Pervious Concrete Pavement Study

advertisement

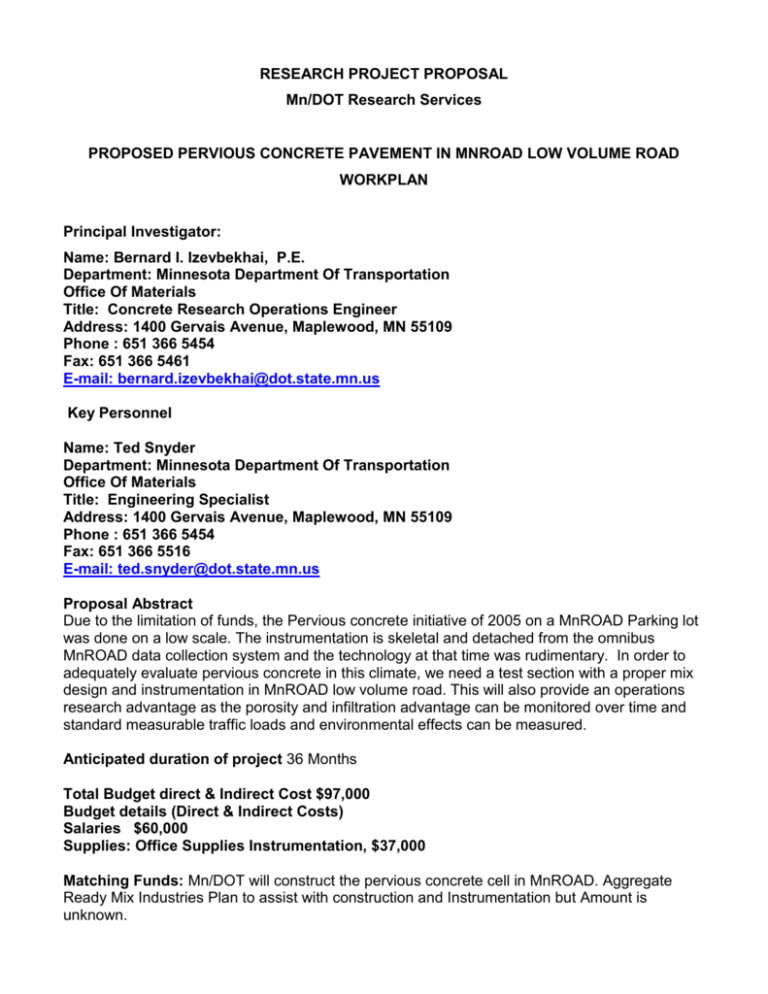

RESEARCH PROJECT PROPOSAL Mn/DOT Research Services PROPOSED PERVIOUS CONCRETE PAVEMENT IN MNROAD LOW VOLUME ROAD WORKPLAN Principal Investigator: Name: Bernard I. Izevbekhai, P.E. Department: Minnesota Department Of Transportation Office Of Materials Title: Concrete Research Operations Engineer Address: 1400 Gervais Avenue, Maplewood, MN 55109 Phone : 651 366 5454 Fax: 651 366 5461 E-mail: bernard.izevbekhai@dot.state.mn.us Key Personnel Name: Ted Snyder Department: Minnesota Department Of Transportation Office Of Materials Title: Engineering Specialist Address: 1400 Gervais Avenue, Maplewood, MN 55109 Phone : 651 366 5454 Fax: 651 366 5516 E-mail: ted.snyder@dot.state.mn.us Proposal Abstract Due to the limitation of funds, the Pervious concrete initiative of 2005 on a MnROAD Parking lot was done on a low scale. The instrumentation is skeletal and detached from the omnibus MnROAD data collection system and the technology at that time was rudimentary. In order to adequately evaluate pervious concrete in this climate, we need a test section with a proper mix design and instrumentation in MnROAD low volume road. This will also provide an operations research advantage as the porosity and infiltration advantage can be monitored over time and standard measurable traffic loads and environmental effects can be measured. Anticipated duration of project 36 Months Total Budget direct & Indirect Cost $97,000 Budget details (Direct & Indirect Costs) Salaries $60,000 Supplies: Office Supplies Instrumentation, $37,000 Matching Funds: Mn/DOT will construct the pervious concrete cell in MnROAD. Aggregate Ready Mix Industries Plan to assist with construction and Instrumentation but Amount is unknown. RESEARCH PROJECT WORKPLAN Mn/DOT Research Services Pervious Concrete Page 2 Research Matrix & Methods Construct and instrument a pervious concrete cell in the MnROAD low volume Roads. Create sub cells with different mix design types Based on the MnDOT 2005 initiative and the ISU 2005 report on Mix Design Development for Pervious Concrete in Cold Weather Climates. Provide an infiltration model for the pervious media. This includes characterizing the soils up to 20 ft deep and analyzing infiltration based on porosity of the various layers. Create a Hydrological model and validate. Determine actual freezing and thawing cycles and conduct freeze thaw ASTM 666 as well as surface condition survey. Monitor qualitatively and quantitatively for more than 5 years comparing Performance of pavement on clay to performance of pavement over Sand Observe and measure stress-strain response, freeze-thaw degradation and cracking or heaving. *** Subject a cast insitu panels to Minne-Alf testing at the U of M. Optional idea for advanced research Required Instrumentation Vibrating Wire SG Water Blocks Thermocouples Fig 2 Proposed Sensor tree (one per 100ft/per lane) To perform the proposed measurements and monitoring, the following instrumentation would be required: Strain Gauges, Vibrating wires, Invar Rods, Frost Pins, Infiltrometers, Thermocouples, RESEARCH PROJECT WORKPLAN Pervious Concrete Page 3 Mn/DOT Research Services Maturity data loggers and Proximate piezometer to capture aquiferous mounding. Other sensors include TC Thermocouples Manufactured by Geokon. VW- Vibrating Wire strain gauges TD - Time Domain Reflectometer MH- Moisture sensor/ Watermarks Flowmeters Tipping buckets and Infiltrometers Work plan 1. Task 1 Subsurface exploration flow modeling Structural Design and data collation An investigation of the current research initiatives, results and challenges in using pervious concrete to date. A review of literature that particularly discuss the