5389

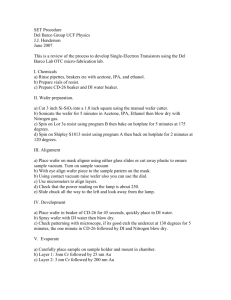

advertisement

Background Statement for SEMI Draft Document #5389A Revision to MF1982-1110, TEST METHODS FOR ANALYZING ORGANIC CONTAMINANTS ON SILICON WAFER SURFACES BY THERMAL DESORPTION GAS CHROMATOGRAPHY Notice: This background statement is not part of the balloted item. It is provided solely to assist the recipient in reaching an informed decision based on the rationale of the activity that preceded the creation of this Document. Notice: Recipients of this Document are invited to submit, with their comments, notification of any relevant patented technology or copyrighted items of which they are aware and to provide supporting documentation. In this context, “patented technology” is defined as technology for which a patent has issued or has been applied for. In the latter case, only publicly available information on the contents of the patent application is to be provided. Background SEMI standard document of MF1982 as description of the method of organic contamination measurement on the silicon wafer surface has wide influence over the user which is referred by ITRS road map. Now, TF had been decided to revise the MF1982 which was long time spending from establishment, problem for the measurement and immoderate description by TF reconsideration. Regarding the points of revision are correction about affect of measurement, simplifying of the expression and conformity of the SEMI style manual. This revision will be expected to active use for long time with easily understanding. The current standard document had been described the method for the measurement of organic contamination on the silicon wafer determined by GC-MS. And the expression of two methods (so-called A and B) for sample preparation had been described in this document by the deference of the shaping sample. TF had considered the problem of the current document of MF1982. Then we reached at the conclusion of three matters as followed. All organic contamination is not covered by GC-MS. The sample preparation can be combined expression about A and B method. And this document shall be changed the structure by referring the SEMI style manual. Concretely, TF would be performed to revise for this document as below, 1. Regarding the important concern for the measurement, it is described at new section as “Limitation”. 2. Removing the A and B method expression. 3. Reconsidering the whole document structure using SEMI style manual. This document had been revised from viewpoints of upper description. It was almost full alteration. Doc.4846 was submitted for Cycle 1, 2010 and passed the committee review in March. However, the Minority Report citing language flaws and its conflict with SEMI MF1982 was submitted. Then, the Japan Silicon Wafer Committee in June decided to overturn the adjudication result based on the Silicon GCS recommendation, and the document was returned to the Test Method Task Force. Language was reviewed and substantially improved as well as clarification of the difference between SEMI MF1982 and the proposed document was made. Doc.4846A was then submitted for Cycle 7 2010, however it failed the committee review during SEMICON Japan. The Task Force reviewed all the negatives and comments, and revised the document as appropriate. Doc.4846B was failed again for Cycle 7, 2011. The proposal of new standard (Doc 4846B) gives up and revises MF1982. Doc.5389 had been balloted in cycle 7 at 2012. However, this document had been failed. Because of the reject voters had pointed out the some beneficial comments. Then, Japan TF judged the “fail” for aim to better content. Japan TF had discussed about all reject voter’s comments. Also, TF had performed to continuously discussion with voters based on the TF comment by e-mail. Here, Japan TF decided to re-throw the Doc.5389A into the ballot cycle 7 at 2013. Doc.5389A was reached the consensus at the international Test Method Task Force at Aug. 28th and submitted in Japan Silicon Wafer Committee at Sep. 3rd. Review and Adjudication Information Task Force Review Group International Test Method TF Date Dec 4th 2013 Time & Time zone 3:00p.m.-5:00p.m. Japan Standard Time Committee Adjudications Global Silicon Wafer Committee Dec 5th 2013 10:30a.m. - 6:00 p.m. Japan Standard Time Location Makuhari Messe Makuhari Messe City, State/Country Chiba/Japan Chiba/Japan Leaders Ryuji Takeda (ryuji@sas-globalwafers.co.jp) Tetsuya Nakai (t-nakai@sumcosi.com) Peter Wagner (peter.wagner@onlinehome.de) Naoyuki J. Kawai (kawai.naoyuki@mail.uDinesh Gupta (dgupta@pacbell.net) tokyo.ac.jp) Standard staff Hirofumi Kanno (hkanno@semi.org) Hirofumi Kanno (hkanno@semi.org) Note: Additions are indicated by underline and deletions are indicated by strikethrough. Semiconductor Equipment and Materials International 3081 Zanker Road San Jose, CA 95134-2127 Phone: 408.943.6900, Fax: 408.943.7943 SEMI Draft Document #5389A Revision to SEMI MF1982-1110, TEST METHODS FOR ANALYZING ORGANIC CONTAMINANTS ON SILICON WAFER SURFACES BY THERMAL DESORPTION GAS CHROMATOGRAPHY 1 Purpose 1.1 Organics are present in many materials, such as plastics, lubricants, cleansers, soaps, and living tissues. Some of these compounds are volatile and others can become airborne through chemical reactions, heating, abrasion, or outgassing. Organic compounds are present in many materials such as parts and components for cleanrooms, carriers, FOUP, developers, and organic removers. Some of these organic compounds are volatile and some can be discharged into clean room environment through chemical reactions or by heating. Also they can transfer to wafers by direct contact or be left behind from solvent residues. Once present in clean facilities, they can deposit on wafer surfaces. The desorbed organic compounds can be transferred to wafers or reticles through the environment. Organics deposited on wafers can cause degradation haze, wafer surface tension changes, irregular oxidation rates, and other effects, such as counter-doping by organophosphorus compounds. Various organic compounds on wafer surfaces can cause a pseudo increase of the thickness of the native oxide film. Nonuniformity of the surface leads to nonuniform oxide on a wafer and causes degradation of the oxide breakdown voltage. It also causes not only wafers, but also the reticles or mirrors to haze. Identification of trace level organic contaminants is important in determining the source of the particular contamination. These test methods use the thermal desorption gas chromatography mass spectrometry (TD/GC-MS TD-GC)1,2 technique to characterize and quantify organics deposited on wafer surfaces. This is one of the reasons that control of organic compounds is required in a cleanroom environment or on wafer surfaces. This mandates test methods of organic compounds on wafer surfaces. TD/GC-MS is useful for qualitative and quantitative analysis of trace-level organic compounds adsorbed on wafer surfaces. 