“Performance Comparison analysis of an endoreversible

advertisement

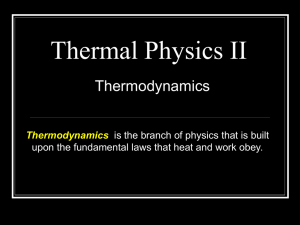

Performance analysis of an endoreversible Heat engine with thermal reservoir of Finite Heat Capacitance at maximum power density conditions GOVIND MAHESHWARI & A.I. KHANDWAWALA Department of Mechanical Engineering, Devi Ahilya University, Institute of Engineering & Technology, Khandwa Road, Indore-452017 INDIA. Abstract : - This paper presents the finite time thermodynamic optimization based on the maximum power density criterion for an endoreversible Carnot heat engine model coupled to variable temperature heat reservoirs. Expressions for the power density and optimal efficiency at maximum power density conditions are derived with heat resistance losses in the hot and cold side heat exchangers. The obtained results are compared with those of using the maximum power criterion. The influences of some design parameters on the maximum power density are provided by numerical examples, and the advantages and disadvantages of maximum power density are analyzed. The power plant design with maximum power density leads to a higher efficiency and smaller size. Key-Words: - Finite time thermodynamics, endoreversible, power density, hot and cold side heat exchangers. at maximum power(MP) conditions. The power density objective was also applied to an ideal reversible Ericsson cycle[5] and an Atkinson cycle[6] free of any irreversibility. Sahin et al[7] applied the MPD technique to the endoreversible Carnot heat engine which can be considered as a theoretical comparison standard for all real heat engines in finite time thermodynamics. In all the above references [3-7], researchers applied MPD techniques to the heat engines having thermal reservoirs of infinite heat capacity. However, for practical applications it is very important to investigate the performance of heat engine when the effect of finite thermal capacitance of thermal reservoirs is taken into account. In this paper we are analyzing the endoreversible Carnot heat engine performance using the power density objective with considerations of the heat transfer irreversibility in the hot and cold side heat exchangers and the effects of finite thermal capacitance rates. The results are compared with those of obtained by using the maximum power criterion. 1 Introduction Since finite time thermodynamics (FTT) or entropy generation minimization was advanced, much work has been carried out for the performance analysis and optimization of finite time processes and finite size devices[1-2]. In these studies, the power output, thermal efficiency, entropy generation and the ecological benefits are chosen for the optimization criteria. However, the performance analyses based on the above optimization criteria do not take the effects of engine sizes related to the investment cost into account. In order to include the effects of engine size in the performance analysis, Sahin et al introduced the maximum power density (MPD) as a new optimization criterion. Using the MPD criterion, they investigated optimal performance conditions for reversible[3] and irreversible[4] non regenerative Joule-Brayton heat engines. In their study, they maximized the power density (the ratio of power to the maximum specific volume in the cycle) and found design parameters at MPD conditions, which led to smaller and more efficient JouleBrayton heat engines than those engines working 1 W Q H Q L H C H TH 1 TW L C L TC TL1 (6) 2 System Description and Analysis A Heat engine working between two thermal reservoirs of finite heat capacitance is shown in Figure 1. The processes 1-2 and 3-4 are reversible adiabatic, and processes 2-3 and 4-1 are isothermal. Assuming that the heat exchangers are counterflow, the heat conductance (product of heat transfer surface area and heat transfer coefficient) of