Confined Space Management Procedure WHS_P0022 V1

advertisement

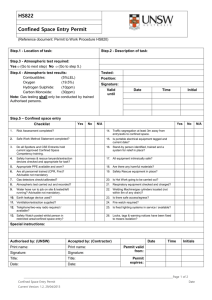

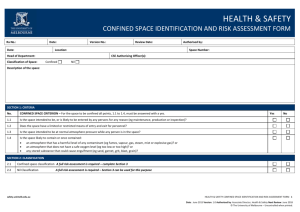

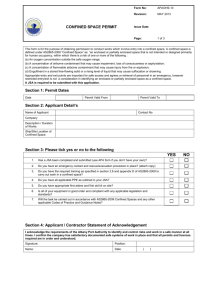

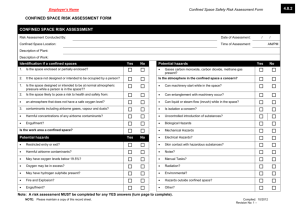

WHS CONFINED SPACE MANAGEMENT PROCEDURE Version No: 1.0 Procedure No. WHS_P0022 Issued: October 2013 Next Review: October 2015 1. Overview 1.1. The Fleurieu Regional Waste Authority (FRWA), as part of its Hazardous Work Policy, recognises its obligation to eliminate, or where that is not reasonably practicable, minimise, risks associated with entering, working in, on or in the vicinity of a confined space. Although FRWA does not have any confined spaces at this point in time, it recognises that this may change in the future and that at times project works on sites may include confined space entry by contractors. 1.2. This procedure aims to: 1.2.1. Assist with the identification of risks to work health and safety (WHS) associated with a confined space. 1.2.2. Provide direction so that legislative compliance related to confined spaces is maintained. 1.2.3. Ensure the provision of relevant information and training. 1.3. Where a PCBU is engaged to work in, on or in the vicinity of a confined space, the person managing the contract should ensure the PCBU is aware of the hazards associated with the confined space and that they have appropriate systems to safely manage confined space work. SIGNED: Executive Officer Worker Representative Date: _____/_____/_____ Date: _____/_____/_____ 2. Core Components 2.1. The core components of our Confined Space Management Procedure aim to ensure: 2.1.1. All confined spaces are identified and documented on the Risk Register. 2.1.2. All entry points to confined spaces are sign-posted and secured against unauthorised entry. 2.1.3. A competent person conducts a risk assessment prior to the first entry into the confined space. 2.1.4. Appropriate controls are identified, implemented and documented. 2.1.5. A confined space entry permit system is in place. 2.1.6. Workers are trained for roles associated with confined space work, in accordance with legislative requirements. 2.1.7. Arrangements for the effective rescue of personnel are in place. 2.1.8. A monitoring process is in place. 2.1.9. Records are established and maintained. 3. Definitions Refer to the Definitions Listing – WHS_FM0001. D:\116100621.doc Electronic version on the Intranet is the controlled version. Printed copies are considered uncontrolled. Before using a printed copy, verify that it is the current version. Page 1 of 13 WHS CONFINED SPACE MANAGEMENT PROCEDURE 4. Version No: 1.0 Procedure No. WHS_P0022 Issued: October 2013 Next Review: October 2015 Procedure 4.1. Design, Manufacture, Supply or Modification to a Confined Space 4.1.1. Management shall ensure that those that design, manufacture, supply, install or construct a plant or structure shall eliminate the need for any person to enter a confined space and the risk of inadvertent entry. If this is not reasonably practicable, then design or procurement documentation should be provided that verifies how the following requirements have been met: a. The need for any person to enter the confined space has been minimised so far as is reasonably practicable; b. The space has be designed with a safe means of entry and exit; and, c. The risk to WHS of those that enter the confined space has been eliminated or, at least, minimised. 4.1.2. Managers with responsibility for overseeing design, manufacture and installation of a plant or structure with a confined space should ensure safety features are incorporated and documentation sought to verify this. a. At the design and manufacturing stage safety features should include: i. The provision of outlets and facilities for cleaning to eliminate the need for entry. ii. The use of lining materials that are durable, require minimal cleaning and do not react with materials contained in the confined space. iii. The provision of safe and easy maintenance to reduce the need for a person to enter the confined space. b. At the design, manufacturing or installation stage safety features should include: i. Access points, including those within the confined space, through divisions, partitions or obstructions, are large enough to allow people wearing personal protective equipment (PPE) to pass through the confined space. ii. A safe means of access to and within the confined space, i.e. fixed ladders, platforms and walkways. iii. Access points are kept clear of fittings or equipment that could impede rescue and able to be kept free of any obstructions during work within the confined space. If electrical cables, leads, hoses and ventilation ducts are required to pass through an access hole a second access point may be needed. iv. Enough access points to provide safe entry to and exit from the confined space, e.g. the spacing of access holes on sewers. In the case of large gas mains, the absence of such access holes over considerable lengths may affect both the degree of natural ventilation and the ease with which workers can be rescued. 