1.2 Monitoring of organic contamination on wafer surfaces also can be used to measure material outgassing for proper selection of cleanroom, construction, and wafer packaging materials. 2 Scope 2.1 These test methods cover the identification and quantification of organic contaminants on silicon wafer surfaces using a gas chromatograph interfaced to a mass spectrometer (GC-MS) or a phosphorus selective detector, or both. This test method covers the identification and quantification of organic compounds on wafer surfaces by using Gas Chromatography Mass Spectrometry (GC-MS). 2.2 These test methods describe the apparatus and related procedures for sample preparation and analyses by TDGC. This test method describes the procedures for sample preparation and analyses by Thermal Desorption Gas Chromatography (TD-GC). 2.3 The range of detection limits of these test methods depends on the target organic compounds, for example, the range of detection limits is from the subpicogram to the nanogram level of hydrocarbons (C 8 to C28) per square centimeter of silicon wafer surface. The range of lower detection limits of this test method depends on the species of organic compound. However, generally for organic compounds, it ranges from subpicogram to nanogram per square centimeter of silicon-wafer surface (pg/cm2 to ng/cm2). The lower detection limit when the molecular weight is assumed as 300 and carbon numbers as from 10 to 20 is in the range of 5e10–5e11 molecules/cm2, 1e12-1e13 C atoms/cm2. 2.4 These test methods can be used for polished silicon wafers, or silicon wafers with oxide films. This test method can be used for various materials depending on the purposes, but mainly for bare silicon wafers. 2.5 Two methods are described. Method A is performed on cleaved wafers. Method B is performed on full wafers. The detailed procedures of Method A and Method B as well as the differences between them, are described in § 6 and § 8. When testing wafers, full wafers are basically used. However, cleaved wafers can be accepted as long as it does not cause a significant drop in the sensitivity (from a quarter to a half of a wafer). 1 Fergason, L.A., “Analysis of Organic Impurities on Silicon Wafer Surfaces.” Microcontamination, April 1986: pp. 33–7. 2 Saga, K. and Hattori, T., “Identification and Removal of Trace Organic Contamination on Silicon Wafers Stored in Plastic Boxes,” Journal of Electrochemical Society (1996): pp. 3270–84. This is a Draft Document of the SEMI International Standards program. No material on this page is to be construed as an official or adopted Standard or Safety Gui deline. Permission is granted to reproduce and/or distribute this document, in whole or in part, only within the scope of SEMI International Standards committee (document development) activity. All other reproduction and/or distribution without the prior written consent of SEMI is prohibited. Page 1 Doc. 5389 SEMI LETTER (YELLOW) BALLOT DRAFT Document Number: 5389A Date: 2/12/2016 Semiconductor Equipment and Materials International 3081 Zanker Road San Jose, CA 95134-2127 Phone: 408.943.6900, Fax: 408.943.7943 2.6 Suitable safety precautions must be followed when handling organic solvents and compounds, hot materials subjected to propane flame, the propane flame itself, wafer thermal desorption systems, rapid thermal annealer, or a high temperature furnace. NOTICE: SEMI Standards and Safety Guidelines do not purport to address all safety issues associated with their use. It is the responsibility of the users of the Documents to establish appropriate safety and health practices, and determine the applicability of regulatory or other limitations prior to use. 3 Limitations3 3.1 Some organic compounds show difficulty in measuring by TD/GC-MS. These are volatile compounds, amines, polar compounds (fatty acids, etc.), and high-polymer organic compounds that degraded at 400°C or below. In the TD/GC-MS measurement above, high-polymer organic compounds or polar organic compounds tend to remain in the column or show themselves as broad peaks. Organic materials degraded at 400°C or below may be measured as other materials generated after the degradation. As organic phosphorus tends to remain and degrade, a combination of qualitative analysis by TOF-SIMS and quantitative analysis by Inductivity Coupled Plasma Mass Spectrometry (ICPMS) after organophosphorus degradation is desirable. For amines, qualitative and quantitative analysis by Capillary Electrophoresis (CE) or Capillary Electrophoresis Time-of-Flight Mass Spectrometry (CE/TOF-MS) is preferable. 4 Referenced Standards and Documents 4.1 SEMI Standard SEMI M59 — Terminology for Silicon Technology 4.2 ASTM Standard ASTM D6196 — Practice for Selection of Sorbents and Pumped Sampling/Thermal Desorption Analysis Procedures for Volatile Organic Compounds in Air34 4.3 ISO Standard5 ISO/DIS 14644-8 Classification of air cleanliness by chemical concentration ISO/FDIS 14644-10 Classification of surface cleanliness by chemical concentration 4.4 JACA Standard6 JACA No.43-2006 (Japan Air Cleaning Association Standard) Analysis of Surface Molecular Contaminants NOTICE: Unless otherwise indicated, all documents cited shall be the latest published versions. 5 Terminology 5.1 General acronyms, terms, and symbols related to silicon technology are listed and defined in SEMI M59. 5.2 Abbreviations Specific to this Standard 5.2.1 AED — atomic emission detector C16 ― n-hexadecane, n-C16H34 5.2.2 C16 — n-hexadecane (n-C16H34) C20 ― n-eicosane, n-C20H42 5.2.3 FID — flame ionization detector CE ― Capillary Electrophoresis 5.2.4 FPD — flame photometric detector CE/TOF-MS ― Capillary Electrophoresis Time-of-Flight Mass Spectrometry 3 T. Taira, S. Hiroshima, Y. Shiramizu et.al “Study of organic contaminants analysis using TD/GC-MS on silicon wafer surfaces” ECS Trans., 2008, Vol 16 (6), 237-248. 