 min.). Check flow rate with graduated cylinder and timer. 2) Run sample through column according to previous calculation (see “XAD Background”) 3) Collect column effluent in 600 ml glass bottle for XAD-4 analysis. 4) Remove 2 - 40 ml samples from glass bottle at end of run for DOC and UV analysis. 1) Run 1 column volume of sample To Waste 2&3) Run sample Collect effluent XAD Effluent Clean Up) Rinse Column with MQ Collect effluent To Waste XAD Effluent 8) Collect 2 vials, for DOC and UV measurement 4) Collect 2 vials, for DOC and UV measurement 02/12/16 6&7) Elute off absorbed NOM 4 116103888 Note (Steps 5-8): Back elution is performed to be able to obtain UV measurements materials attached to the resin and/or to perform a mass balance. If this info is not needed, go to clean-up. It is possible to do this in a reverse direction, by reversing the tubing, but this often clogs the top fitting with suspended resin. 5) Pump 0.1 NaOH at the lowest flow possible for ~1 hr (dependent on amount of absorbed organic matter 6) Collect sample and lower the pH to ~2 with H3PO4 7) Remove 2 – 40 ml samples from glass bottle at end of run for DOC and UV analysis Step 6 – Clean-up 1) If DOC sorbed on the resin was not eluted, run 0.1 N NaOH solution through column for 0.51 hour to remove the humic substances. 2) Run MQ through system to clear all of the sample from the tubing. 3) Remove resin from column 4) Redraw lines on column that indicate volume (red, blue, black) 5) Clamp column upside down to dry (column top removed) 6) Organize tubing 7) Replenish used supplies (MQ, acid, base) Photo: General look of cleaned up work space and column 02/12/16 5 116103888 QA/QC: XAD extraction of NOM can have a high variability in results due to the many steps and variables in the process. One cause can be the entrainment of air in the column which creates higher flow rates and decreased retention time. It is recommended that triplicate column tests be performed on 10% of the samples to quantify the variability in results. 02/12/16 6 116103888