Mechanical Ventilation

advertisement

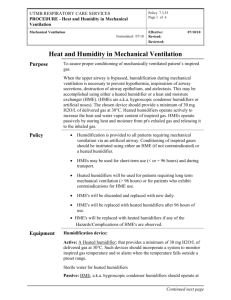

UTMB RESPIRATORY CARE SERVICES PROCEDURE - Heat and Humidity in Mechanical Ventilation Policy 7.3.53 Page 1 of 6 Mechanical Ventilation Effective: Revised: Reviewed: Formulated: 07/10 07/10/10 Heat and Humidity in Mechanical Ventilation Purpose To assure proper conditioning of mechanically ventilated patient’s inspired gas. When the upper airway is bypassed, humidification during mechanical ventilation is necessary to prevent hypothermia, inspissation of airway secretions, destruction of airway epithelium, and atelectasis. This may be accomplished using either a heated humidifier or a heat and moisture exchanger (HME). (HMEs are a.k.a. hygroscopic condenser humidifiers or artificial noses). The chosen device should provide a minimum of 30 mg H2O/L of delivered gas at 30°C. Heated humidifiers operate actively to increase the heat and water vapor content of inspired gas. HMEs operate passively by storing heat and moisture from pt's exhaled gas and releasing it to the inhaled gas. Policy Humidification is provided to all patients requiring mechanical ventilation via an artificial airway. Conditioning of inspired gases should be instituted using either an HME (if not contraindicated) or a heated humidifier. HMEs may be used for short-term use (< or = 48 hours) and during transport. Heated humidifiers will be used for patients requiring long term mechanical ventilation (> 48 hours) or for patients who exhibit contraindications for HME use. HME's will be discarded and replaced every 24 hours. HME's will be replaced with heated humidifiers after 48 hours of use. HME's will be replaced with heated humidifiers if any of the Hazards/Complications of HME's are observed. Equipment Humidification device: Active: A Heated humidifier; that provides a minimum of 30 mg H2O/L of delivered gas at 30°C. Such devices should incorporate a system to monitor inspired gas temperature and to alarm when the temperature falls outside a preset range. Sterile water for heated humidifiers Passive: HME; a.k.a. hygroscopic condenser humidifiers should operate at Continued next page UTMB RESPIRATORY CARE SERVICES PROCEDURE - Heat and Humidity in Mechanical Ventilation Policy 7.3.53 Page 2 of 6 Mechanical Ventilation Effective: Revised: Reviewed: Formulated: 07/10 07/10/10 70% efficiency or better ( Providing at least 30 mg/L Water vapor). Indications Humidification of inspired gas during mechanical ventilation is mandatory when an endotracheal or tracheostomy tube is present. Contraindic ations: There are no contraindications to providing physiologic conditioning of inspired gas during mechanical ventilation. An HME is contraindicated under some circumstances: Use of an HME is contraindicated for patients with thick, copious, or bloody secretions. Use of an HME is contraindicated for patients with an expired tidal volume less than 70% of the delivered tidal volume (e.g. those with large bronchopleurocutaneous fistulas or incompetent or absent endotracheal tube cuffs). Use of an HME is contraindicated for patients with body temperatures less than 32°C. Use of an HME may be contraindicated for patients with high spontaneous minute volumes (> 10L/min). An HME must be removed from the patient circuit during MDI and aerosol neb treatments when the nebulizer is placed in the patient circuit. Procedure Step 1 Action Select a humidification device in accordance with policy. If an HME is chosen: Place the HME in the circuit between the inspiratory and expiratory limb (so both inspired and expired gas passes through it). 2 Attach the circuit to the patient's endotracheal or tracheostomy tube. 3 Inspect HME with patient/ventilator system checks and prn. Replace the HME anytime secretions contaminate the insert or filter. Continued next page UTMB RESPIRATORY CARE SERVICES PROCEDURE - Heat and Humidity in Mechanical Ventilation Policy 7.3.53 Page 3 of 6 Mechanical Ventilation Effective: Revised: Reviewed: Formulated: 07/10 07/10/10 Procedure Continued Step 4 Action If a heated humidifier is chosen: Set up unit in accordance with manufacturer's instructions and place in inspiratory limb of circuit. Hazards/Co mplications: 5 Connect water supply as instructed by manufacturer. 