34 American Society for Testing and Materials, 100 Barr Harbor Drive, West Conshohocken, Pennsylvania 19428-2959, USA. Telephone: 610.832.9585; Fax: 610.832.9555; http://www.astm.org 5 International Organization for Standardization, ISO Central Secretariat, 1 rue de Varembé, Case postale 56, CH-1211 Geneva 20, Switzerland; Telephone: 41.22.749.01.11, Fax: 41.22.733.34.30, http://www.iso.ch 6 Japan Air Cleaning Association, Itobeni-Hamacho Building, 2-7-5 Nihonbashi-hamacho, Chuohku, Tokyo, 103-0007 JAPAN, TEL:+86-33665-5591, FAX:+86-3-3665-5593, http://www.jaca-1963.or.jp/ This is a Draft Document of the SEMI International Standards program. No material on this page is to be construed as an official or adopted Standard or Safety Gui deline. Permission is granted to reproduce and/or distribute this document, in whole or in part, only within the scope of SEMI International Standards committee (document development) activity. All other reproduction and/or distribution without the prior written consent of SEMI is prohibited. Page 2 Doc. 5389 SEMI LETTER (YELLOW) BALLOT DRAFT Document Number: 5389A Date: 2/12/2016 Semiconductor Equipment and Materials International 3081 Zanker Road San Jose, CA 95134-2127 Phone: 408.943.6900, Fax: 408.943.7943 5.2.5 GC — gas chromatography GC ― Gas Chromatography 5.2.6 GC-MS — gas chromatograph interfaced to a mass spectrometer GC-MS ― Gas Chromatography Mass Spectrometry 5.2.7 MS — mass spectrometer ICPMS ― Inductivity Coupled Plasma Mass Spectrometry 5.2.8 NPD — nitrogen/phosphorus thermionic ionization detector NA ― Avogadro’s Constant 5.2.9 TBP — tributyl phosphate (C4H9O)3PO TD ― Thermal Desorption 5.2.10 TCEP — tris (2-chloroethyl) phosphate (ClCH2CH2O)3PO TD-GC ― Chromatography Thermal Desorption Gas 5.2.11 TD — thermal desorption TD/GC-MS ― Thermal Desorption Gas Chromatography Mass Spectrometry 5.2.12 TP — total organophosphorus TOF-SIMS ― Time-of-Flight Secondary Ionization Mass Spectrometry 5.3 Definitions of Term Specific to this Standard Definitions 5.3.1 blank wafer — a thermally-treated wafer desorbed of any surface organic contaminants equipment blank ― equipment (analyzer) background level 5.3.2 reference wafer ― a wafer surface which is organic contamination free 6 Summary of Test Methods Overview 6.1 Method A Thermal Desorption and GC Analysis 6.1.1 Desorption and GC Analysis — The volatile organic contaminants on a wafer surface are desorbed thermally from the wafer surface in a wafer desorption oven and swept into a sample thermal desorption tube. The sample thermal desorption tube then is heated for a set period in the thermal desorption unit and the volatile organic contaminants desorbed from the sample thermal desorption tube are swept by a stream of helium to a cold trap where they are preconcentrated. At the end of this period, the cold trap is heated rapidly to release the trapped organics to the GC column head. Sample components then are separated and eluted out of the GC column. Then, a portion goes to a phosphorus selective detector and the remainder goes to a mass spectrometer (MS). Blank wafers are prepared by purging out any surface organic contaminants in a rapid thermal annealer or a high temperature furnace while a purge gas is flowing. The organic compounds on a wafer surface are thermally desorbed in a quartz chamber and trapped by absorbents. 6.1.2 Identification of Contaminants — Identification of individual unknown compounds is performed by correspondence of retention time of their peaks with that of known compounds. Correspondence of retention time on a single column should not be regarded as proof of identity. More precise identification of individual unknown compounds is performed with MS by matching their fragmentation patterns with mass spectra of known compounds in the spectral library. The absorbents are kept in an inert gas environment such as He or N 2 for certain time to thermally desorb the organic compounds trapped in the absorbents and are then cooled down rapidly in a cold trap to condense the organic compounds. 6.1.3 Quantification — Quantification of total organics is based on the comparison of the integrated total peak area of the sample peaks with the area of the external standard compound, n-hexadecane (n-C16H34) [C16]. Total organophosphorus content in a sample is quantified by comparing the sample signal integrated from the phosphorus selective detector with the signal of the phosphorus standard compound, tris (2-chloroethyl) phosphate (TCEP) or tributyl phosphate (TBP). Specified range of standards is measured periodically, and the result is reported with blank wafer data. The cold trap is heated rapidly to release the trapped organic compounds into the GC column head. 6.1.4 Each component of the organic compounds is separated in the GC column. 6.1.5 Each separated component is lead to the mass spectrometer. Identification of individual unknown compounds is performed by matching patterns with mass-spectra library patterns. 6.1.6 Quantification is based on the integrated total peak area of each component compared with those of C16 or C20 as the standard. This is a Draft Document of the SEMI International Standards program. No material on this page is to be construed as an official or adopted Standard or Safety Gui deline. Permission is granted to reproduce and/or distribute this document, in whole or in part, only within the scope of SEMI International Standards committee (document development) activity. All other reproduction and/or distribution without the prior written consent of SEMI is prohibited. Page 3 Doc. 5389 SEMI LETTER (YELLOW) BALLOT DRAFT Document Number: 5389A Date: 2/12/2016 Semiconductor Equipment and Materials International 3081 Zanker Road San Jose, CA 95134-2127 Phone: 408.943.6900, Fax: 408.943.7943 6.1.7 Individual unknown organic compounds cannot be identified by retention time alone in the separation analysis by GC. It should be made by searching individual mass and library patterns. 6.2 Method B 6.2.1 Desorption and GC Analysis — The volatile organic contaminants on a wafer surface are desorbed thermally from the wafer surface in a quartz chamber unit and swept into a glass TD tube. The glass TD tube then is heated for a set period and a stream of helium sweeps the volatile organic contaminants desorbed from the glass TD tube to a cold trap where they are preconcentrated. At the end of this period, the cold trap is heated rapidly to release the trapped organics to the GC column head. Sample components then are separated and eluted out of the GC column. Then, a portion goes to a phosphorus selective detector and the remainder goes to a MS. Blank wafers are prepared by purging out any surface organic contaminants in the heated quartz chamber unit, while helium gas is flowing as a purge gas. 6.2.2 Identification of Contaminants — Identification of individual unknown compounds is performed by correspondence of retention time of their peaks with that of known compounds. Correspondence of retention time on a single column should not be regarded as a proof of identity. More precise identification of individual unknown compounds is performed with MS by matching their fragmentation patterns with mass spectra of known compounds in the spectral library. 