for sites - British Glass

advertisement

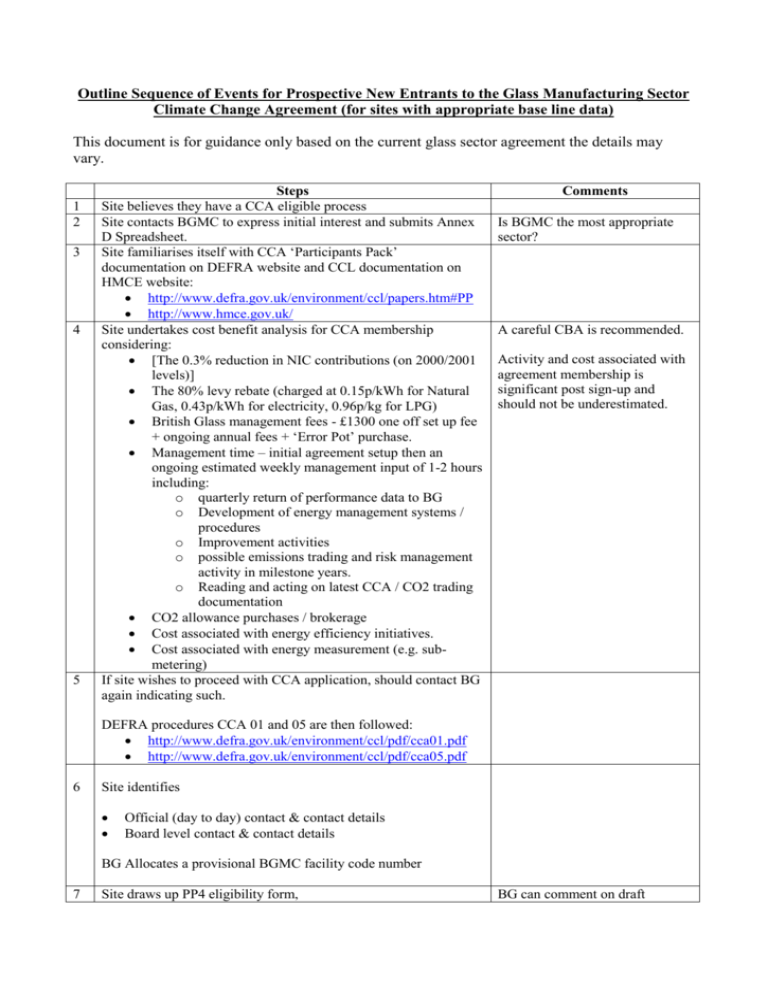

Outline Sequence of Events for Prospective New Entrants to the Glass Manufacturing Sector Climate Change Agreement (for sites with appropriate base line data) This document is for guidance only based on the current glass sector agreement the details may vary. 1 2 3 4 5 Steps Site believes they have a CCA eligible process Site contacts BGMC to express initial interest and submits Annex D Spreadsheet. Site familiarises itself with CCA ‘Participants Pack’ documentation on DEFRA website and CCL documentation on HMCE website: http://www.defra.gov.uk/environment/ccl/papers.htm#PP http://www.hmce.gov.uk/ Site undertakes cost benefit analysis for CCA membership considering: [The 0.3% reduction in NIC contributions (on 2000/2001 levels)] The 80% levy rebate (charged at 0.15p/kWh for Natural Gas, 0.43p/kWh for electricity, 0.96p/kg for LPG) British Glass management fees - £1300 one off set up fee + ongoing annual fees + ‘Error Pot’ purchase. Management time – initial agreement setup then an ongoing estimated weekly management input of 1-2 hours including: o quarterly return of performance data to BG o Development of energy management systems / procedures o Improvement activities o possible emissions trading and risk management activity in milestone years. o Reading and acting on latest CCA / CO2 trading documentation CO2 allowance purchases / brokerage Cost associated with energy efficiency initiatives. Cost associated with energy measurement (e.g. submetering) If site wishes to proceed with CCA application, should contact BG again indicating such. Comments Is BGMC the most appropriate sector? A careful CBA is recommended. Activity and cost associated with agreement membership is significant post sign-up and should not be underestimated. DEFRA procedures CCA 01 and 05 are then followed: http://www.defra.gov.uk/environment/ccl/pdf/cca01.pdf http://www.defra.gov.uk/environment/ccl/pdf/cca05.pdf 6 Site identifies Official (day to day) contact & contact details Board level contact & contact details BG Allocates a provisional BGMC facility code number 7 Site draws up PP4 eligibility form, BG can comment on draft http://www.defra.gov.uk/environment/ccl/download/pp4.doc and submits to DEFRA via BG. 8 completed versions of this form, but ultimate responsibility for accuracy and completeness lies with the site. DEFRA reviews site eligibility and notifies BG: 9 10 Site eligible – proceed to step 9. Site ineligible o review proposed facility definition and resubmit new PP4, or o Withdraw CCA application Site invoiced and pays initial £1300 start up fee to BG Site signs participation agreement between BG and Company Site agrees appropriate throughput measure for facility with BG, and establishes accurate base year energy consumption and production data. When assessing energy use: energy used for external transport fleet is not included. The ‘rules’ for calculating energy use in a facility are given in the glass sector umbrella agreement found at http://www.defra.gov.uk/environment/ccl/pdf/203bgma.p df (pp18-23). Energy use should be calculated using gross CV Electricity is reported in primary energy terms by converting from delivered to primary energy units (the relevant factor is year dependent) Oxygen use: Within the glass sector agreement, oxygen is treated as a fuel and factored to primary energy. BG will advise on exact accounting procedures. 11 12 13 Nominal Glass base year is 1999. Whatever base year is selected, it should remain representative of the plant as it currently stands. I.e. the process should not have undergone radical change from that described in the PP4 i.e. the PP4 description should apply both then and now. Accurate annual data must also be provided for years intervening between base and current year. [Note - the procedure is different for existing sites with no suitable base data, or for green field new entrants (who must commission and independent energy consultants report). Consult paper CCA05 for details]. Site establishes: Annual production forecasts to 2010 Energy consumption forecasts to 2010 Scheduled energy saving measures (by fuel) to 2010 beyond business as usual Scheduled energy consumption increasing factors (by fuel) to 2010 (e.g. installation of an EP). Site decides if it wants an absolute or relative target (in terms of carbon or energy). Site