the hot and cold side heat exchangers are UH and UL. The thermal capacity rate (product of mass flow rate and specific heat) of the hot side heat reservoir is CH, and the inlet and outlet temperature of the heating fluid are TH1 and TH2, respectively. The thermal capacity rate of the cold side heat reservoir is CL, and the inlet and outlet temperatures of the cooling fluid are TL1 and TL2, respectively. Temperatures of hot and cold side working fluid of the heat engine are TW and TC respectively. The T-S diagram of the heat engine is shown in Figure 2. The rate of heat flow(QH) from high temperature heat source to the system is given by: QH C H (TH 1 TH 2 ) H C H (TH 1 TW ) The power density defined as the ratio of power produced to the maximum volume in the cycle then takes the form: C T T L C L TC TL1 (7) Wd H H H 1 W V2 The second law requires that: QH QL (8) TW TC H C H TH 1 TW L C L TC TL1 or, (9) TW TC Assuming an ideal gas, the maximum volume in the cycle V2 can be written as mRTC (10) V2 p min where m is the mass of the working fluid and R is the ideal gas constant. In the analysis, the minimum pressure ( p min ) in the cycle is taken to be constant[3]. The power density then becomes p C T TW L C L TC TL1 (11) Wd min H H H 1 TC mR One can maximize the power density given in Eq.(11) with respect to TW and TC by using Eq.(9). The results are: (1) * Tw Similarly, the rate of heat flow(QL) from system to the low temperature heat sink is 1 H L H L 2 CH C L CH C L 2 TH 1 L T L1 H 1 CH T C L1 L 2 CL C H L H 1 H T L1 L 2 CL C H CH C L 2 TL1 T H 1 1 T L1 H CH LCL H CH TH 1 LCLTL1 H 2CH 2TH 1 H CH LCL 3 H CH TH 1 LCLTL1 l 4CL 4TL14TH 1 (12) (2) QL C L (TL 2 TL1 ) L C L (TC TL1 ) where H and L are, respectively, the effectiveness of the hot and cold side heat exchangers, defined as: (3) H 1 exp N H (4) L 1 exp N L The number of heat transfer units, NH and NL are based on the minimum thermal capacitance rates, that is: U U (5) NH H , NL L CH CL The power produced by the engine according to the first law is: TC * 1 L H 2 CL C H TL1 L CL L CL TL1 H CH LCL H CH TH 1 LCLTL1 T C C T H CH TH 1 H 1 H H H H H 1 2 2 L CL 1 L CL 1 L CL 1 1 1 2 H CH TH 1 H CH TL1 H CH TH 1 TL1 TH 1 2 (13) Substituting Eqs. (12) and (13) into Eq(11), the maximum power density (MPD) can be found as * * p min H C H TH 1 TW L C L TC TL1 Wd max * TC mR (14) The thermal efficiency of heat engine is given as: 2 TC (15) TW Using Eqs. (12) and (13) into Eq(15), the efficiency at MPD becomes * TC m pd 1 * TW 1 mpd H L C H C L H 2 C H 2 2 H 2 C H 2 [ L 2 C L 2 H L C H C L H L C H C L H 2 C H 2 ] H C H ( L C L H C H H C H ) (16) TH 1 is the cycle heat reservoir inlet TL1 temperature ratio. Similarly, one can maximize the power output given in Eq.(6) with respect to TW and TC using the condition given in Eq(9). The results are: where Twmp 2 C 2T C C T 2 C 2T T ( C C ) 2 C T H L H L L1 H H H 1 L1 H H L L L L: L1 H H H 1 ( H C H L C L ) H 2 C H 2TH 1TL1 ( H C H L C L ) 2 (17) Tcm p 2 C 2T C C T 2 C 2T T ( C C ) 2 H L H L L1 H H H 1 L1 H H L L L L: L1 ( H C H L C L ) 2 (18) Substituting Eqs(17) and (18) into Eq(6), the maximum power can be found as Wmax H C H [TH 1 Twmp ] L C L [Tcmp TL1 ] (19) The thermal efficiency at maximum power is: mp H L C H C L H 2 C H 2 H 2 C H 2 ( H C H L C L ) 2 H C H ( H C H L C L ) (20) 3 Results and Discussion To see the advantages and disadvantages of maximum power density design, detailed numerical analysis are provided and are compared with those for the maximum power objective. During the variation of any one 3 parameter, all other parameters are assumed to be constant as given below: TH1=1000K , TL1 = 160K, CH = CL = 1 kW/K and H= L = 0.9 . The variations of the normalized power density (Wd/Wdmax) and the normalized power (W/Wmax) with respect to thermal efficiency are shown in Figure 3. As one can see, the thermal