4.2. Identification of Confined Spaces 4.2.1. Management should ensure all confined spaces are identified and their location recorded on the Risk Register. 4.2.2. Management should ensure a competent person has identified all confined spaces in consultation with workers and their representatives using the flowchart in Appendix 1. 4.2.3. Management shall maintain the Risk Register and make it available to all workers. D:\116100621.doc Electronic version on the Intranet is the controlled version. Printed copies are considered uncontrolled. Before using a printed copy, verify that it is the current version. Page 2 of 13 WHS CONFINED SPACE MANAGEMENT PROCEDURE Version No: 1.0 Procedure No. WHS_P0022 Issued: October 2013 Next Review: October 2015 4.3. Hazard Identification and Risk Assessment 4.3.1. A risk assessment shall be conducted by a competent person in consultation with workers and their representatives prior to commencing any work that involves entry into a confined space. 4.3.2. The risk assessment should consider the following matters: a. Whether the work can be done without the need to enter the confined space. b. The nature of the confined space. c. The likelihood of changes in the concentration of oxygen or airborne contaminants in the confined space. d. Whether atmospheric testing or monitoring is required and how often. e. The range of, and ultimately proposed, methods by which the work can, or is, carried out. f. The type of emergency procedures required, including rescue procedures. g. Specific hazards associated with confined space entry. h. The competence of those conducting the tasks. 4.3.3. The risk assessment shall be documented and attached to the confined space entry permit. a. A single, or generic, risk assessment may be carried out for a class of confined spaces in a number of different work areas or workplaces where the confined spaces are the same with the same hazards. b. A risk assessment should be carried out on individual confined spaces if there is any likelihood that a worker may be exposed to greater, additional or different risks. c. A safe work instruction (SWI) should be developed for the task being undertaken in the confined space in consultation with workers involved in the task. d. The SWI should result in the: i. Minimisation of the release of harmful airborne contaminants into the space. ii. Reduction in the time spent in the space and the number of people that have to enter the space. iii. Elimination of the risk of engulfment when working in the space. 4.3.4. The person issuing the confined space entry permit should ensure the risk assessment and SWI are explained to those involved in the confined space activity and that the risk assessment is signed by each person before work commences. 4.4. Confined Space Entry Permit 4.4.1. Confined space entry shall be controlled by a permit system. Management should ensure managers do not direct a worker to enter a confined space to carry out work unless a confined space entry permit for the work has been issued. Refer Confined Space Procedure - WHS_P0022. 4.5.1. Managers shall identify those competent to authorise and issue a Confined Space Entry Permit - WHS_FM0016 and they shall also direct and supervise the work. 4.5.2. The confined space entry permit must: a. Be issued by a competent person. b. Be in writing. D:\116100621.doc Electronic version on the Intranet is the controlled version. Printed copies are considered uncontrolled. Before using a printed copy, verify that it is the current version. Page 3 of 13 WHS CONFINED SPACE MANAGEMENT PROCEDURE c. Version No: 1.0 Procedure No. WHS_P0022 Issued: October 2013 Next Review: October 2015 Address all of the specific requirements laid out in the Confined Space Entry Permit - WHS_FM0016. 