2.1.7F Zone Controller, Air Handling Units

advertisement

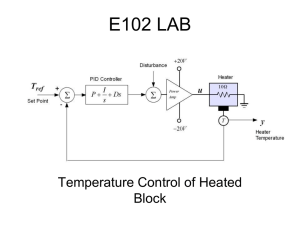

Building Control (Field Installed) Application Specific Controllers / Air Handler Units Air Handler Units — Air Manager Guide Specifications (Controls) 2.1.7 Air Handler Retrofit Controller (ARC) 2.1.7.1 General - Device Description: The Air Handler Retrofit Controller (ARC) shall be a solid state microprocessor based controller used to control each function of the applicable HVAC equipment using Direct Digital Control (DDC) and specifically designed software. The ARC shall be capable of providing stand-alone operation. All application software actually performing the required control functions shall be supplied with the ARC, pre-tested and preconfigured. The ARC shall accept analog and digital signals from sensors, switches, relays, etc., and shall multiplex the various signals into digital format. All closed loop DDC routines shall utilize ARC based software algorithms that shall be resident in the ARC memory. The ARC shall be shipped in a NEMA rated enclosure for mounting where shown on the plans. An on/off switch shall be field installed and wired next to each control panel. The factory shall mount all panel mounted electrical components inside the factory provided control panel. Control transformers for the controlled devices shall be factory supplied and wired. The VAV high limit, Air flow switch, Low Temperature Detector relay, etc., shall be factory installed, piped to bulkhead fittings (when applicable) and pre-wired or as detailed later within this specification. The ARC shall include and maintain an internal time clock function and shall receive time scheduling information from a network occupancy schedule, Linkage Thermostat time schedule, and shall also be capable of interfacing to a dry contact to perform occupancy override. Timed override requests shall be performed by each ARC without any network requirement. The ARC shall not require a battery. All configuration data is to be stored in non-volatile memory. Systems that require a battery to store data are not acceptable. Alarm/Alert Processing — The ARC shall contain a routine to process alarms and alerts. Alarm/alert processing shall consist of a scan of all input points. Certain analog alarms/alerts shall only be monitored when the ARC is in the occupied mode (i.e., static pressure, CO2, relative humidity). Time delays shall be provided with the software to prevent nuisance alarms/alerts during a transition period or if a setpoint change occurs. The controller shall also be capable of providing local alarm/alert indication for out of limit conditions, status, thermistor or sensor failure. All alarms/alerts shall be displayed at a portable PC and via the network to a remote EMS operator’s station or alarm printer, as applicable. When the ARC services VAV terminals, it shall include dynamic interaction linkage software to provide a totally coordinated system, as defined in section 2.1.7 (Terminal Linkage) of this specification. 2.1.7.2 VAV and CV Standard Control Hardware A. The ARC shall include the following standard control hardware for both VAV and CV applications: 1. Supply Air Sensor: The factory supplied sensor shall be a thermistor type, and shall be field installed (RTDs shall also be acceptable). The sensor shall be properly installed to sense the air supply, and field wired back to the ARC. 2. Outside Air Sensor: The sensor shall be a thermistor type, factory supplied for each air handler for field mounting and wiring (RTDs shall also be acceptable). The sensor shall be installed upstream from the outside air damper where it shall accurately sense the temperature of the outside air entering mixing box. Each air handler shall include its own outside air sensor unless all units are being served by a common outside air pleneum. 3. Return Air Sensor (VAV only): The sensor shall be a factory supplied 6 inch probe as a minimum. The sensor shall be a thermistor type, encased in a stainless steel probe to resist corrosion, supplied for each air handler for field mounting and wiring (RTDs shall also be acceptable). 4. Space Temperature Sensor (CV only): The sensor shall be factory supplied for field installation as shown on the plans. The sensor shall consist of a thermistor, terminal block with screw terminals mounted on a printed circuit board, push button for remote occupant override, and a remote communication port (RJ11) (RTDs shall also be acceptable). Space sensors shall include a space temperature adjustment slide for occupant adjustment. The range of adjustment shall be configurable from 0 – 20°F and may be disabled. The sensor shall be mounted approximately 60 inches from the floor and shall be capable of mounting directly to a wall or to a wall mounted standard American electrical box. 5. Fan Relay: The relay shall be factory installed and wired in the control box. The relay shall be a SPDT type and shall interface to the fan motor starter circuit through field wiring to the starter. 