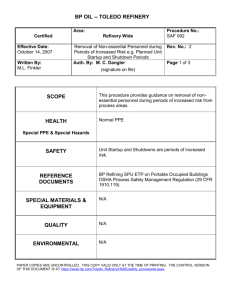

Certified

advertisement

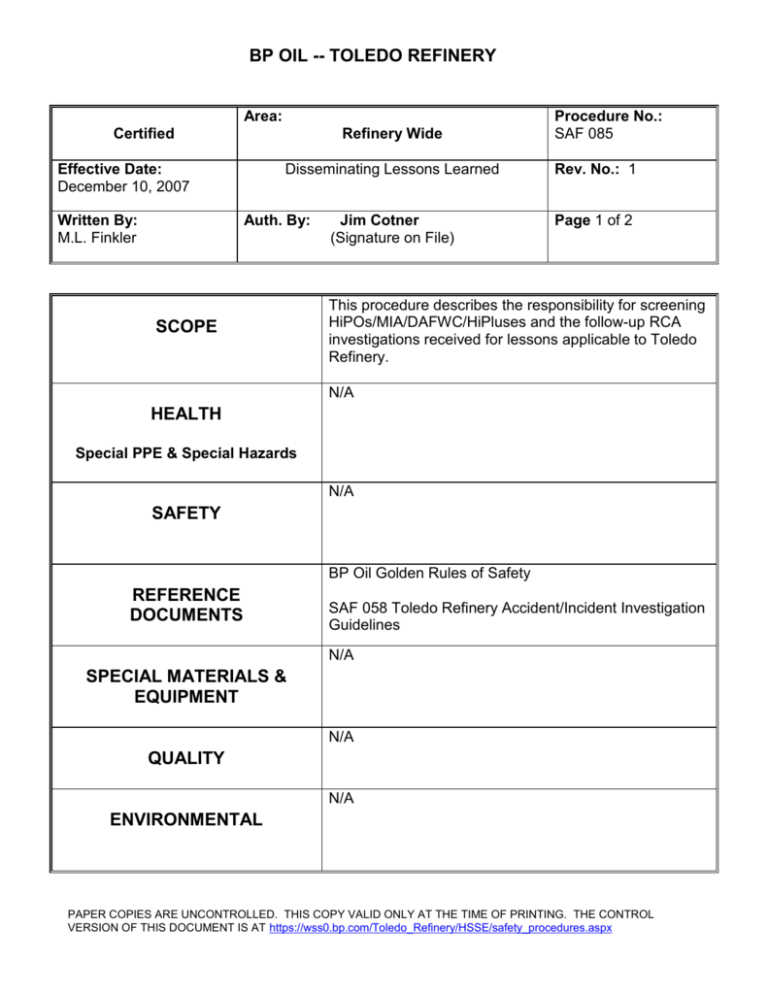

BP OIL -- TOLEDO REFINERY Area: Certified Refinery Wide Effective Date: December 10, 2007 Written By: M.L. Finkler Disseminating Lessons Learned Auth. By: SCOPE Jim Cotner (Signature on File) Procedure No.: SAF 085 Rev. No.: 1 Page 1 of 2 This procedure describes the responsibility for screening HiPOs/MIA/DAFWC/HiPluses and the follow-up RCA investigations received for lessons applicable to Toledo Refinery. N/A HEALTH Special PPE & Special Hazards N/A SAFETY BP Oil Golden Rules of Safety REFERENCE DOCUMENTS SAF 058 Toledo Refinery Accident/Incident Investigation Guidelines N/A SPECIAL MATERIALS & EQUIPMENT N/A QUALITY N/A ENVIRONMENTAL PAPER COPIES ARE UNCONTROLLED. THIS COPY VALID ONLY AT THE TIME OF PRINTING. THE CONTROL VERSION OF THIS DOCUMENT IS AT https://wss0.bp.com/Toledo_Refinery/HSSE/safety_procedures.aspx Procedure No. SAF 085 Rev. No. 0 OVERVIEW This procedure describes the responsibility for screening HiPOs/MIA/DAFWC/HiPluses and the follow-up RCA investigations received for lessons applicable to Toledo Refinery. Specifically, actions items from lessons learned will be identified, assigned and tracked to closure and included in % HSE Actions Completed KPI. 1.0 2.0 3.0 Screening Distribution Tracking 1.1 HiPOs/MIA/DAFWC/HiPluses and the follow-up RCA investigations received will be screened for applicability by the HSE Manager, Safety Team Leader or the Process Safety Coordinator. __1.2 All items from step 1.1 will be entered on a spreadsheet. __1.3 Lessons learned one page summary reports for HIPO, MIA, DAFWC, OSHA recordables, and any fire/explosion where the ERT was required to put the fire out will be reviewed by the Site Senior Management Team before distribution. 2.1 Incidents of a general concern will be distributed to specific departments within the refinery. 2.2 Incidents that are directly applicable to Toledo refinery will be placed in Traction and action items will be assigned with follow-up dates. 3.1 All items screened will be entered into a excel spreadsheet. The following information will be included. 1. Date of incident 2. BU 3. Country 4. Contact 5. Brief Incident description 6. Toledo Initial Action 7. Addition Action 8. Tr@ction # if entered 9. Comments 3.2 All items in Tr@ction will be tracked to closure __3.3 The tracking excel spreadsheet will be maintained at S:/common/lessons learned/Toledo Lessons Learned Procedure.xls __4.1 All Traction entries will be analyzed on a quarterly basis. The period will be for the previous year. Trends in incident type and cause will be determined. Results will be provided to the Site Senior Management Team along with recommendations for programs to improve performance in targeted areas. __ 4.2 The Safety Team Leader is accountable for ensuring step 4.1 is completed. 4.0 Trending THIS IS THE LAST PAGE Page 2 of 2 PAPER COPIES ARE UNCONTROLLED. THIS COPY VALID ONLY AT THE TIME OF PRINTING. THE CONTROL VERSION OF THIS DOCUMENT IS AT https://wss0.bp.com/Toledo_Refinery/HSSE/safety_procedures.aspx