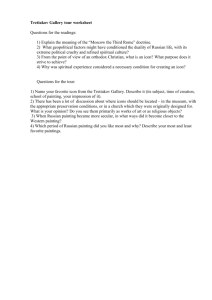

Expiry date: 12 march 2010

advertisement

T.THRISANGU COATING/PAINTING/ INSULATION-INSPECTOR RESUME CARRIER SUMMARY: About 17 years experience in the fields of inspection,Quality control,Engineering study and review. Specialized in protective coatings and Hot/Cold Insulation work in Power,Major oil and Gas Project Construction industries, Cross country pipe line.Out of which 15 years exclusive experience in Habsan-Abudhabi, Karazakanak-Kazakhstan,Sur-Muscat ,Doha-Qatar,Jubail-KSA,kasakhan-kazakhstan Sfax-Tunisia (North Africa), Projects. TWI/B-Gas Certified Painting Inspector level-II Certificate #19325 Expiry date: 12 march 2010 NACE international Certified Painting Inspector CIP Level -1 NACE Certificate Number: 24005 Expiries: 7/31/2012 Work Experience Since October 2009 to till date working as EPC coating/painting/insulation QC Inspector in JGC Saudi Arabia –NPC North Plot Project Jubail. Duties and Responsibilities: Carryout inspection of incoming insulation materials at the job site to make sure that the materials received are as per the approved of client’s specification, necessary certificate and documents are received and complied with the project specification. Check the materials for the appropriate brand, size, thickness, physical condition including packing etc. at the time of delivered to the job site. To ensure complete release of painting, hydro test and heat tracing prior to start of insulation. Conduct inspection and testing at specified stages of installation of insulation and record the results in the inspection report form. Check whether appropriate materials, right size, thickness and quantity in accordance with approved QCP & ITP are applied. Monitoring / surveillance of on going installation of insulation activities. Execute/Perform conductivity test to determine the salt content of the substrate. Conduct final inspection of the installed insulation in accordance with QCP / ITP / Customer drawings and offer the same for client inspection. Prepare the inspection reports in the prescribed inspection report form and obtain client’s approval. Checked thickness, type of insulation, no. of layers required, fit-up and joint arrangement, staggered, tight and unbroken during installation of insulation. Re-inspect the rework or repair if any carried out on the insulation. Inspection of materials for proper storage and handling. Inspection of surface preparation prior to insulation T.THRISANGU COATING/PAINTING/ INSULATION-INSPECTOR RESUME Inspection of proper application of insulation prior to installation of metal jacketing and check metal jacketing for final acceptance. Prepare all application for inspection (AFI) report for final turn over document. To insure all blasting/painting activities are in accordance with project standard /Specification Check surface cleanliness before primer / intermediate and final coat applied. Verify coating system as per Isometric drawing and vendor detailed specs.. Checked paint mixed, agitated, used within specified pot life, correct paint and thinner, etc., and continuously stirred. Verify item, equipment or line is completed, pressure tested and released for painting. Check if works were properly done and coordinate with client representative for final inspection. Verified and inform everyone concerned regarding atmospheric condition prior to blasting/painting works. Carry out wet/dry film thickness of coating and identify coating defect by way of performing detection test. Execute/Perform conductivity test to determine the salt content of the substrate. Verify painting work, painting system and material arrangement. Since January 2009 to August 2009 worked as EPC coating/painting/insulation Supervisor in Petrofac International, Hasdrubal Terminal Project in sfax-Tunisia-North Africa. Duties and Responsibilities: Performing two disciplines as a quality control inspector and supervisor responsible for inspection and supervision of steel structures, painting works& Hot/Cold Insulation. Inspection of protective coatings applied to piping, equipments, spherical tanks, steel structures and instrumentation materials. Assess condition of substrate (grade of cleanliness and amplitude), witness all preparation and preparing documentations. Performing every week to do the adhesion test using dolly test method and salt test. Responsible for supervision of painting and quality assurance/quality control in offsite area. . Since January 2008 to Jan 2009 worked as Agip KCO- Bureau Veritas client coating/painting/insulation