6. Two Speed Fan Relays (CV only): Each fan speed relay shall be factory installed and wired in the control box. Each shall consist of a SPDT contact set. Interfaced to the motor starter, the relay shall automatically select the required fan speed for proper operation. 7. Fan Status Switch (CV only): The switch shall be factory installed and wired in the control box. The switch shall be an SPDT snap-acting switch with an operating range of 0.05 to 2.0 in. wg. and a maximum working pressure of 10 in. wg. The Air Flow Switch probe shall be factory supplied and field mounted at the fan discharge, and field piped to the factory installed and piped bulkhead fitting, located at the control panel. 8. Alarm Output Relay: The factory supplied and mounted alarm relay shall be an SPDT type pre-mounted within the ARC control enclosure. Field wiring shall be required from the alarm contacts to the alarming device. Male Quick Connect Terminals shall be provided to facilitate field wiring. 2.1.7.3 Variable Air Volume (VAV): A. The ARC shall include the following hardware for each Variable Air Volume central station in addition to the above: 1. Static Pressure Transducer: The static pressure transducer shall be factory supplied for field installation. The transducer shall have a range of 0 – 5 in. wg. and shall have an accuracy of ± 2% of the range, including non-linearity and hysteresis. The static pressure probe shall be field installed approximately 2/3 down the supply air duct or where shown on the plans. A factory installed bulkhead fitting at the control panel shall be field piped to the pressure probe. 2. Duct High Pressure Switch: The duct high pressure switch shall utilize the common static pressure tube, field piped to a factory provided bulkhead fitting located at the control panel. The high-pressure switch shall be factory installed and wired to the motor starter circuit. The switch shall be SPDT and shall include a manual reset button. The switch shall be factory set at 3.0 in. wg. (adjustable). 2.1.7.4 Variable and Constant Volume Control Options: A. The following control hardware shall be provided for each central air handler device if the control hardware or associated control function is listed in the I/O summary and/or the sequence of operation: 1. Mixed Air Temperature Sensor: The factory supplied sensor shall consist of multiple thermistor sensors evenly spaced and encased in a flexible copper tube. The sensor shall provide both mechanical and electrical averaging to achieve the average temperature measurement over the entire element length. The sensor shall be field installed in the Mixing Box on the upstream side of the filters and shall be serpentined to sense the average temperature. The sensor shall be a minimum of 24 feet. 2. Low Temperature Detector: The Low Temperature Detector (LTD) thermostat shall include a 20 foot long, field installed, capillary strung out in the air stream to protect the coil. Multiple LTDs shall be supplied if required. Field wiring is required between the LTD(s) and the control box. Dry contacts shall be factory wired to the control circuit to stop the supply fan. The LTD status shall be used by the ARC for alarm monitoring. The LTD shall be manually reset at the control panel. 3. Enthalpy Switch: The enthalpy switch shall be factory supplied and field mounted with its sensing element exposed to freely circulating outside air. The sensor shall include an adjustable setpoint. 4. Differential Enthalpy: A factory supplied, field installed differential enthalpy controller shall include two enthalpy sensors; one for the outdoor air and one for the return air. Field wiring shall be required from the ACR to the enthalpy controller. 5. Outdoor/Return/Space Relative Humidity Sensors: The humidity sensors shall be factory supplied and field mounted and wired. The sensors shall use bulk polymer resistance technology to eliminate the effects of surface contamination. The wall mounted RH sensor shall be enclosed within a decorative case. The sensors shall have a measuring range of 10 – 90% with an accuracy of ± 3% at 25°C. 6. Filter Maintenance Switch: The filter maintenance switches shall be field installed in the filter section of the unit. The filter switches shall measure the differential pressure across each filter (as applicable). The switches shall have an adjustable setpoint range of .05 to 2.0 in. wg. The ARC shall be capable of monitoring more than one filter bank, each bank with its own filter maintenance switch. All filter switches (as applicable) shall be field wired to the control panel. 