efficiency at maximum power density conditions (mpd) is always greater than the thermal efficiency at maximum power conditions (mp). Variations of the two efficiencies (mp and mpd) with and H(=L) are shown in Figures 4 and 5 respectively. The following comments can be summarized from the observations of these figures: (i) For the chosen values of the parameters, the thermal efficiency at MPD(mpd) is greater than the thermal efficiency at MP conditions (mp); (ii)The thermal efficiency advantage of the MPD conditions with respect to MP conditions (= mpd - mp) increases with the increase in (cycle heat reservoir inlet temperature ratio). eg. for = 2, mp = 0.293 and mpd = 0.317, and for = 5, mp = 0.553 and mpd = 0.636. The following observations can also be seen by evaluating Eqs. (16) and (20); (iii)Thermal efficiency at maximum power density conditions increases with an increase in , H and L while thermal efficiency at maximum power conditions increases with an increase of but it is independent of H and L. The variations of the dimensionless power at MPD conditions (Pdmax= Wdmax/(pmin/mR)HCH ) and dimensionless power at MP conditions (Pmax=Wmax/HCHTH1) with are shown in Figure 6. As can be seen from the figure, Pmax is always lower than Pdmax, that is if the design parameters are selected at MPD conditions instead of MP conditions, the thermal efficiency increases as much as by = mpd - mp, and the power increases by P= Pdmax - Pmax. On the other hand, as decreases, mpd and mp, Pdmax and Pmax decreases and get closer to each other and they become zero when = 0. In order to obtain positive performance in terms of thermal efficiency and power for both the MPD and MP conditions, it is necessary that should be greater than zero. The size of a heat engine can be characterized by the maximum volume in the cycle, ie. V2 . The ratio of the maximum volume at MPD to the one at MP can be written as:V max mpd Vmax mp 1 L H L H 2 2 CL CH CL CH 2 1 L H 2 1 L H C L C H C L C H 1 1 1 conditions, engine sizes will be smaller but will require higher maximum pressure than the one operating at MP. 4 Conclusions The performance of an endoreversible Carnot Heat engine cycle coupled to variable temperature heat reservoirs with heat transfer irreversibility in the hot and cold side heat transfer irreversibility in the hot and cold side heat exchangers was analyzed by taking the power density as the optimization objective. Comparisons between maximum power density performance and maximum power performance were made. The maximum power density design has the advantages of smaller size and higher efficiency. All of the analytical results with H = L =1 and CH = CL of this paper replicate the results given by Sahin et al[7] in which Carnot cycle without any irreversibility was examined. The future step of this paper will be the optimization of Carnot heat engine cycle with internal irreversibilities. That will be the subject of another article. L C L H C H L C L H C H L C L H C H H 2 C H 2 H 2 C H 2 2 H CH 1 LC L H C H (21) Similarly, the ratio of the maximum pressures at MPD ((pmax)mpd ) and maximum pressures at MP((pmax)mp) conditions is given by : pmax mpd pmax mp LCL H CH H CH H CH LCL 1 L 2 CL 2 LCL H CH LCL H CH H CH 2 C 2 LCL H CH LCL H CH L L LCL LCL H CH H CH (22) Variations of (Vmax)mpd / (Vmax)mp and (pmax)mpd / (pmax)mp are plotted with respect to in Figure 7. As can be seen from the figures, the ratio of the maximum volumes in the cycle is less than unity and the ratio of the maximum pressures in the cycle is greater than unity. As a result, at MPD 4 Wdmax = Nomenclature CH = Thermal capacity rate of the hot side heat reservoir. (kW/K). CL = Thermal capacity rate of the cold side heat reservoir. (kW/K) Pmax = Dimensionless maximum power output. Pdmax = Dimensionless maximum power density. QH = Heat transfer rate from high temperature