4.5.3. A Confined Space Entry Permit - WHS_FM0016 must be issued for each entry into the confined space. a. Each permit only applies to one confined space. b. The following documents should be attached to the entry permit, the: i. Completed Confined Space Risk Assessment - WHS_FM0017. ii. SWI for the task. 4.5.4. The person issuing a Confined Space Entry Permit WHS_FM0016 should ensure each worker who is to carry out the work described in the entry permit, is advised of, and understands the contents of the permit. 4.5.5. The Confined Space Entry Permit WHS_FM0016 shall be documented and displayed in a prominent place adjacent to the confined space. It shall detail the name of each worker who enters and exits the space and each worker required for stand-by purposes. 4.5.6. The person issuing the Confined Space Entry Permit - WHS_FM0016 should ensure the risk control measures identified in the risk assessment are listed on the confined space entry permit and are in place before work commences and continue while work is being undertaken. This includes ensuing any plant, equipment, PPE or testing equipment is in good working order. 4.5.7. The Confined Space Entry Permit – WHS_FM0016 should be re-validated if: a. The person with direct control of work in the confined space changes. b. A break in work continuity occurs. c. Changes are made to the work that introduces hazards not addressed by the current permit. d. New control measures are needed. 4.5.8. Any hot work required to be undertaken in or on the exterior surfaces of a confined space shall not commence unless a hot work permit has been issued. 4.5.9. The person issuing the confined space entry permit shall ensure written acknowledgment of the completion of work in the confined space is signed off and all persons involved in the work have left the space at the end of the task. 4.5. Signage 4.5.1. The person issuing the Confined Space Entry Permit – WHS_FM0016 shall ensure that prior to the commencement of work signs are erected to prevent unauthorised entry of persons not involved in the confined space work. The signs must: a. Identify the confined space. b. Inform workers they must not enter the space unless they are nominated on the confined space entry permit. c. Be clear and prominently located next to each entrance to the space. 4.5.2. Signs must be in place while the confined space is accessible, including when preparing to work in the space, during work in the space and when completing work in the space. 4.5.3. Signposting alone should not be relied upon to prevent unauthorised entry to a potential confined space and should be secured against unauthorized entry with locks and fixed barriers. D:\116100621.doc Electronic version on the Intranet is the controlled version. Printed copies are considered uncontrolled. Before using a printed copy, verify that it is the current version. Page 4 of 13 WHS CONFINED SPACE MANAGEMENT PROCEDURE Version No: 1.0 Procedure No. WHS_P0022 Issued: October 2013 Next Review: October 2015 4.6. Communication and Safety Monitoring 4.6.1. A communication system is needed to enable communication between people inside and outside the confined space and to summon help in an emergency. The person issuing the confined space entry permit should ensure that: a. No person enters a confined space unless a worker(s) are on stand-by outside the confined space. b. The standby person is a competent person in relation to confined space entry. c. The standby person is assigned to continuously monitor the conditions within the space, the wellbeing of those inside the space, and, if practicable, observe the work being carried out and initiate emergency procedures when necessary. d. The names of standby persons and their requirements should be recorded on the Confined Space Entry Permit – WHS_FM0016. 4.6.2. The standby person should: a. Understand the nature of the hazards inside the confined space and be able to recognise signs and symptoms that workers may experience when in difficulty. b. Remain outside the confined space and do no other work that may interfere with their primary role of monitoring the workers inside the space. c. Have all required rescue equipment, eg safety harnesses, lifting equipment and lifelines immediately available. d. Have the authority to order workers to exit the space if a hazardous situation arises. e. Never enter the space to attempt a rescue. 