7. CO2 Sensor: CO2 sensors shall be factory supplied wall or duct mounted for field mounting and wiring as shown on the plans. The sensor shall have a maximum range of 0 – 2000 ppm and shall utilize an infrared diffusion sampling cell to eliminate pumps and dust filters. The sensor shall not require calibration or a span gas check. The sensor shall be capable of producing a proportional 0 – 10 VDC control signal and shall include indicating LEDs. 8. Linkage Thermostat (CV only): The factory shall provide one Linkage Thermostat, as required, to provide scheduling and setpoint display and adjustment and to provide system display information at a local level. The linkage thermostat shall provide a minimum of four different levels of password protection. Information exchange between the Linkage Thermostat and the system shall include such dynamic information as; occupied/unoccupied heating and cooling setpoint, zone temperature, bias times for optimization routines, air handler mode and supply temperature, etc. The Linkage Thermostat shall also include an onboard LCD display and adjustment buttons for making changes to schedules, etc., if allowed by password. A separate LCD shall also be provided on the front of the linkage thermostat and shall continuously display the time. The linkage thermostat shall be capable of providing temperature readouts within .1°F and shall include an on board LCD display. Separate adjustment buttons shall be included to allow the operator to make changes. The linkage thermostat shall include a 365-day time clock with built in daylight savings and leap year adjustment. 2.1.7.5 Actuators: A. Valve Actuators: The valves and valve actuators shall be shipped from the factory with spring return capability unless the valve services a non-critical application. The actuators shall use reversible hydraulic or electric motors. Each actuator (heating and cooling) shall be independently powered by a dedicated fused transformer located in the ARC control box. Each actuator shall be capable of interfacing to a modulating output control signal and shall include the capability to hold its position anywhere in its stroke. The valve actuators shall be factory mounted with the appropriate linkage connection on the selected valve assembly for field installation. B. Inlet Guide Vane Actuator (Delete in its entirety if not required): The IGV actuator shall be factory supplied for field mounting and wiring. The actuator shall include a reversible electric motor equipped with a solid-state electric drive. The actuator shall be capable of holding any position at any point within the stroke and moving the IGV in either direction. The actuator shall be capable of interfacing to a modulating output control signal. The actuator shall be individually powered by a dedicated, fused 24VAC transformer located in the control box. C. Damper Actuators: The damper actuators shall be factory supplied and field installed. The actuators shall include an electronically controlled reversible motor equipped with a microprocessor drive. The drive shall provide a constant speed, regardless of load. Actuators shall be capable of holding their position at any point in the stroke in either direction. Each actuator shall be capable of interfacing to a modulating output control signal. The manufacturer shall guarantee to meet the torque requirements of the dampers. Two position minimum outdoor air damper actuators shall be field supplied with a fieldpowered actuator guaranteed to interface to the factory-provided output relay. All wiring shall be field installed. 2.1.7.6 Dampers: * Note: If proposing new dampers then insert the specifications here, otherwise delete. 2.1.7.7 Valves: * Note: If proposing new valves from the factory then use below specification, otherwise delete. All new control valves shall be supplied by the manufacturer. All valves shall be sized by the building control contractor and shall be guaranteed to be of sufficient size and to meet the capacities shown. Two-way and Three-way Valves shall be equal percentage type with a brass body, seat and plug, stainless steel stem, composition disc and spring loaded Teflon coated V-ring packing. The valve body shall be brass, globe, screwed (FNPT) type and shall be rated at 40 – 281°F at 250 psig. 2.1.7.8 Control Algorithms: A. Fan Control: The supply fan shall be started and stopped based on an occupancy schedule, Unoccupied Free Cooling, smoke control (when applicable), unoccupied heating or cooling, demand limiting, network command, and timed override. (Starting and stopping of motor for demand limiting shall pertain to CV units only when tied into a network.) The start of an occupied period shall be determined by either the occupancy schedule, remote timed override, the temperature compensated start routine, or if the remote start contact opens (see I/O summary and/or sequence