performance in cold climates and in a freeze thaw environment. A review of the work done so far at Iowa State University CP Tech Center (laboratory efforts) and field performance so far in the Minnesota Efforts (Parking lot and Walkway. A summary report of Findings to be presented in a form that logically leads to a hypothesis for research needs. Task includes taking strategic borings for soils conductivity evaluation, and baseline for piezometer and contaminant levels. Perform a pavement design based on Heuristic modification of Design parameters from porosity and strength considerations derived from previous initiatives (Cell 64 MnROAD) and on the traffic loads computed from truck trips around the low volume loop. In this design, consideration is given to the performance of the section above the clay subgrade as a retention and gradual release pond whose reservoir is provided by the voids in the aggregate base as well as the porous concrete structure. Perform a mix design based on the work of Shaeffer et al (2005) using optimum aggregate size and porosity to enhance parameters of infiltration (hydraulic conductivity), noise attenuation and durability, Describe the subgrade soils and model the flow: Six borings will be taken on the overall study section. Of these 6 borings, 2 shall be taken on each of cells cell 24 25 and 26. Each of the borings shall be equipped with piezometers and automated piezometric / resistivity meters that shall be linked to the data collection system for monitoring. Deliverable for task 1: Power point presentation and summary report detailing the following: a) A literature survey of current trends and updates in pervious concrete. Justification of this study b) A Geotechnical report of the subsurface conditions the original piezometric (potentiometric) levels and the hydraulic conductivity. Modeling for the structure from RESEARCH PROJECT WORKPLAN Pervious Concrete Page 4 Mn/DOT Research Services pavement surface to the aquiferous stratum (strata). A hydraulic conductivity model of the Initial pavement structure c) A pavement design of the pavement structure and a mix design for the surfacing. d) Initial Noise and Ride measurement of existing cells 25 and 26 and the discussion of the ERD Files. Duration of Task September 2007 to December 2007 2) Task 2 Trial Mixing, Possible Mix redesign & Instrumentation Layout This involves lab evaluation of trial mixes for freeze thaw, compressive strength, porosity, flexural strength etc. It also involves the instrumentation plan designed in detail. In this task, a mix design of the pavement mix will be performed. One of the designs will be the standard optimum recommended by Schaeffer et al and the other design will be the Mn/DOT Cell 64 mix design for the best performing sub section. The trial mixes shall be done at an accredited laboratory in which the following tests will be performed: Unit weight will be measured and the rheological tests shall be limited to temperature and unit weight and shall not include slump tests. Compressive strength test and modulus of rupture tests shall be performed at 3-day 7-day 14 day and 28-day for each trial. Freeze thaw ASTM C-666 tests on the representative beams. Instrumentation layout will be performed with the following considerations: Harmonious and optimal Installation with the Bituminous cells and optimal selection of instrumentation to maximize effect and facilitate uniform testing. Instrumentation type Frequency and interval of installations will also be described Structural/ mechanical instrumentation will include: Thermocouples, water blocks, Time domain reflectometers and vibrating wire strain gauges and embedment sensors. Hydrological instrumentation include: lysometers, Tipping buckets, Piezometers