4.6.3. The person issuing the Confined Space Entry Permit – WHS_FM0016 should ensure a system for continuous communication between people inside and outside the confined space is in place and it is fully functioning before confined space entry is undertaken. a. Depending on the conditions communication may be via voice, radio, hand signals or other suitable methods. b. The type of communication equipment selected should be recorded on the confined space entry permit. 4.7. Risk Control 4.7.1. Based on the Hierarchy of Control, the risk assessment should indicate what control measures are to be used. Refer to part C of the Confined Space Risk Assessment form – WHS_FM0017. a. Some risk control measures are mandatory for confined spaces. b. In all instances an attempt should be made to eliminate the risk, including the need for persons to enter a confined space. If this not possible, a combination of control measures may be required to effectively manage identified hazards. c. Completed risk assessments shall be available to persons entering confined spaces and other interested parties, e.g. workers, their representatives and other PCU’s. 4.7.2. Specific Control – connected plant and services a. D:\116100621.doc The person issuing the Confined Space Entry Permit – WHS_FM0016 should ensure all potentially hazardous services have been isolated prior to any person entering the confined space, to prevent: Electronic version on the Intranet is the controlled version. Printed copies are considered uncontrolled. Before using a printed copy, verify that it is the current version. Page 5 of 13 WHS CONFINED SPACE MANAGEMENT PROCEDURE Version No: 1.0 Procedure No. WHS_P0022 Issued: October 2013 Next Review: October 2015 i. The introduction of contaminants, substances or conditions by any plant or services connected to the confined space, including through piping, ducts, vents, drains, conveyors, service pipes and fire protection equipment. ii. The activation or energising of any plant or services connected to, or in, the confined space. iii. The activation of plant or services outside the confined space that could adversely affect the space. iv. The release of any stored, or potential, energy in plant. v. The inadvertent use of electrical equipment. b. The Isolation, Lock Out, Tag Out Procedure – WHS_P0024 should be complied with, when relevant. c. Any risk associated with the above must, so far as is reasonably practicable, be eliminated or t least minimised. 4.7.3. Specific Control – atmosphere a. The person issuing the Confined Space Entry Permit – WHS_FM0016 should ensure the confined space has a safe atmosphere, so far as is reasonably practicable. A safe atmosphere in a confined space is one that: Has a safe oxygen level. Is free of airborne contaminants or, where present, in concentrations below their allowable exposure standard. Has flammable gas or vapour is at concentrations below 5% of its LEL. b. A safe atmosphere can be achieved within the confined space using cleaning, purging and ventilation. c. Only a competent person should carry out air monitoring in a confined space. d. Only a suitable, calibrated gas detector should be used to test the atmosphere for oxygen content, airborne concentration of flammable contaminants and/or airborne concentrations of potentially harmful contaminants, e.g. hydrogen sulphide and carbon monoxide. e. Initial testing should be done from outside the confined space by inserting a sample probe and/or portable gas detection device at appropriately selected access holes, nozzles and openings. Because contaminants can settle at different levels each part of the confined space should be tested, side to side and top to bottom. f. The confined space must be purged when a risk assessment identifies the potential for the confined space to contain an unacceptable level of contaminants. g. Ventilation of a confined space with fresh air, by natural, forced or mechanical means, may be necessary to establish and maintain a safe atmosphere and temperature for workers in the confined space. h. If it is not reasonably practicable to provide a safe oxygen level, e.g. the oxygen level is less than 19.5% by volume, the person issuing the confined space entry permit must ensure workers carrying out work are provided with air supplied respiratory equipment. i. If atmospheric contaminants cannot be reduced to safe levels the person issuing the confined space entry permit should ensure a worker does not enter a confined space without being fitted with suitable respiratory protective equipment. D:\116100621.doc Electronic version on the Intranet is the controlled version. Printed copies are considered uncontrolled. Before using