of operation for requirements). If temperature compensated start is not selected, the supply fan shall start at the occupied time entered in the occupancy schedule. If temperature compensated start is selected, the fan shall be started at the calculated start time. The fan shall stop at the unoccupied time entered in the occupancy schedule. Timed override shall also be used to extend the occupied schedule for up to four hours). Timed override shall be initiated by the operator or by an occupant pushing the override button on the space sensor, if enabled by the operator. During unoccupied periods, whenever the return air temperature falls below the unoccupied heating setpoint or rises above the unoccupied cooling setpoint, the supply fan shall run until the space temperature has returned to the required unoccupied space temperature limits. The supply fan shall also run during the unoccupied period when the unit is in the Unoccupied Free Cooling mode to pre-cool the space prior to occupancy. Whenever the control determines that the fan is no longer required to operate, such as when transitioning into or operating during an unoccupied period, the control shall determine if the previous operating mode provided mechanical cooling, then continue to operate the fan for a period of time in order to evaporate the condensate from the cooling coil fins and reduce the supply duct humidity level. B. Unoccupied Free Cooling (UFC): The ARC shall start the supply fan during cool unoccupied periods to precool the structure mass by using only outside air for units with mixing dampers. Once the space has been sufficiently cooled during this cycle the supply fan shall stop. UFC shall not operate if the outside air temperature is below a user selectable value or if the algorithm determines that the enthalpy of the outside air is unsuitable. C. Temperature Compensated Start: The ARC shall include the software capabilities necessary to detain the morning start-up of applicable HVAC systems until the last possible moment and still allow the building space to reach occupant comfort levels according to the selected occupied time and setpoint schedules for that particular space. A Linkage Thermostat shall be included for each CV air handler, as shown on the plans, and/or sequence of operation, to provide this enhanced system operation. The program shall utilize the thermal characteristics of the space and equipment along with the actual space temperature, outside air temperature, and applicable setpoints. D. Heating Coil Control: 1. CV: The heating coil routine shall modulate the heating valve to maintain the conditioned space’s heating setpoint. The heating coil routine shall also modulate the heating coil valve when the fan is off to maintain a minimum duct temperature to help protect against freezing. The dual loop PID control algorithm shall utilize the space temperature sensor as the master sensor and the discharge sensor as the submaster sensor. 2. VAV: The heating coil routine shall modulate the heating valve for morning warm-up and occupied/unoccupied heating. When the system is indexed to morning warm-up the controlvalve shall open. The dual loop PID control algorithm shall utilize the return air sensor (or average space temperature for systems with terminal linkage software) as the master sensor and the discharge air sensor as the submaster sensor. Once morning warmup is complete, the heating valve shall close and shall not be allowed to open again unless occupied heating has been selected, or if the indoor air quality control algorithms attempts to cause the supply air temperature to fall below the desired supply air temperature setpoint at which point this algorithm shall modulate the valve to keep the supply air temperature at its setpoint. For those systems that require a dehumidification cycle (see I/O summary and/or sequence of operation), the valve shall be modulated to maintain its supply air temperature setpoint when providing a dehumidification cycle, if the heating coil is in the reheat position. E. Electric Heater Control: 1. CV: If the fan is on, the control shall read the space temperature and calculate the required supply air temperature to satisfy conditions. Once the required supply air temperature has been calculated, it shall be compared to the actual supply air temperature to determine the number of heat stages required to satisfy conditions. The electric heat control shall also provide for unoccupied heating whenever the space temperature drops below the heating unoccupied setpoint. If more than one stage is required, the stages shall be enabled one at a time with a time delay between stages. 