6 Place temperature probe to monitor temperature as near the patient's airway opening as possible 7 Turn heater unit on and set temperature to maintain inspired gas at 33 ± 2°C. 8 Set high temperature alarm no higher than 37°C, and the low temperature alarm no lower than 30°C. 9 Check the humidification device as well as inspired gas temperature, water level and function of automatic feed system (if applicable) during the patient-ventilator system checks and prn. 10 If using heated wire circuit adjust wire heat to maintain some condensate in the inspiratory limb of the circuit. Remove excess condensate from the patient circuit as necessary. Both HME's and heated humidifiers. Hypothermia--HME or heated humidifiers. Underhydration and impaction of mucus secretions--HME or heated humidifiers. Hypoventilation and/or alveolar gas trapping due to mucus plugging of airways--HME or heated humidifier. Possible increased resistive work of breathing due to mucus plugging of airways--HME or heated humidifiers. Possible increased resistive work of breathing through the humidifier--HME or heated humidifiers. Continued next page UTMB RESPIRATORY CARE SERVICES PROCEDURE - Heat and Humidity in Mechanical Ventilation Policy 7.3.53 Page 4 of 6 Mechanical Ventilation Effective: Revised: Reviewed: Formulated: 07/10 07/10/10 HME's only: Possible hypoventilation due to increased dead space--HME. Ineffective low-pressure alarm during disconnection due to resistance through HME. Heated humidifiers only: Inadvertent overfilling resulting in unintentional tracheal lavage-heated reservoir humidifiers. Some ventilators generate a high flow through the patient circuit that may aerosolize contaminated condensate, putting both the patient and clinician at risk for nosocomial infection--heated humidifiers. Elevated airway pressures or inadvertent tracheal lavage from pooled condensate in patient circuit--heated humidifiers. Patient-ventilator dysynchrony and improper ventilator performance due to pooled condensation in the circuit--heated humidifiers. Hyperthermia or thermal injury to the airway from heated humidifiers; burns to the patient and tubing meltdown if heated-wire circuits are covered or circuits and humidifiers are incompatible. Potential for electrical shock or burns --heated humidifiers. Frequency: All patients with an artificial airway requiring mechanical ventilation should receive continuous humidification of inspired gases. Infection Control Follow procedures outlined in Healthcare Epidemiology Policies and Procedures #2.24; Respiratory Care Services.http://www.utmb.edu/policy/hcepidem/search/02-24.pdf Note: In general, with heated humidifiers sterile water should be used When using a closed, automatic feed system, the unused portion of water in the water feed reservoir remains sterile and need not be discarded when the patient circuit is changed. However, the water feed system should be designated for single patient use only. Because condensate is potentially infectious waste, it should never be drained back into the humidifier reservoir. (somewhat controversial gas flow through certain reservoirs can produce aerosol, others may not). Continued next page UTMB RESPIRATORY CARE SERVICES PROCEDURE - Heat and Humidity in Mechanical Ventilation Policy 7.3.53 Page 5 of 6 Mechanical Ventilation Effective: Revised: Reviewed: Formulated: 07/10 Source/Refe rences: 07/10/10 AARC Clinical Practice Guideline - Humidification during Mechanical Ventilation. Respir Care 1992;37:887-890 . Continued next page UTMB RESPIRATORY CARE SERVICES PROCEDURE - Heat and Humidity in Mechanical Ventilation Policy 7.3.53 Page 6 of 6 Mechanical Ventilation Effective: Revised: Reviewed: Formulated: 07/10 Safety 07/10/10 All alarms on ventilators will be activated at all times. Anesthesia gases will not be administered through ventilator. Correspond- Respiratory Care Services Policy # 7.4.11; Operating Instructions For Adult Microprocessor Controlled Ventilators ing Policies References AARC Clinical Practice Guidelines; Patient-Ventilator System Checks, Respiratory Care; 1992; 37: 882-886 AARC Clinical Practice Guidelines; Humidification During Mechanical Ventilation, Respiratory Care; 1992; 37: 887-890 Donald F. Egan, Craig L. Scanlan, Robert L. Wilkins, James K. Stoller, Egan's Fundamentals of Respiratory Care, Eighth Edition, Mosby; June 2, 2003 Dean Hess, Robert Kacmarek, Essentials of Mechanical Ventilation, McGraw-Hill Professional; 1st edition (March 1, 1996) Ventilator Operating Manuals