6.2.3 Quantification — Quantification of total organics is based on the comparison of the integrated total peak area of the sample peaks with the area of the external standard compound, C16. Total organophosphorus content in a sample is quantified by comparing the sample signal integrated from a phosphorus selective detector with the signal of the phosphorus standard compound, tris-(2-chloroethyl)-phosphate (TCEP) or tributyl phosphate (TBP). Specified range of standards is measured periodically, and the result is reported with blank wafer data. 7 Apparatus 7.1 Method A TD/GC-MS 7.1.1 GC Instrument utilizing a capillary column to separate a wide variety of organic compounds coupled to a MS, or a phosphorus selective detector, or both. Examples of phosphorus selective detectors are flame photometric detector (FPD), and atomic emission detector (AED). The nitrogen/phosphorus thermionic ionization detector (NPD) also responds to nitrogen containing compounds. GC-MS (e) column― uses a general-purpose fused-silica capillary column. As a liquid phase, nonpolar 100%-Dimethylpolysiloxane, less polar 5%-Phenyl 95%Methylpolysiloxane, and polar 50%-Diphenyl 50%-Dimethylpolysilarylene can be used. NOTE 1: A NPD may also be used as a phosphorus selective detector. This type of detector also responds to nitrogen containing compounds. If an NPD is used, the total organophosphorus reported should exclude any signals due to nitrogen containing compounds. Often, identification from the mass spectra can be used to determine whether compound contains nitrogen or phosphorus, or both. 7.1.2 Sample Thermal Desorption Tubes — Stainless-steel tubes packed with adsorbent medium, are used to trap compounds of interest and release them onto a thermal desorption unit. Chamber Unit (a) ― desorbs organic compounds on wafer surface and traps them in a trap tube. NOTE 2: Note that stainless steel is catalytically active and can corrode with time, affecting recovery for some compounds. In this case, deactivated stainless steel, glass, or quartz tubes also can be used. Several adsorbent materials can be used for trapping organic compounds desorbed from silicon wafer samples. Some examples are activated carbon, graphitized carbon, and poly(2,6-diphenyl-p-phenylene oxide). 7.1.3 A thermal desorption unit is used to desorb organics from sample thermal desorption tubes. The thermal desorption unit is coupled to the GC instrument via a heated transfer line, for example, heated to 225°C or above. Chamber (b) ― should be purged with an inert gas (He or N2) to be free of organic compounds. Use a reference wafer to check. 7.1.4 A thermal annealer or a high temperature furnace is used to obtain a blank wafer (see ¶ 8.1.1.2). Trap Tube (c) ― is filled with an absorbent. Graphitized carbon, poly (2,6-diphenyl-p-phenylene oxide) are some of the examples of an absorbent. It collects organic compounds desorbed from wafers and then thermally desorbs them to a cold trap 7.1.5 A temperature controllable wafer desorption oven is used to hold and heat a wafer desorption tube. Cold Trap (d) ― cools down rapidly to condense organic compounds desorbed from the trap tube and transports them into the gas chromatography by rapid heating This is a Draft Document of the SEMI International Standards program. No material on this page is to be construed as an official or adopted Standard or Safety Gui deline. Permission is granted to reproduce and/or distribute this document, in whole or in part, only within the scope of SEMI International Standards committee (document development) activity. All other reproduction and/or distribution without the prior written consent of SEMI is prohibited. Page 4 Doc. 5389 SEMI LETTER (YELLOW) BALLOT DRAFT Document Number: 5389A Date: 2/12/2016 Semiconductor Equipment and Materials International 3081 Zanker Road San Jose, CA 95134-2127 Phone: 408.943.6900, Fax: 408.943.7943 7.1.6 Wafer Desorption Tube — A stainless-steel tube with an approximate dimension: 12.7 mm (0.5 in.) in outer diameter, 9.53 mm (0.375 in.) in inner diameter and 254 mm (10 in.) in length (see Figure 1) is used to desorb organics from cleaved wafers. Larger tubes may be used for larger wafer sizes and to increase the sensitivity of the test (see Note 2). 1. 2. 3. 4. 5. Sample thermal desorption tube Fitting Wafer desorption oven Quick connect male end Quick connect female end Wafer Back side Exhaust Furnace (a) Chamber Unit purge purge Quartz Chamber (b) Chamber Pump He gas Carrier gas (d) Cold Trap (e) GC-MS Cryo Unit Trap tube MS Wafer surface Valve Valve (c) Trap Tube Column GC データ処理部 Data Processing ライブラリー Block Library Figure 1 Schematic of Wafer Desorption Setup Conceptual Diagram of TD/GC-MS 7.1.7 Analytical Balance. 7.1.8 Quartz Plate and Carbide-Tipped Scribe, used to cleave wafer samples. 7.1.9 Quick Connect, used to connect a nitrogen line to the wafer desorption tube. 7.2 Method B 7.2.1 GC Instrument utilizing a capillary column to separate a wide variety of organic compounds, coupled to a mass spectrometer (MS) or a phosphorus selective detector, or both. Examples of phosphorus selective detectors are flame photometric detector (FPD), atomic emission detector (AED), or nitrogen/phosphorus thermionic ionization detector (NPD). The nitrogen/phosphorus thermionic ionization detector (NPD) also responds to nitrogen containing compounds (see Note 1). 7.2.2 A quartz chamber unit is used to desorb organic contaminants from the wafer surface and transfer them to a glass TD tube (see Figure 2). This is a Draft Document of the SEMI International Standards program. No material on this page is to be construed as an official or adopted Standard or Safety Gui deline. Permission is granted to reproduce and/or distribute this document, in whole or in part, only within the scope of SEMI International Standards committee (document development) activity. All other reproduction and/or distribution without the prior written consent of SEMI is prohibited. Page 5 Doc. 5389 SEMI LETTER (YELLOW) BALLOT DRAFT Document Number: 5389A Date: 2/12/2016 Semiconductor Equipment and Materials International 3081 Zanker Road San Jose, CA 95134-2127 Phone: 408.943.6900, Fax: 408.943.7943 1. 2. 3. 4. 5. LETTER (YELLOW) BALLOT DRAFT Document Number: 5389A Date: 2/12/2016 Quartz chamber Silicon wafer Fitting Fitting Fitting Figure 2 Schematic of Quartz Chamber 7.2.3 The quartz chamber may also be used to purge out any organic contaminants from a blank wafer. 7.2.4 A glass TD tube packed with adsorbent medium is used to trap compounds of interest and release them onto a cold trap. Several adsorbent materials can be used for trapping organic compounds desorbed from silicon wafer samples. Some examples are activated carbon, graphitized carbon, and poly (2,6-diphenyl-p-phenylene oxide). 7.2.5 A cold trap is used to concentrate organics desorbed from glass TD tube and release the organics to a GC instrument by rapid heating. 