and resistivity meters. Tension Infiltrometers. Deliverable for task 2: A power point presentation and a brief report detailing the following: Trial mix report and recommendation Layout of Instrumentation 3) Task 3 Test Section Construction Report This report discusses the construction process and documents materials (cement water aggregate sources, delivery times, admixture used and rheological properties. The report also records and discusses instrumentation types, installation process and layout. Report records description of environmental / storm water measurement devices: cross drains, lysometers and soil borings taken in the vicinity of the test sections. It discusses the adjoining control test cell that will serve as a baseline for hydraulic conductivity measurements as well as the mechanical and acoustic properties. RESEARCH PROJECT WORKPLAN Mn/DOT Research Services Pervious Concrete Page 5 This report will document the initial pavement surface characteristics measurements. Due to the unique nature of this pavement the sand volumetric technique ASTM E-965 cannot the used. However, the Mn/DOT laser-equipped ASTM Circular Track Meter will be used to measure and record Texture profiles. Deliverable for Task 3 : A Draft Construction and Instrumentation Report. A power point presentation. Task Duration : Date of Commencement of grading and base to 6 weeks from date of Paving. 4) Task 4 Report of Hydrological evaluations This task is aimed at examining the hydraulic a d hydrologic data mainly to provide a mid project evaluation of the test methods and frequency. Hydrological report includes: a. Description of Monitoring devices and related parameters b. Hydraulic Conductivity Tracking c. Water Quality Tracking Environmental sampling This involves Performance of groundwater analysis upstream versus downstream and compare. This involves controlled boring screening and sampling paying attention to deicing salts if applied and noting possible pollutants and contaminants d. Piezometric tappings and records. Test for mounding. Deliverables for task 4: Preliminary hydrological report including a critical evaluation of the hydraulic data collection process and hydraulic conductivity data. Duration Of task 4: 12th month since paving to 13th month and half since paving 5) Task 5. Continuous Monitoring and First Year Performance Report To fulfill this task, Falling Weight deflectometer tests will be conducted every 2 months on each of the 3 subcells every month. The deflection basin will be observed in these tests and a back calculation will be performed. The load levels will be 3000 lb 5000 lb, 7000lb and 9000lb. Testing will terminate at the load level (9000lb or less) if chaotic amplitudes are detected. To fulfill this task, noise, ride and texture measurements and splash and spray visibility index will be conducted 2 times a month for the first 2 months and Monthly thereafter every month. These will be analyzed independently and in comparison to the cells in the Pavement surface characteristics MnROAD Studies Construction and Pavement Surface Characteristics (Rehabilitation) MnROAD Study. Noise shall be measured with the on-Board Sound Intensity metric and ride will be measured with the Mn/DOT Light weight profiler. Texture will be measured with the laser-equipped device that can capture clogging by averaging lesser texture on account of reduced porosity. FWD: Strength Properties Report the mechanical properties from sensor readings FWD monitoring hydrological evaluations and surface rating and freeze thaw resistance in scaling and raveling RESEARCH PROJECT WORKPLAN Mn/DOT Research Services Pervious Concrete Page 6 Surface Properties: Noise Texture, Friction, Hydroplaning potential. Surface properties