reservoir to the system. (kW). QL = Heat transfer rate from cold working fluid to low temp. reservoir. (kW). TC = Temperature of working substance in low temperature reservoir side. (K) TCmp = Temperature of working substance in low temperature reservoir side at max power. (K) * TC = Temperature of working substance in low temperature reservoir side at maximum power density. (K) TH1 = Inlet temperature of the heat source fluid. (K). TL1 = Inlet temperature of the heat sink fluid. (K). TWmp = Temperature of working substance in high temperature reservoir side at maximum power. (K). TW* = Temperature of working substance in high temperature reservoir side at maximum power density . (K). UH = Heat conductance of the hot side heat exchanger. (kW/K). UL = Heat conductance of the cold side heat exchanger. (kW/K). Wmax = Maximum power output from the heat engine. (kW). Wd = Power density of the heat engine. (kW/m3). H = L = = mp = mpd = = Maximum power density of the heat engine. (kW/m3). Effectiveness of source side heat exchanger. Effectiveness of sink side heat exchanger. Thermal efficiency of heat engine. Thermal efficiency of heat engine at maximum power conditions. Thermal efficiency of heat engine at maximum power density conditions. Inlet heat reservoir temperature ratio. References : [1] Curzon FL & Ahlborn B, Efficiency of Carnot engine at maximum power output, American Journal of Physics, Vol.43, No.1, 1975, pp.22-24. [2] Wu C, Power optimization of an endoreversible Brayton gas turbine heat engine, Energy Convers. Mgmt, Vol.31, No.6, 1991, p.561-565. [3] Sahin B, Kodal A & Yavuz H, Efficiency of Joule Brayton engine at maximum power density conditions, J Phy D: App Physics, Vol.28, No.8, 1995, pp.1309-1312. [4] Sahin B, Kodal A & Yavuz H, Maximum power density analysis of an irreversible Joule Brayton Engine, J Phy D: App Physics, Vol.29, No.8, 1996, pp.1162-1171. [5] Erbay LB, Sisman A & Yavuz H, Analysis of Ericsson cycle at maximum power density conditions, ECOS’96 Stockholm, 1996, pp.175178. [6] Chen L, Lin J & Sun F, Efficiency of Atkinson cycle at maximum power density conditions, Energy Convers Mgmt, Vol.9, No.3/4, 1998, pp.337-341. [7] Sahin B & Kodal A, Maximum power density analysis for irreversible combined Carnot cycle, J Phy D: Appl Phys, Vol.22, No.32, 1999, pp.2958-2963 5 Temperature (T) Heat Source TH1 TH2 TH1 TH2 4 Warm working fluid 1 TW QH Heat engine cycle TW TC W 3 Heat Engine Cold working fluid 2 TL2 TL1 TC Entropy (S) Figure 2 : - T-S diagram of an endoreversible heat engine cycle. QL TL2 TL1 Heat Sink Figure 1 : - Schematic diagram of a Carnot heat engine. 6 1.2 W/Wmax Wd/Wdmax W/Wmax, Wd/Wdmax 1.0 0.8 0.6 0.4 0.2 0.0 0.0 0.2 0.4 0.6 0.8 1.0 Figure 3 : - Variations of normalized power density and normalized power with thermal efficiency. 0.7 mpd mp 0.6 mpd, mp 0.5 0.4 0.3 0.2 0.1 0.0 1 2 3 4 5 6 Figure 4 : - Variations of efficiency at maximum power density and efficiency at maximum power conditions with heat reservoir inlet temperature ratio. 7 0.70 mp 0.68 mpd mpd, mp 0.66 0.64 0.62 0.60 0.58 0.2 0.4 0.6 0.8 1.0 H( = L) Figure 5 : - Variations of thermal efficiency at maximum power density and efficiency at maximum power conditions with effectiveness of heat exchangers. Pmax Pdamx Pmax, Pdmax 0.6 0.4 0.2 0.0 1 2 3 4 5 6 Figure 6 : - Variations of dimensionless maximum power and dimensionless maximum power density with heat reservoir temperature ratio. 8 1.00 (pmax)mpd / (pmax)mp 0.98 1.06 0.96 0.94 1.04 0.92 0.90 1.02 0.88 0.86 1.00 1 2 3 4 5 Figure 7 : - Variations of ratio of maximum volume at maximum power density to maximum volume at maximum power conditions and ratio of maximum pressure at maximum power density to maximum pressure at maximum power conditions with heat reservoir inlet temperature ratio 9 (pmax)mpd / (pmax)mp (Vmax)mpd / (Vmax)mp 1.08 (Vmax)mpd / (Vmax)mp