2. VAV: Electric Heater Control The electric heater routine shall be used primarily for Morning Warm-up or occupied and unoccupied heating. When the supply fan is on the ACR shall determine, based on the return temperature, if heating is required. If it is, the ACR compares the return air temperature to the occupied heating setpoint or unoccupied heating setpoint. If heat is required, the ACR shall calculate the supply air temperature required to satisfy conditions. Once the supply air temperature is calculated it shall be compared to the supply air temperature sensor reading to determine the number of stages required to satisfy conditions. F. Heating-Face and Bypass: 1. CV: The heating routine shall modulate a Face and Bypass damper to prevent the space temperature from falling below the heating setpoint. The control shall calculate the supply air temperature and then modulate the damper based on this calculation and the actual supply air temperature. When the fan is off, the damper shall be positioned to the full bypass position and the heating valve shall be closed. The system shall be possible to maintain a minimum duct temperature by opening and closing the valve to maintain a minimum reference temperature to help protect the coil from a Freezing situation. For those systems that require a dehumidification cycle (see I/O summary and/or sequence of operation) the damper shall be modulated to maintain its supply air temperature setpoint when providing dehumidification if the heating coil is in the reheat position. 2. VAV: This routine shall modulate a Face and Bypass damper to prevent the controlling temperature from falling below the occupied/unoccupied heating setpoint. The Face and Bypass routine shall be used primarily for morning warm-up or occupied/unoccupied heating. When the supply fan is on, the PIC shall determine, based on the controlling temperature, if it is in a morning warm-up mode or if occupied/unoccupied heating is required. When the fan is off, the damper shall be positioned to the full bypass position and the heating valve shall be closed. The system shall be possible to maintain a minimum duct temperature by opening and closing the valve to maintain a minimum reference temperature to help protect the coil from a Freezing situation. For those systems that require a dehumidification cycle (see I/O summary and/or sequence of operation) the damper shall be modulated to maintain its supply air temperature setpoint when providing dehumidification, if the heating coil is in the reheat position. G. Cooling Coil Control: 1. CV: The cooling coil routine shall modulate the cooling coil valve to maintain the conditioned space’s cooling setpoint. The valve shall be closed whenever the space temperature is below the cooling setpoint. The dual loop PID control algorithm shall utilize the space sensor as the master sensor and the discharge sensor as the submaster sensor. The valve shall be closed whenever the system is indexed to UFC, providing heat, or if the supply fan is off. For those units that require dehumidification control (see I/O summary and/or the sequence of operation), the control valve shall open whenever the humidity sensor exceeds its (adjustable) humidity setpoint and calls for dehumidification. 2. VAV: The cooling coil routine shall modulate the cooling coil valve to maintain the desired supply air temperature setpoint. The dual loop PID control algorithm shall utilize the discharge sensor as the master and submaster sensor. A supply air reset algorithm shall reset the supply air temperature setpoint upward as the space temperature falls below the cooling setpoint. The return air temperature shall be used as a reset sensor based on a user configurable reset rate. The valve shall be closed whenever the system is indexed to UFC, providing heat, or if the supply fan is off. For those units that require dehumidification control (see I/O summary and/or the sequence of operation), the cooling coil control valve shall open whenever the humidity sensor exceeds it user adjustable humidity setpoint. H. Cooling Face and Bypass: 1. CV: The cooling coil routine shall modulate a Face and Bypass damper to prevent the space temperature from exceeding the cooling setpoint. The control shall calculate the required supply air temperature and then modulate the damper to keep the supply air temperature at its calculated value. When the fan is off, the dampers shall be positioned to the full bypass position and the chilled water valve shall be closed. For those systems that require a dehumidification cycle (see I/O summary and/or sequence of operation), the damper and valve shall be opened fully. 