8 Procedure 8.1 Method A Sample Handling and Preparation 8.1.1 Sample Handling and Preparation: Care shall be always taken to prevent secondary contamination during sample handling. The reference shall be a cleaned organic-contaminants-free wafer. The wafer which is removed of organic compounds by heat treatment may also be used as a reference wafer. 8.1.1.1 At all times, avoid manual handling of samples for analysis to prevent any secondary contamination of samples. Use stainless steel tweezers for sample preparation. Use a propane torch to flame stainless steel tweezers, weigh boats, and other accessories that come into direct contact with the sample before their usage. 8.1.1.2 Thermally debsorb any organics from blank wafers in a rapid thermal annealer or a high temperature furnace. In order to desorb any organics from blank wafers, the temperature of a rapid thermal annealer is kept at 900°C for 15 s, or the temperature of a high temperature furnace is kept at 700°C for 30 minutes. Heating under air or oxygen makes a consistent organic-free SiO2 surface. Place the thermally treated blank wafers directly into petri dishes and wrap the dishes with organic-free aluminum foil. 8.1.2 Wafer Desorption: 8.1.2.1 Clean and precondition sample TD tubes in accordance with ASTM D6196 prior to attaching to the wafer desorption tube. 8.1.2.2 Turn on the temperature controller for the wafer desorption oven and wait for the temperature to reach 275°C. This is a Draft Document of the SEMI International Standards program. No material on this page is to be construed as an official or adopted Standard or Safety Gui deline. Permission is granted to reproduce and/or distribute this document, in whole or in part, only within the scope of SEMI International Standards committee (document development) activity. All other reproduction and/or distribution without the prior written consent of SEMI is prohibited. Page 6 Doc. 5389 SEMI Semiconductor Equipment and Materials International 3081 Zanker Road San Jose, CA 95134-2127 Phone: 408.943.6900, Fax: 408.943.7943 8.1.2.3 Cleave the wafer sample into strips about 5–7 mm wide by scribing a line on the wafer where one wants it to break and then placing it on a straight wire and breaking it along the scribed line. The portion of the wafer sample needed for the analysis changes with the size of the wafer. For a 100-mm wafer, about half of its surface area is needed. Larger samples (having larger surface area) may be used to increase the sensitivity of the test. 8.1.2.4 Place the wafer strips of wafer into the wafer desorption tube. Attach a sample TD tube to the side of the wafer desorption tube. Connect the other end of the wafer desorption tube to a nitrogen line with a flow of 15– 100 mL/min. 8.1.2.5 Place the wafer desorption tube in the oven and heat it for 30 minutes at 275°C. This allows the volatile organics to be thermally desorbed from the sample wafer and transferred to the sample TD tube. 8.1.2.6 Seal both ends of the sample TD tube into the TD unit or by using caps if the TD-GC system is automated. Tubes must not be left open and exposed to the laboratory atmosphere. The end caps should be made of a material that has low outgassing and low reactivity properties, such as polytetrafluoroethylene (PTFE), or stainless steel. 8.1.2.7 Analyze a blank wafer at least daily. Use a blank wafer treated with the same desorption procedure just described. Report blank data with the sample data. 8.1.3 GC Analysis: 8.1.3.1 Place the sample TD tube, which contains organic contaminants desorbed from the wafer, onto the TD unit. Enter the sample information into the computer, and start the GC analysis. 8.1.3.2 Flow the helium carrier gas through the sample TD tube during primary desorption. Heat the sample TD tube and sweep out the target organics contained in the sample to a cold trap where they are preconcentrated. Two recommended conditions for heating the sample desorption tube are as follows. When graphitized carbon is used as adsorbent material, heat the tube to 400°C and hold at 400°C for 15 minutes. When poly (2,6-diphenyl-p-phenylene oxide) is used as adsorbent material, heat the tube to 270°C and hold at 270°C for 15 minutes. Cold trap parameters, that is, sorbent, sold temperature, etc., should be selected such that all target analytes are retained quantitatively throughout the tube desorption process, for example, using a cold trap temperature of −30°C. Refer to ASTM D6196 for a method for testing desorption efficiency and analyte recovery. At the end of this period, heat the cold trap rapidly to 300°C to release the target organics to the GC column head. NOTE 3: For higher sensitivity analysis, larger sample sizes can be used, but clogging by water is possible. In this case, a subambient cold trap with an adsorbent may be used and maintained higher than 0°C during trapping to prevent freeze-up of trap. 8.1.3.3 Separate volatile organics desorbed from the sample TD tube by an appropriate column temperature program. Two recommended temperature programs are as follows. For high resolution analysis, using polydimethylsiloxane-coated column (60 m by 0.25 mm by 0.25–m film thickness), heat the column from 40°C– 280°C at a rate of 10°C/min and hold the temperature at 280°C for 16 minutes. For rapid analysis, using polydimethylsiloxane-coated column (25 m by 0.32 mm by 0.52–m film thickness), heat the column from 30°C– 265°C at a rate of 12.5°C/min and hold the temperature at 265°C for 16 minutes. 8.1.3.4 Use C16 as a standard for total organic analysis 4. Use TCEP or TBP, as a standard for organophosphorus analysis (see ¶ 7.1.1). These standards are introduced into the GC system from a precleaned sample thermal desorption tube. Two-point calibration method is recommended for checking the instrument performance. Recommended standards are two different concentrations of C16 for total organic analysis; and, two different concentrations of TCEP for total organophosphorus analysis. Recommended frequency of these measurements is at least once a week. NOTE 4: AED and FID are recommended for accurate total carbon quantification. 8.1.4 Quantification: 8.1.4.1 Obtain each area below for the calculation of total organic contaminants. Obtain total organic contaminants of the sample wafer (As) by summing up all the peak areas integrated from GC-AED, FID, or MS chromatogram of the sample wafer. Obtain total area of the blank wafer (Ab) by summing up all the peak areas integrated from GCAED, FID, or MS chromatogram of the blank wafer. Obtain the area of the standard peak (Ac) integrated from GCAED, FID, or MS chromatogram of the standard sample. 