will be measured once a month and analyzed. A protocol for quantification of splash and spray and texture will be proposed. Tension Infiltrometers and Single Ringed Tube: Hydraulic conductivity Tension Infiltrometers shall be used to monitor hydraulic conductivity once a week in the first 2 months and once in 2 weeks until the snow and ice operation where the rate will once again be once a week. A ring will be installed in the concrete up to an inch below the pavement surface. Direct measurement of a 5-gallon bucket shall be times in this at the same rate of testing as the tension Infiltrometers. Sensor monitoring Sensor data will be hooked on the central data collection system. These will be requested as often as necessary. Maturity data loggers will be placed in the concrete and a maturity function for porous concrete will be monitored Deliverables for task 5: First year performance report, A power point presentation and a Data from Continuous Monitoring technical brief (Addendum to First Year performance report) Duration Of Task 5 Continuous Data Collection 13 months Task 5 reporting: 2 months after first year of construction Task 6 Draft final report Deliverable for task 6: A draft final report & Power point Presentation Duration of task 6 4 months Task 7 Final Report Technical Blurb benefit / Cost Analysis Deliverable for task 7: A final Report Published Report A final Technical Blurb Published (similar to executive Summary). To include strategies for long term research and monitoring and deployment Duration For task 7: 3 months *Deployment and Implementation process RESEARCH PROJECT WORKPLAN Pervious Concrete Page 7 Mn/DOT Research Services o Hold informational sessions with Engineers, Resident Engineers and materials Engineer as well as County Engineers, CPAM and the Academic community. o Work with the Concrete Engineering Unit to provide a rider in the Concrete Spec that would guide on the use of pervious concrete. o Work with Counties and Cities who are willing to embark on pervious concrete programs RESEARCH PROJECT WORKPLAN Mn/DOT Research Services Pervious Concrete Page 8 7 Timeline Based On Spring Construction Of pervious Concrete Pavement 1 August 07 DESCRIPTION Precedent network Contingent on assumed Pavement Construction Window COST↓ 17TASK 1 Subsurface exploration flow Modeling Structural Design $10,000 2 Trial Mix design and Instrumentation Layout $12,000 3 Construction & Instrumentation Report $10,000 4 PRELIMINARY Hydrological Evaluation Report $15,000 5 First year performance report $15,000 6 Monitoring and maintenance Continuous $10,000 7 Draft Final Report $15,000 8 Final Report, Tech Blurb $10,000 $97,000 2 3 CELL CONSTRUCTIONN QTR → 4 5 6 7 8 9 10 11 12 13 14 15 16 RESEARCH PROJECT WORKPLAN Mn/DOT Research Services Pervious Concrete Page 9 Appendix 1 Conceptual Instrumentation For Hydrologic evaluation Frequency : 1 per concrete Sub-cell Cylindrical Tube 8 inch Dia Pervious Concrete Porous Base Subgrade RESEARCH PROJECT WORKPLAN Mn/DOT Research Services Appendix 2 Pressure (Tension) Infiltrometers One per concrete Subcell Pervious Concrete Page 11 RESEARCH PROJECT WORKPLAN Mn/DOT Research Services This page is intentionally left blank Pervious Concrete Page 12 RESEARCH PROJECT WORKPLAN Mn/DOT Research Services Pervious Concrete Page 13 Appendix 3 Conceptual Cell layout with various subgrade types, pavement types but separated with transverse flow structures towards tipping buckets. This should be read in conjunction with a detailed instrumentation plan which is a deliverable item. Piezo 1 TB Pervious PCC Pervious HMA Clay Subgrade Clay Subgrade TB TB Piezo 4 Piezo 2 Piezo 3 Control Pervious HMA Pervious PCC Non-Pervious Surface Sand Subgrade Sand Subgrade TB Piezo 5 TB Piezo 6 TB