QC Inspector in Kasakhan Onshore Experimental project – Karabatan. Atyrau- Kazakhstan. Duties and Responsibilities: Monitoring and evaluation of Contractors Quality job and performance rating to handle a given job. Inspection and evaluation of protective coatings and piping, steel structures and instrumentation materials. Responsible for supervision of painting and quality assurance/quality control in offsite area. Coordination of inspection and work activities between subcontractor and contractor in accordance with approved paint systems and specifications. T.THRISANGU COATING/PAINTING/ INSULATION-INSPECTOR RESUME Responsible for supervision of painting and quality assurance/quality control of utility facilities such as boilers, plant/instrument air, cooling H2O system and chemical injection facilities. Inspecting the fit, wrap, or attach insulating materials to structures of surfaces, using hand tools or wires, following blueprint specifications. Monitoring evenly distribute insulating materials into small spaces within floors, ceilings, or walls, using blower and hose attachments or cement mortar. Monitoring the Cover, seal or finish insulated surfaces or access holes with plastic covers, canvas ships, sealant, tape, cement or asphalt mastic. Inspecting the Prepared surfaces for insulation application by brushing or spreading on adhesives, cement, or asphalt or attaching metal pins to surfaces. Read blueprints and select appropriate insulation, based on the heat retaining or excluding characteristics of the material. Inspecting the Measurement and cut insulation for covering surfaces, using tape measure, handsaw, knife or scissors. Performed manual labor supporting insulation/sheet metal activity, such as cleanup, hauling and stacking materials, and assisting skilled or semi-skilled crafts in the performance of their tasks. This included lifting, carrying and holding materials and cleaning tools, equipment and work areas. Inspection of Fabricated, assembled, installed and maintained various insulation and sheet metal products, such as foam, rigid Inspection of installed foam, blanket or batt on pipes, vessels, valves, machinery or electrical equipment. Inspection of Fabricated or modified prefabricated insulation kits for special purposes, such as valves, pipe fittings, rotating equipment, shaping or forming foam, or cutting and forming sheet metal jackets to conform to specifications. Since June 2007 to December 2007 worked as EPC coating/painting Inspector in Gama/Tekfen JV QC Coating/Painting/Insulation Inspector in Kasakhan onshore Experimental project-Karabatan . Duties and Responsibilities: Responsible for supervision of painting and quality assurance/quality control in offsite area. Responsible for supervision of painting and quality assurance/quality control of utility facilities such as boilers, plant/instrument air, cooling H2O system and chemical injection facilities. Responsible for supervision of painting/quality assurance/quality control in process area (Sulfur recovery unit, LPG Bullet, Amine treating/fuel gas unit. Coordination of inspection and work activities between subcontractor and client in accordance with approved paint systems and specifications. T.THRISANGU COATING/PAINTING/ INSULATION-INSPECTOR RESUME Since Oct 2006 to April 2007 worked as EPC coating/painting Inspector in Saudi Techint Int co., K.S.A. SAUDI-ARAMCO APPROVED COATING INSPECTOR [NORTHEN AREA] Approved SAP #70006901 Duties and Responsibilities: Monitored all coating (2 part epoxy and shrink sleeves) and Holiday testing for FBE conventional lay pipe. Monitored all coating (2 part epoxy and shrink sleeves) and Holiday testing for ARO coated directional drill pipe. Company representative at coating mill to ensure pipe was prepared and coated properly prior to shipping. Performed various utility inspection activities as required; such as, ditching, lowering-in, stringing, clearing right of way, monitoring directional drilling and final clean-up. Project consisted of 25 miles of one 24’ and two 12” X70 pipelines. Having outstanding experience In Cross country Pipeline inspection for different inches and also different Testing for coating and surface preparation. Cross country Pipe line field joints using Heat Shrink Sleeve - Canusa and Raychem, for DSS & CS Pipes and also FBE Powder Coating using Induction Coil method in field joints for different inches. Single coat system for buried lines using hempel and jotun and final inspection for cross country pipelines Since July 2005 to July 2006 