8.1.4.2 Obtain each area below for the calculation of total organophosphorus (TP). Obtain total area of phosphorus compounds of the sample wafer (As) by summing up all the peak areas integrated from GC-(phosphorus selective This is a Draft Document of the SEMI International Standards program. No material on this page is to be construed as an official or adopted Standard or Safety Gui deline. Permission is granted to reproduce and/or distribute this document, in whole or in part, only within the scope of SEMI International Standards committee (document development) activity. All other reproduction and/or distribution without the prior written consent of SEMI is prohibited. Page 7 Doc. 5389 SEMI LETTER (YELLOW) BALLOT DRAFT Document Number: 5389A Date: 2/12/2016 Semiconductor Equipment and Materials International 3081 Zanker Road San Jose, CA 95134-2127 Phone: 408.943.6900, Fax: 408.943.7943 detector) chromatogram of the sample wafer. Obtain total area of the blank wafer (Ab) by summing up all the peak areas integrated from GC-(phosphorus selective detector) chromatogram of the blank wafer. Obtain the area of the standard peak (Ap) integrated from GC-(phosphorus selective detector) chromatogram of the standard sample. 8.1.4.3 Before starting analysis, weigh and get the total weight of each sample wafer to be tested, and also the weight of unused part of each wafer. These weights are used for the calculation of total organic contaminants and total organophosphorus (TP). 8.2 Method B Desorption of Organic Compounds from the Wafer 8.2.1 Sample Handling and Preparation: Set a sample wafer in the chamber (b). In this case, a full wafer is assumed as the sample wafer, but it can be a wafer cut-down to a degree so as not to cause sensitivity degradation (about half to quarter of full size). The wafer shall be set after all the silicon chips generated during cutting are removed. 8.2.1.1 At all times, avoid manual handling of samples for analysis to prevent any secondary contamination of samples. Use stainless steel tweezers for sample preparation. Use a propane torch to flame stainless steel tweezers and other accessories that come into direct contact with the sample before their usage. 8.2.1.2 Thermally desorb any surface organic contaminants from blank wafers by purging them out in a heated quartz chamber unit while helium gas is flowing as a purge gas. Recommended conditions for preparing blank wafers are to heat them for 30 minutes in the quartz chamber kept at 700°C. Heating under air or oxygen makes a consistent organic-free SiO2 surface. 8.2.2 Wafer Desorption: Fill inert gas (He or N2) in the chamber and raise the chamber temperature from initial temperature (about 40°C or less) to about 400°C. Rate of the temperature rise will be about 10–30°C/min and soak at 400°C for 10–30 min. Organic compounds is thermally desorbed from the wafer and captured in the trap tube. 8.2.2.1 Enter the analytical information into the quarts chamber unit, cold trap and GC. Wait for the system to be stabilized. Place the sample wafer into the quartz chamber unit and start it. Supply helium gas into the quartz chamber and heat the chamber from initial temperature (40°C or lower) to 400°C at a rate of 10°C–30°C/min, and hold the temperature for 15 minutes. Sweep out the volatiles contained in the sample to a glass TD tube where they are adsorbed. 8.2.2.2 Analyze a blank wafer at least daily. Report blank data with the sample data. 8.2.3 GC Analysis: Test the reference wafer at least once a day. Report the data of the sample wafer and the reference wafer. 8.2.3.1 Heat the glass TD tube and sweep out the target organics adsorbed in the tube to a cold trap where they are preconcentrated. Two recommended conditions for heating the glass TD tube are as follows: When graphitized carbon is used as adsorbent material, heat the tube to 400°C and hold at 400°C for 15 minutes. When poly (2,6-diphenyl-p-phenylene oxide) is used as adsorbent material, heat the tube to 270°C and hold for 15 minutes. 8.2.3.2 Select cold trap parameters; that is, sorbent, cold temperature, etc., such that all target analytes are quantitatively retained throughout the tube desorption process, for example using a cold trap temperature of −130°C. Refer to ASTM D6196 for a method for testing desorption efficiency and analyte recovery. At the end of this period, heat the cold trap rapidly to 300°C to release the target organics to the GC column head. 8.2.3.3 Separate volatile organics desorbed from the glass TD tube by an appropriate column temperature program. Two recommended temperature programs are as follows. For high resolution analysis, use a polydimethylsiloxane coated column (60 m by 0.25 mm by 0.25-m film thickness), heat the column from 40°C–280°C at a rate of 10°C/min and hold the temperature at 280°C for 16 minutes. For rapid analysis, use a polydimethylsiloxane coated column (25 m by 0.32 mm by 0.52-m film thickness), heat the column from 30°C–265°C at a rate of 12.5°C/min and hold the temperature at 265°C for 16 minutes. 8.2.3.4 Use C16 as a standard for total organic analysis (see Note 4). Use TCEP or TBP, as a standard for organophosphorus analysis (see ¶ 7.1.1). These standards are introduced into the GC system from a precleaned wafer. A two-point calibration method is recommended for checking the instrument performance. Recommended standards are two different concentrations of C16 for total organic analysis; and two different concentrations of TCEP for total organophosphorus analysis. Recommended frequency of these measurements is at least once a week. This is a Draft Document of the SEMI International Standards program. No material on this page is to be construed as an official or adopted Standard or Safety Gui deline. Permission is granted to reproduce and/or distribute this document, in whole or in part, only within the scope of SEMI International Standards committee (document development) activity. All other reproduction and/or distribution without the prior written consent of SEMI is prohibited. Page 8 Doc. 5389 SEMI LETTER (YELLOW) BALLOT DRAFT Document Number: 5389A Date: 2/12/2016 Semiconductor Equipment and Materials International 3081 Zanker Road San Jose, CA 95134-2127 Phone: 408.943.6900, Fax: 408.943.7943 8.2.4 Quantification: 8.2.4.1 Obtain each area below for the calculation of total organic contaminants. Obtain total area of organic contaminants of the sample wafer (As) by summing up all the peak areas integrated from GC-AED, FID, or MS chromatogram of the sample wafer. Obtain total area of the blank wafer (Ab) by summing up all the peak areas integrated from GC-AED, FID, or MS chromatogram of the blank wafer. Obtain the area of the standard peak (Ac) integrated from GC-AED, FID, or MS chromatogram of the standard sample. 