develops and proposes milestone targets Target development should consider the following factors: If an absolute target is chosen, production must not have fallen by greater than 10% from the chosen base year to current production. A fall of greater than 10% would immediately invalidate the targets. A bottom up approach to target development is used in the glass sector (versus an imposed top o o o o o o o It is normal practice for operators to develop targets for ‘intermediate’ non-milestone years, as well as the milestone years themselves. Most glass sector facilities have relative targets of the form MWh / tonne ‘produced’. It is preferred that if possible new entrants adopt a similar form of target. The sector SEC efficiency target across the 10 year agreement is ~10% versus base year. New entrants should endeavour to offer savings of at least 10%, where this is realistically achievable. The effect of variable tonnage output on energy consumption (variable MWh / tonne) should also be taken into account. Cullet – Future cullet availability is not easily predicted with certainty. Operators must therefore decide whether or not to take into account any effect this may have on their energy consumption. Furnace ageing – Furnace ageing obviously plays a major role in determining energy consumption. Operators should therefore build this in to their targets ‘up front’, and be aware of the effect that re-scheduling of furnace re-builds will have on performance in milestone periods. The most up to date available data should be used to make forecasts as accurate as possible. down target). This ensures targets are realistic at a facility level. The responsibility for proposed target development primarily lies with the facility concerned. However, BG holds considerable expertise in energy management and can offer assistance in this process. Proposed targets should therefore be forecast using a combination of: Forecast production (i.e. economies of scale) Planned / timed energy efficiency measures Anticipated energy increasing factors (e.g. abatement installation, furnace degradation). 14 15 16 17 For external auditing purposes (and as for base data), the basis of target development should be carefully filed for future reference and possible audit. Targets proposed to FES (& DEFRA) via BG. FES (& DEFRA) review proposal and feed back to BG, who in turn feed back to the facility concerned: If proposed targets are acceptable proceed to step 16. If proposed targets are queried / unacceptable: o review proposed targets and submit fresh proposal / clarification, or o Withdraw CCA application. BG / Facility draw up and sign off underlying agreements. Agreements submitted to DEFRA for endorsement DEFRA endorse agreements and return to BG BG adds company to routine quarterly CCA billing roster BG adds company to CCA member routine mailing lists Proposal should include the information specified in Annex 1 of Paper CCA05 18 19 DEFRA asks HMCE to add facility to ‘Reduced Rate Certificate’ HMCE adds facility to reduced rate certificate, http://www.hmce.gov.uk/business/othertaxes/ccl/red-ratecerts/brit-glass.pdf 20 To receive reduced rate certificate, company submits supplier certificates and supporting analysis forms (PP11, and PP10) to energy suppliers / HMCE. Detailed guidance on completing and submitting forms PP10 and 11 is found on the HMCE website at: http://www.hmce.gov.uk/forms/notices/ccl13.htm#P444_41149 24 BG draws up and issues to facility ‘base data confirmation sheet’ embodying the facilities: Base year energy and production Targets Production forecasts Company checks, signs off and returns base data confirmation sheet to BG. BG sends copy of key agreement documents + new entrants documentation + Glass CCA quality manual to facility, and secures originals at BG offices (Company billed for ‘Error Pot’ carbon purchase) 25 Company enters routine CCA management 21 22 23 Only once a facility is listed here is it eligible for the reduced rate levy. Only once these certificates have been completed and sent will a facility receive the reduced rate certificate. There is no claw back facility for unclaimed rebate. This is necessary to allow the new facility’s targets to be added to the sector level glass targets. CO2 allowance cost equivalent to 0.5% of base year CO2 emissions. This is a sector risk management mechanism contributed to by all agreement participants.