Worked as painting/coating inspector in Peninsular Petrotec Engg., Teyseer Group of companies (Qatar) Client: Qatar Steel Company /Qatar Petroleum Duties and Responsibilities: To insure all blasting/painting activities are in accordance with project agreed standard & specification. Checked if works were properly done and coordinate with client representative for final inspection. Verified and inform everyone concerned regarding atmospheric condition prior to blasting/painting works. Carry out wet/dry film thickness of coating and identify coating defect by way of performing detection test. Prepare daily report drafting & check. Execute/Perform conductivity test to determine the salt content of the substrate. Conduct toolbox meeting to workers regarding proper execution of works, housekeeping including safety matters. Prepare daily inspection notification. Verify painting work, painting system and material arrangement. To assist in implementing safety and foremost is to make good representation of the company and or/ liaison with the client. T.THRISANGU COATING/PAINTING/ INSULATION-INSPECTOR RESUME Since July 2004 to April 2005 Worked as painting/insulation inspector in Consolidated Contractor Company Muscat Client: Oman-India fertilizer (Omifco). Duties and Responsibilities: Verify that the correct paint system, procedures & specification has been followed according to the project requirement. Inspection of surface cleanliness based on SIS, ISO /SSPC standards. Monitor / Record daily weather parameters. Performs various test related to QC painting discipline. Prepares inspection request and records including documentation of accepted works. Tests include the following; DFT & WFT measurements, salt test, holiday/spark test air contamination test, oil contamination test for abrasive, adhesion test and others. Color coding application and labeling for piping and equipments. Other activities as instructed by my superior related to painting works; e.g., Line tracing for completed works, check paint systems thru line list and others. Since Jan 2001 to April 2004 Worked as JV painting/insulation inspector in CCC/Saipem (Jv) kazakhstan Client:KPO Bv., Duties and Responsibilities: Ensuring climatic condition is in accordance with the specification and all corrosion activities are carried out in accordance with agreed standard. Arranging for inspection of completed activity after ensuring compliance with agreed standard. To follow-up any repairs/correction suggested during inspection in accordance with agreed procedure. Record of all inspection and test. Calibration of test equipment. Suggesting /initiating corrective owner’s representative and paint representative. Monitoring wet film thickness during painting application. Monitoring the interval of each coat & record keeping. To ensure all equipment being use is in satisfactory condition. Since Oct 1999 to Oct 2000 Worked as painting/insulation inspector in Consolidated Contractor Company Abu-Dhabi Client: Abu-Dhabi National oil co (ADNOC). Since Dec 1997 to July 1999 Worked as QC Inspector Painting, CCIC KSA Saudi Chevron Petrochemical Project Since Aug 1996 to July 1997 Worked as QC Inspector Painting, M/s Mohammed Al Mojil Group KSA Al- Khobar Power/Desalination Plant Since April 1994 to March 1996 Worked as QC Inspector Painting, CCIC, Bechtel/technip Adnoc OGD-1 Project, Abu Dhabi. Since Jun 1992 to March 1994 Worked as Supervisor in Sujay Engineering Co (Bangalore-India) T.THRISANGU COATING/PAINTING/ INSULATION-INSPECTOR RESUME Health, Safety & Environment: Understand local and international legal and HSE regulations Project specific HSE requirements Witness tool box briefing, safety surveillance & safety audit Attend monthly management safety committee meeting Conduct project safety co-ordination committee meeting (Permit to work system) Administration: Delegation and distribution of responsibilities Employee training needs & wellness programs Constant interaction, counseling & team building session OBJECTIVE: Obtain a position that will allow the utilization of my skills tempered by over 15 years of professional experience in Coatings and, ultimately, to become a long term, highly valued employee of a successful organization. Nationality: Indian Date of Birth: 14.07.1964 Education Qualification: Bachelor in Science (Chemistry) PASSPORT DETAILS: Passport # F8914979 Date of issue: 19/07/2006 Date of expiry: 18/07/2016 Software used:MS office,MS Project Codes&Standards used:SSPC,SIS 05 5900,ASTM,AWWA,ISO 9001:2000 and other international code.