2. VAV: The cooling coil routine shall modulate a Face and Bypass damper to maintain the desired air temperature setpoint. A supply air reset algorithm shall reset the supply air temperature setpoint upward as the return air temperature falls below the cooling setpoint. The supply air temperature shall reset as a function of the return air temperature based on a user configurable reset rate. If the fan is off or UFC is active, the damper shall modulate to the full bypass position and the chilled water valve shall be closed. For those systems that require a dehumidification routine (see I/O summary and/or Sequence of operation), when the space humidity sensor exceeds its high limit setpoint, the dampers shall be positioned to the full face position with the chilled water valve open. I. DX Cooling Control (CV) only: This control routine shall be capable of regulating the DX cooling system (see plans and/or I/O summary for required number of stages). The DX cooling stages shall be energized and de-energized to prevent the space temperature from exceeding its desired setpoint. The stages shall remain off if the space temperature is below the setpoint or if the supply fan is off. Stages shall be enabled in sequence with a time delay for each stage. The algorithm shall include separate time delays appropriate for turning stages off. The ARC shall be capable of providing dehumidification (see I/O summary and/or sequence of operation for requirement). When the humidity sensor is above its setpoint the ACR shall enable DX to maintain a minimum submaster reference temperature value while still protecting the coil from freezing. DX control shall not be enabled when the system is indexed to UFC, or providing heat. If the supply fan is off, or a fan failure occurs, all stages of DX cooling shall be immediately disabled. The ARC shall be capable of providing an outside air temperature lockout to prevent DX cooling from starting during periods when the outside air temperature is colder than the operating range of the condensing unit and the conditions can be met by outside air. J. Mixed Air Damper Control: 1. CV: The mixed air damper routine shall modulate the outside, return and exhaust air dampers, as applicable. When an enthalpy comparison by the routine determines that the outside air conditions are unsuitable for atmospheric cooling, the dampers shall be positioned to admit an adjustable, minimum outside air percentage. When the enthalpy comparison determines that outside air conditions are suitable for atmospheric cooling, the mixed air dampers shall be modulated to maintain a space temperature that is between the heating and cooling setpoints in an effort to minimize the need for mechanical cooling or heating (the controller shall automatically provide this value based on the setpoints entered). The damper adjustment rate shall be automatically limited to prevent nuisance, low temperature thermostat tripping. During the unoccupied cycle and morning warm-up, the mixed air dampers shall be kept closed to outside and exhaust air and open to return air unless the system has been indexed to UFC. The minimum damper position shall be the greatest of the supplied configured minimum percentage position(s), as applicable, from the Indoor Air Quality routine or this routine, whichever is greatest. If the supply fan is off, the mixed air dampers shall be kept closed to outside and exhaust air and open to return air. 2. VAV: The mixed air damper routine shall modulate the outside, return, and exhaust air dampers as applicable. When an enthalpy comparison by the routine determines that outside air conditions are unsuitable for atmospheric cooling, the dampers shall be held at an adjustable minimum position or modulated to a minimum position determined by the IAQ routine, as applicable. When the enthalpy comparison determines that outside air conditions are suitable for atmospheric cooling, the mixed air dampers shall be modulated to maintain a mixed air temperature equal to the supply air temperature setpoint (plus any reset value) minus 4°F. For those systems with mechanical cooling, this routine shall insure that outside air is always fully utilized as the first stage of cooling (when available) and that the mechanical cooling is always disabled first as the load decreases. During the unoccupied cycle and morning warm-up, the mixed air dampers shall be kept closed to outside and exhaust air and open to return air, unless the system has been indexed to UFC. If the supply fan is off, the mixed air dampers shall be kept closed to outside and exhaust air and open to return air. The dampers shall also be capable of being modulated to maintain a desired temperature setpoint set by the operator. The Controller shall be capable of providing a protection feature that shall automatically limit the amount of outside air to prevent the mixed air temperature from falling below 48°F. 3. Two Position Damper Control: Two-position damper control shall be used to control two position outside dampers to provide minimum outside air ventilation. If the supply fan is off, the damper shall be closed. If the supply fan is on, the control shall