VILLIN MODEL CONSTRUCTION

advertisement

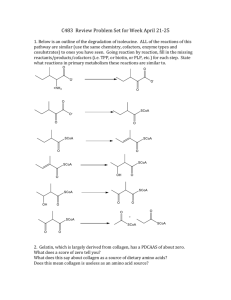

VILLIN MODEL CONSTRUCTION INTRODUCTION: The construction of this model could have been made out of two types of media. Wood was considered, but rejected, due to its fragile nature. Metal as a construction media will make the model stronger, but will make construction complex. Early on it was decided to allow one aluminum sphere to represent an amino acid. Titanium-steel alloy tubing would connect the spheres. This alloy is not extremely expensive and yet provides a durable and light type of connector. The metal model will be light and have the required strength. ROAD MAP: The villin model consists of 14 different amino acids, that is 36 amino acids long. By protein standards this is a short amino acid sequence. The three dimensional coordinates were available from Dr. Pandee. Using trigonometry, these coordinates were changed into two critical angles ( θ, ψ ) and a length ( r ), which represented the bond length. θ = tan –1 ( y / x ) Page 1 ψ = tan –1 ( z / ( x2 + y2 ) –1/2 ) r = ( x2 + y2 + z2 ) –1/2 Gary Benz The protein was visualized from six different perspectives. The CHIME program was used for this purpose. The protein was pictured from the two ends of the three axes, x, y, and z. The copies were made with each amino acid color coded and the model form used a backbone visualization mode. These pictures were made, because construction of the aluminum spheres holes were not very accurate and some problems did occur during assembly. The exact bond length and angle could be determined, nevertheless guarantying these dimensions was not generally possible. These visualizations kept the model accurate. Any gross errors that began to creep into the model could be fixed using the visualizations. CONSTRUCTION OF PARTS: Each amino acid is composed of two different parts. The alloy tubing was cut to a specified length ( r ) using a metal saw. Each cut was sanded to provide a good fit. Each one inch diameter aluminum sphere had two holes drilled into them. Two marks were made on each sphere. The angle in between the dots was based on the angle ψ. The visualizations are important, because here is where the greatest error occurs. The hole angle is only accurate to ± 3o. Each hole was drilled to a depth of 1 3 inch and a diameter slightly less than 16 inch. The holes are again drilled with a 4 3 16 inch reamer. The use of a reamer makes a tight fit between the sphere and the alloy tubing. Duplicates of each sphere are made, because I quickly realized that the use of a reamer in novice hands, does not guarantee a tight fit. This drilling was monotonomous and was also a source of error. 35 pre-cut pieces of alloy tubing and 72 drilled aluminum spheres were cleaned first soap and water. Grease and oil were removed by soaking the materials in a bath of acetone and then they were allowed to dry. One or two drops of loctite glue were placed inside one of the metal holes of a sphere. The alloy tubing was then twisted into the aluminum sphere. Half of the time the tubing did not have a tight fit. When this occurred the duplicate sphere was used. If neither worked well, the connection was made by hammering the sphere into the alloy connector. The aluminum sphere must be protected from the hammer by using a small cloth towel. The glue was allowed to dry for 24 hours. Finally, each amino acid was color coded and painted. The alloy tube end was taped with a quarter inch piece of scotch tape. This kept the end from being painted. In order for the loctite glue to bond the amino acid pieces together, the reciprocating pieces must be clean metal surfaces. Page 2 Gary Benz 1. Phe BLUE 2. Leu RED 3. 5. 7. Gly Glu Lys GOLD ORANGE GREEN 4. 6. Lys Lys GREEN GREEN 8. 10. 12. 14. 16. 18. 20. 22. 24. 26. 28. 30. 32. 34. 36. Leu Gln Lys Leu Leu Ala Ala Arg Met Phe Ala Phe Glu Ser Met RED ORANGE GREEN RED RED GREY GREY DK. GREEN YELLOW BLUE GREY BLUE ORANGE BLACK YELLOW 9. 11. 13. 15. 17. 19. 21. 23. 25. 27. 29. 31. 33. 35. Asn Gln Trp Pro Asn Phe Ser Thr Gly Val Lys Asp Asp Leu PURPLE ORANGE LT. ORANGE PINK PURPLE BLUE BLACK BRICK RED GOLD RED GREEN WHITE WHITE RED The model is intended to show how the tertiary structure of villin is critical to its function. Other than making the villin model, two hinges will replace the peptide bond between amino acids. One hinge will occur between amino acids two and three, while the other will occur between amino acids seven and eight. The hinges also need to be made of aluminum. This unfortunately introduced a degree of complexity that could only be addressed by an engineer with metal construction experience. The hinges would have to be constructed by an engineer. Free rotation around the peptide bond would be more realistic, but would cause two problems. First, the model would collide with other parts of the villin model during rotation. Second, free rotation would introduce a spectrum of possible structures. Keep in mind only one structure will allow the villin model to function properly. Instead it was decided that two magnets placed inside two aluminum discs would eliminate both of these problems. By placing the magnets 90o apart from each other, only two possibilities would exist. By having two hinges ( the discs sandwiched together ) only four possible structures exist. The diagrams of the hinges are attached as an appendix. ASSEMBLY: Assembly will occur in three phases. The villin model will constructed. It will be made such that it consists of three pieces. Once the pieces are made they will be connected using the hinges. The final model will be fitted with magnets that will bind to a constructed receptor site. Page 3 Gary Benz The villin model is constructed of in three pieces. The first piece consists of amino acids 1 – 2. The second piece is amino acids 3 –7. The final piece is amino acids 8 – 36. The larger piece presented several problems. The final position that individual amino acid should take had to be marked off with a large brick. This was needed because the glue began to dry quickly in the loctite position. The twisting motion needed to put the amino acids together was a coarse motion, but it had to stop at predetermined angle. The large brick was set up so I would stop twisting when the amino acid reached the brick, which represented the correct angle. When the amino acid sequence becomes longer it had to be clamped down so it would not move during the twisting action. Often the pieces would not loctite together and this required the use of a hammer to pound the alloy tube into the reciprocating aluminum sphere. Even when the sequence was clamped down, hammering sometimes lead to the sequence breaking at a weak point along the sequence. The third piece required a considerable amount of patience. The loctite glue must dry for 24 hours. I found that only one amino acid could be added to the sequence each day. This made the assembly a slow process that took an entire month. The model is connected by replacing the alloy tube with the hinges. This was the cause of the model not being finished by the end of November 2003. The hinge did not have the right magnet strength, despite trying to shield the magnet or moving it deeper into the individual discs of the hinge. These hinges are designed to be attached by connecting to two small alloy tubing originating from each adjacent amino acid. Each disc of the hinge has a hole drilled into it to receive the alloy tubing. The mass of these hinges may require some type of model support in between amino acids 9 and 10. The villin model can then be placed in the one out of four “correct” positions. The receptor site for the villin model is represented by a movable dowel, which will have magnets mounted on them. One magnet is place on either amino acid 1 or 2. Another is placed on one amino acid in the sequence 3 – 7, and finally a magnet is placed on either amino acid 8 or 9. The magnets should be placed so that if connected with imaginary segments, the resulting line would be as vertical as possible. The receptor site will have three magnets placed on it so it will bind to the magnets on the villin model will bind to it. Page 4 Gary Benz