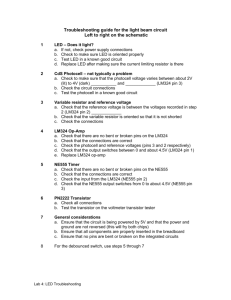

E101 LAB 3

advertisement

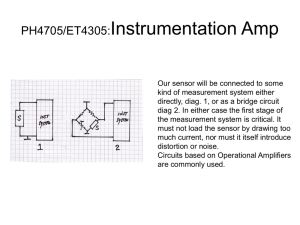

E102 LAB Temperature Control of Heated Block Temperature Controller Specifications Design, simulate and test a control system for temperature control of a heater block to satisfy the following specifications: 1. Heat the block from room temperature to 60C in less than three minutes with less than 1C overshoot and zero steady state error. 2. While operating at 60C, the control system must recover from a step disturbance in voltage input to the heater in less than two minutes with zero steady state error. Test Facility P2381 (45-1-23) Heater and Sensor Board Power Amp Power Op Amp Data Acquisition Terminal Block 4 wires go to breadboard Data Acquisition Ground (green) Temperature output (blue) 6V supply (red) Volt input (white) MATLAB Interface Testing and Data Acquisition with Real Time Windows Target (RTWT) A. Connection Setup 1. Ensure the board is connected to ground(green), the 6V power supply (red), the temperature signal output (blue) and the voltage input (white) as described in the previous slides. 2. Check that the power amp is connected with the banana plugs to the HP DC power supply (+/20V and common). 3. Turn on power supply and check that it is reading 20V and about 0.05A. B. Computer Setup 1. Log on to either ENG-ECF-2 or ENG-ECF-13 in the test facility User Name e102lab Password e102lab 2. Open E102Lab on the desktop. 3. Open heatercontrolmodel.mdl heatercontrol.mdl 0 w Manual Switch 1 1 wstep du /dt 0 0 r 60 D Derivative Analog Output 10 Manual Switch rstep P in1 out in2 1 s Anti -Windup Integrator Analog Input Analog Input National Instruments PCI-6014 [auto] Saturation Analog Output National Instruments PCI-6014 [auto] 0 I 1/.032 oC /V Scope Testing and Data Acquisition with Real Time Windows Target (RTWT) C. Controller Design and Test 1. Open heatercontrol.mdl. Set the setpoint manual switch to 0. Set the disturbance manual switch to 0. Enter your controller design values for P, I and D. Open Scope block 2. Choose menu Simulation=>Connect to Target. The MATLAB workspace will show “Model heatercontrol loaded” 3. Choose menu Simulation=>Start Real Time Code. The Scope block should display the control voltage input and the temperature output sampled at 1 s intervals. After about a minute to record ambient temperature, set the setpoint input switch to 60C. You should see the step voltage input on the scope and the DC power supply will register about 0.5A as the heating block switches on. As the control takes effect, the power supply will show a decreasing power input . Record the data until the output reaches steady state (about 5 minutes if your control design is working) * *RTWT is a bit buggy and occasionally crashes or sends you undecipherable error messages without any reason. Just restart the computer if this happens. It usually gets over its bad behavior. In the unlikely event that you get the following error message “checksum mismatch: Target code needs to be rebuilt”, choose menu Tools=>Real-Time Workshop=>Build Model. The command window will fill up with verbosity until you see “Successful Completion of Real Time Workshop build procedure”. Then continue with connecting to target as before. Testing and Data Acquisition with Real Time Windows Target (RTWT) C. Controller Design and Test (cont.) 4. Without changing the setpoint, set the disturbance manual switch to 1. You should see the voltage input drop on the scope and the power input drop from the power supply. Continue recording the data until the control system has recovered from the disturbance (about 2 minutes if your control design is working)* 5. On completing the disturbance test, set both the manual switches back to 0. Choose menu Simulation =>Stop Real Time Code. Your results will be stored in TemperatureVoltData in the MATLAB workspace. 6. Save your experimental results. (You may like to run the m-file TempVoltexport.m which creates a text file controldata.txt that you can save) 7. Switch off the power supply and log out. *Your time limit for running the total simulation is 1500s (25 min). After this all your recorded data in the MATLAB workspace is lost and the simulation starts recording data again starting at time 0. Optional: Build your own board E102 Lab Kit 1 Solderless Breadboard with wire leads 22k Resistor 10k Resistor LM324 Quad OpAmp chip LM35 Temperature Sensor 10 Ohm Aluminum Housed Resistor Heating Block Nut/bolt Circuit Diagram LM35 Vout 0.01T Vcc Gnd Vout o (T C) LM324 Assembly 1 Solder leads to 10 ohm resistor Attach LM35 sensor to back of resistor QuickTime™ and a TIFF (Uncompressed) decompressor are needed to see this picture. QuickTime™ and a TIFF (Uncompressed) decompressor are needed to see this picture. Assembly 2 Bend sensor pins and connect to board Final Assembly Connect temperature sensor and op amp