determine if the unit is in the occupied mode. If the unit is in the occupied mode the dampers shall open. If the unit is in the unoccupied mode, the dampers shall remain closed; however, the dampers shall open when the unit is indexed to Unoccupied Free Cooling. K. Static Pressure Control: The ARC shall modulate the supply fan inlet guide vanes (IGV) or the supply fan motor drive to maintain the duct static pressure setpoint. When the supply fan is off, the IGV shall remain closed or the drive shall be reset to minimum speed. When the supply fan is on, the controller shall read the duct static pressure and the PID control algorithm shall compute the IGV position or drive output required. The controller shall compare the actual duct static pressure to the desired setpoint value and re-calculate the required signal output to the IGV or the drive. L. Indoor Air Quality (IAQ): The ARC shall be capable of monitoring and alarming one or two (see I/O summary for requirements) IAQ sensors or may be to used to maintain a IAQ setpoint (one for each sensor or sensor group value (e.g., highest zone CO2) by overriding the current minimum mixed air damper position when either IAQ sensor exceeds its operator adjustable setpoint. This routine shall also be subject to a field selectable low temperature override based on the mixed air temperature or outside air temperature (see I/O summary and/or sequence of operation for requirements). The IAQ routine shall be capable of suspending its damper override position based on space temperature and humidity. VAV units shall also include a supply air temperature check. M. Constant Outdoor Air (VAV Only): The ARC shall be capable of monitoring and maintaining a constant volume of outdoor air as long as the system airflow equals or exceeds the airflow setpoint. During occupied periods, the ARC shall monitor the amount of outdoor air entering the mixing box and shall compare that value to the outdoor airflow setpoint. The dampers shall modulate, as required, in order to achieve the desired airflow. If heating coil or Face and Bypass Heat is supplied, it will modulate as required to maintain the supply air temperature at the supply air temperature setpoint. If required, an adjustable maximum shall prevent excessive amounts of outdoor air from entering the unit during transient conditions, and a minimum mixed air temperature check shall prevent the mixed air temperature from falling below 48°F and possibly tripping the LTD. N. Two Speed Fan/VFD Control: The ARC shall include a two speed fan control algorithm to be used with two speed motors, or a single frequency drive algorithm with adjustable preset high/low CFM limits. Whenever the fan is off, or if the humidity exceeds the adjustable high limit, the fan speed shall be set to low. When the fan is on, the PIC shall determine if the space temperature is above the cooling setpoint, or below the heating setpoint, or if the mixed air dampers are providing maximum economizer operation. If any of these conditions exist, the fan shall be commanded to run at high speed. After the conditions have returned to normal (no heat or cool load) the fan shall be commanded back to the slow speed. O. Filter Status Control: The ARC shall monitor an airflow switch or switches, as applicable, measuring the differential pressure between the upstream and downstream side of the filter(s) for all units that list filter status within the I/O summary. When the filter becomes dirty or needs to be replaced, the airflow switch shall input a discrete signal to the ARC, that will in turn, generate an alarm at the Alarm Output Relay (as applicable), portable PC or EMS operator’s station, if tied into a network. P. Portable PC Local Interface: Each ARC shall include the inherent ability to be added to a network or to be modified without the addition of any external devices. If connected to a EMS network and/or if a Portable PC w/EMS software is plugged into the ARC, the operator shall have access to input setpoint and configuration data, display conditions, alarms, etc. Q. Network Compatible: The Retrofit Air Handler controller (ARC) shall have the resident capacity of connecting onto a communication network with other like controllers and communicating with other compatible microprocessor-based controllers and PCs. Controllers that do not include this resident capability without adding additional hardware are not acceptable. R. Network features: The ARC shall support the following network features: Data collection and transfer Interface to a local and/or remote EMS operator’s station Interface to portable PC or alarm printer Demand Limiting and Tenant Billing Dynamic Linkage to Air Terminals Interface to General Purpose Electronic Controllers (GPEC) to provide custom programming access Interface to Linkage Thermostat (CV only)