8.2.4.2 Obtain each area below for the calculation of total organophosphorus (TP). Obtain total area of phosphorus compounds of the sample wafer (As) by summing up all the peak areas integrated from GC-(phosphorus selective detector) chromatogram of the sample wafer. Obtain total area of the blank wafer (Ab) by summing up all the peak areas integrated from GC-(phosphorus selective detector) chromatogram of the blank wafer. Obtain the area of the standard peak (Ap) integrated from GC-(phosphorus selective detector) chromatogram of the standard sample. 8.3 GC-MS Analysis 8.3.1 Absorbents in the trap tube (c) is heated to about 300°C and soaked for 10–20 minutes. 8.3.2 Cool down the cold trap (d) to about -30 to -130°C and then heated up rapidly to about 300°C. 8.3.3 Heat up the trap tube (c) to desorb the organic compounds and condense them in the cold trap (d). Then rapidly heat the trap to send the organic compounds to GC-MS (e). 8.4 Semiquantification/ Quantification 8.4.1 Use C16 or C20 to semi-quantify. In some cases, the organic compound to be tested can be used for quantification. Drop the material directly onto the wafer or introduce it from the Trap tube (c) directly into the GCMS(e). A test involving multiple levels of concentration is recommended. The recommended frequency of measurement is at least once a week. 9 Calculation 9.1 Method A Calculation of Total Organic Contaminant areal concentration on one side of wafers, ng/cm2: 9.1.1 Calculation of Total Organic Contaminants: Total organic contaminants are calculated using equations as follows: TO As Ab 1 Wc Ac Sw where: TO = total organic contaminants, ng C16 or C20 equivalent/cm2, As = total area integrated from GC-MS chromatogram of the sample wafer, Ab = total area integrated from GC-MS chromatogram of the reference wafer, Ac = total area integrated from GC-MS chromatogram of the standard peak, Wc = weight of C16 or C20 standard injected onto the wafer, ng, Sw = one surface area of the wafer sample, cm2. (1) 9.1.1.1 When AED or FID is used: This is a Draft Document of the SEMI International Standards program. No material on this page is to be construed as an official or adopted Standard or Safety Gui deline. Permission is granted to reproduce and/or distribute this document, in whole or in part, only within the scope of SEMI International Standards committee (document development) activity. All other reproduction and/or distribution without the prior written consent of SEMI is prohibited. Page 9 Doc. 5389 SEMI LETTER (YELLOW) BALLOT DRAFT Document Number: 5389A Date: 2/12/2016 Semiconductor Equipment and Materials International 3081 Zanker Road San Jose, CA 95134-2127 Phone: 408.943.6900, Fax: 408.943.7943 As Ab Wc 10 9 1 6.02 10 23 16 Ac MWc Sw F (1) where: TC As Ab Ac Wc MWc Sw F WT WU = = = = = = = = = = total organic carbon, C atoms/cm2, total area integrated from GC-AED or FID chromatogram of the sample wafer for carbon compounds, total area integrated from GC-AED or FID chromatogram of the blank wafer (see Note 5), total area integrated from GC-AED or FID chromatogram of the standard peak, weight of C16 standard injected onto the standard tube, ng, molecular weight of C16 = 226.45, total area of the wafer sample, cm2, conversion factor = (WT − WU)/WT, total weight of the wafer, g, and weight of unused part of the wafer, g. NOTE 5: In these calculations, blank subtraction (Ab) is optional. 9.1.1.2 When MS is used: TO As Ab 1 Wc Ac Sw F (2) where: TO As Ab Ac Wc Sw F WT WU = = = = = = = = = total organic contaminants, ng C16 equivalent/cm2, total area integrated from GC-MS chromatogram of the sample wafer (see Note 6), total area integrated from GC-MS chromatogram of the blank wafer (see Note 5), total area integrated from GC-MS chromatogram of the standard peak, weight of C16 standard injected onto the standard tube, ng, total area of the wafer sample, cm2, conversion factor = (WT − WU)/WT, total weight of wafer, g, and weight of unused part of the wafer, g. NOTE 6: The recommended mass range to be scanned is 33–700 amu. 9.1.2 Calculation of TP: Assuming molecular weight as 300, total organic contaminants are calculated using equations as follows: TP 9 As Ab W p 10 1 6.02 10 23 Ap MW p Sw F (3) where: TP As Ab Ap Wp = total organophosphorus, P atoms/cm2, = total area integrated from GC-(phosphorus selective detector) chromatogram of the sample wafer for phosphorus compounds only, = total area integrated from GC-(phosphorus selective detector) chromatogram of the blank wafer (see Note 5), = total area integrated from GC-(phosphorus selective detector) chromatogram of the standard peak, = weight of phosphorus standard (TCEP or TBP) injected onto the standard tube, ng, This is a Draft Document of the SEMI International Standards program. No material on this page is to be construed as an official or adopted Standard or Safety Gui deline. Permission is granted to reproduce and/or distribute this document, in whole or in part, only within the scope of SEMI International Standards committee (document development) activity. All other reproduction and/or distribution without the prior written consent of SEMI is prohibited. Page 10 Doc. 5389 SEMI LETTER (YELLOW) BALLOT TC DRAFT Document Number: 5389A Date: 2/12/2016 Semiconductor Equipment and Materials International 3081 Zanker Road San Jose, CA 95134-2127 Phone: 408.943.6900, Fax: 408.943.7943 MWp = molecular weight of phosphorus standard (TCEP=285.49, or TBP=266.3), SW = total area of the wafer sample, cm2, F = conversion factor = (WT WU)/WT, WT = total weight of the wafer, g, and WU = weight of unused part of the wafer, g. As Ab Wc 10 9 1 TMC NA Ac MWc Sw (2) where: TMC = total molecular organic contaminants molecular /cm2, As = total area integrated from GC-MS chromatogram of the sample wafer for carbon compounds, Ab = total area integrated from GC-MS chromatogram of the reference wafer, Ac = total area integrated from GC-MS chromatogram of the standard peak, Wc = weight of C16 or C20 standard injected onto the standard wafer, ng, MWc = molecular weight of C16 = 226.45 or C20 = 282.55 , NA = Avogadro’s constant = 6.02 ×1023 Sw = one surface area of the wafer sample, cm2. 9.1.3 Assuming molecular weight as about 300 and carbon numbers are 16 or 20, total organic carbons are calculated using equations as follows: TC As Ab Wc 109 1 NA Cn Ac MWc Sw (3) where: TC = total organic carbon contaminants , C atoms /cm2, As = total area integrated from GC-MS, chromatogram of the sample wafer for carbon compounds, Ab = total area integrated from GC-MS chromatogram of the reference wafer, Ac = total area integrated from GC-MS chromatogram of the standard peak, Wc = weight of C16 or C20 standard injected onto the standard wafer, ng, MWc = molecular weight of C16 = 226.45 or C20 = 282.55 , This is a Draft Document of the SEMI International Standards program. No material on this page is to be construed as an official or adopted Standard or Safety Gui deline. Permission is granted to reproduce and/or distribute this document, in whole or in part, only within the scope of SEMI International Standards committee (document development) activity. All other reproduction and/or distribution without the prior written consent of SEMI is prohibited. Page 11 Doc. 5389 SEMI LETTER (YELLOW) BALLOT DRAFT Document Number: 5389A Date: 2/12/2016 Semiconductor Equipment and Materials International 3081 Zanker Road San Jose, CA 95134-2127 Phone: 408.943.6900, Fax: 408.943.7943 NA = Avogadro’s constant = 6.02 ×1023 Sw = one surface area of the wafer sample, cm2. Cn = Carbon one surface number area=of16the orwafer 20 sample, cm2. 