Chapter5_6

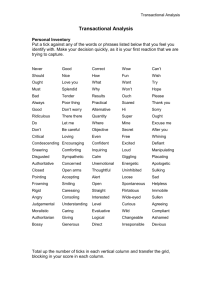

advertisement