9.2 Method B 9.2.1 Calculation of Total Organic Contaminants: 9.2.1.1 When AED or FID is used: TC As Ab Wc 10 9 1 6.02 10 23 16 Ac MWc Sw (4) where: TC As Ab Ac Wc MWc Sw = = = = = = = total organic carbon, C atoms/cm2, total area integrated from GC-AED or FID, chromatogram of the sample wafer for carbon compounds, total area integrated from GC-AED or FID chromatogram of the blank wafer (see Note 5), total area integrated from GC-AED or FID chromatogram of the standard peak, weight of C16 standard injected onto the standard wafer, ng, molecular weight of C16 = 226.45, one surface area of the wafer sample, cm2. 9.2.1.2 When MS is used: TO where: TO = As = Ab = Ac = Wc = Sw = As Ab 1 Wc Ac Sw (5) total organic contaminants, ng C16 equivalent/cm2, total area integrated from GC-MS chromatogram of the sample wafer (see Note 6), total area integrated from GC-MS chromatogram of the blank wafer (see Note 5), total area integrated from GC-MS chromatogram of the standard peak, weight of C16 standard injected onto the wafer, ng, one surface area of the wafer sample, cm2. 9.2.2 Calculation of TP: TP 9 As Ab W p 10 1 6.02 10 23 Ap MW p Sw (6) where: = total organophosphorus, P atoms/cm2, = total area integrated from GC-(phosphorus selective detector) chromatogram of the sample wafer for phosphorus compounds only, Ab = total area integrated from GC-(phosphorus selective detector) chromatogram of the blank wafer (see Note 5), Ap = total area integrated from GC-(phosphorus selective detector) chromatogram of the standard peak, Wp = weight of phosphorus standard (TCEP or TBP) injected onto the wafer, ng, MWp = molecular weight of phosphorus standard (TCEP=285.49 or TBP=266.3), TP As This is a Draft Document of the SEMI International Standards program. No material on this page is to be construed as an official or adopted Standard or Safety Gui deline. Permission is granted to reproduce and/or distribute this document, in whole or in part, only within the scope of SEMI International Standards committee (document development) activity. All other reproduction and/or distribution without the prior written consent of SEMI is prohibited. Page 12 Doc. 5389 SEMI LETTER (YELLOW) BALLOT DRAFT Document Number: 5389A Date: 2/12/2016 Semiconductor Equipment and Materials International 3081 Zanker Road San Jose, CA 95134-2127 Phone: 408.943.6900, Fax: 408.943.7943 = area of one surface of the wafer sample, cm2. 10 Report 10.1 Report the following information: 10.1.1 Sample identification, sample size, sample history including how received or packaged if it has been shipped, surface of wafer desorbed (front, back, or both). (Shipping often can add or remove organic compounds). If the wafer is a witness wafer, report how prepared and exposure conditions, location whether horizontal or vertical, time, flow, etc. 10.1.2 Analysis date, analysis method, wafer desorption time and temperature, purge gas used. Analysis day, method, conditions (time and temperature of desorption, having purge gas or not, etc.) 10.1.3 Manufacturer, types, and models of instruments. The kind and model of the measurement instruments 10.1.4 Identification of operator. 10.1.5 Testing laboratory. Analysis organization. 10.1.6 Software version of instrument. 10.1.7 Analysis results. 10.1.7.1 Total organic contaminants, C atoms/cm2 (when AED or FID is used), or ng C16 equivalent/cm2 (when MS is used). Total organic contaminants concentrations (ng/cm2, molecules/cm2), Chromatograms, etc. 10.1.7.2 Total organophosphorus, P atoms/cm2. 10.1.8 Blank wafer data. The blank wafer should be treated with the same desorption procedure as the sample wafers. Data of reference sample 10.1.9 Calibration data. Data of calibration curve NOTE 1: Reporting of other matters, it is decided by discussing between the related parties. 11 Precision and Bias 11.1 Precision and Bias— The precision of these test methods can be determined from the reproducibility measurement of standards. The accuracy of these test methods can be measured from the recoveries of standards. Calibration curve is made once a week at least. A reference wafer measures it every day. 11.2 Bias — Bias for these test methods has not been determined. 12 Keywords 12.1 atomic emission detector (AED); flame ionization detector (FID); flame photometric detector (FPD); gas chromatography (GC); mass spectrometer (MS); nitrogen/phosphorus thermionic ionization detector (NPD); organic contamination; organophosphorus compounds; phosphorus selective detector; silicon wafer surfaces; thermal desorption NOTICE: Semiconductor Equipment and Materials International (SEMI) makes no warranties or representations as to the suitability of the Standards and Safety Guidelines set forth herein for any particular application. The determination of the suitability of the Standard or Safety Guideline is solely the responsibility of the user. Users are cautioned to refer to manufacturer’s instructions, product labels, product data sheets, and other relevant literature, respecting any materials or equipment mentioned herein. Standards and Safety Guidelines are subject to change without notice. By publication of this Standard or Safety Guideline, SEMI takes no position respecting the validity of any patent rights or copyrights asserted in connection with any items mentioned in this Standard or Safety Guideline. Users of this Standard or Safety Guideline are expressly advised that determination of any such patent rights or copyrights, and the risk of infringement of such rights are entirely their own responsibility. This is a Draft Document of the SEMI International Standards program. No material on this page is to be construed as an official or adopted Standard or Safety Gui deline. Permission is granted to reproduce and/or distribute this document, in whole or in part, only within the scope of SEMI International Standards committee (document development) activity. All other reproduction and/or distribution without the prior written consent of SEMI is prohibited. Page 13 Doc. 5389 SEMI LETTER (YELLOW) BALLOT SW DRAFT Document Number: 5389A Date: 2/12/2016