a printed copy, verify that it is the current version. Page 6 of 13 WHS CONFINED SPACE MANAGEMENT PROCEDURE Version No: 1.0 Procedure No. WHS_P0022 Issued: October 2013 Next Review: October 2015 4.7.4. Respiratory Specific Control – flammable gases and vapours The person issuing the Confined Space Entry Permit – WHS_FM0016 should ensure that while work is being carried out in a confined space the concentration of any flammable gas, vapour or mist in the atmosphere of the space is less than 5% of its LEL. a. i. b. If it is not reasonably practicable to limit the concentration of flammable gas, vapour or mist in the atmosphere to less than 5% and the atmospheric concentration of the flammable gas, vapour or mist in the confined space is: Less than 10% of its LEL, workers must be immediately removed from the space unless a suitably calibrated, continuous-monitoring flammable gas detector is used in the confined space. Greater than 10% of its LEL, workers must be immediately removed from the confined space. An ignition source must not be introduced into a confined space, from outside or within, if there is a possibility of the ignition source causing a fire or explosion in the confined space. 4.7.5. Emergency Procedure a. Management shall ensure that emergency procedures are developed to manage potential emergences in confined spaces, and include: i. First aid and rescue procedures. See Appendix 3 and part D of the Confined Space Risk Assessment Form – WHS_FM0017. ii. Testing them regularly with workers who undertake work in confined spaces. b. Management should make sure that: i. Openings for entry and exit of the confined space are large enough to allow emergency access; the entry and exit openings are not obstructed; and any plant, equipment and PPE provided for first aid or emergency rescue are maintained in good working order. ii. Prior arrangements have been made with emergency services to ensure they are able to respond to confined space emergencies. iii. Any worker required to undertake rescue has been properly trained, is fit to carry out their task and is capable of using any equipment provided for rescue, e.g. breathing apparatus, lifelines and fire-fighting equipment. d. The person issuing the confined space entry permit should record the required emergency response procedures and equipment on the permit. e. The standby person should initiate first aid and rescue procedures from outside the confined space in an emergency, as soon as practicable. f. Air supplied respiratory equipment shall be available and maintained in good working order if workers are required to undertake rescue in the following situations: i. The atmosphere in the confined space does not have a safe oxygen level; or ii. The atmosphere in the space has a harmful concentration of an airborne contaminant. g. D:\116100621.doc If the risk assessment identifies the serious risk of engulfment of the confined space occurring while workers are either in or outside the confined space suitable PPE should be provided. Electronic version on the Intranet is the controlled version. Printed copies are considered uncontrolled. Before using a printed copy, verify that it is the current version. Page 7 of 13 WHS CONFINED SPACE MANAGEMENT PROCEDURE Version No: 1.0 Procedure No. WHS_P0022 Issued: October 2013 Next Review: October 2015 4.8. Work Completed in the Confined Space 4.8.1. The person issuing the Confined Space Entry Permit – WHS_FM0016 shall ensure the permit is signed off upon the completion of the work and that all workers involved have left the confined space. 4.8.2. The person issuing the Confined Space Entry Permit – WHS_FM0016 should ensure permits and associated records are retained 4.9. Accident or Incidents in a Confined Space 4.8.1. In the event of an incident the Incident Reporting and Investigation Procedure – WHS_P0009 shall be followed. 4.9.1. A rescuer or first aid officer shall not put themselves at risk to deliver first aid and should follow the control measures documented in the emergency plan for the confined space. 4.9.2. Any worker suspected of receiving an electrical shock in a confined space should be taken for medical assessment regardless of how well they feel. 4.9.3. Any worker involved in an incident in a confined space shall report the incident to their manager immediately. Managers should immediately notify SafeWork SA or the Office of the Technical Regulator if the incident meets the requirement for Statutory notification, as per the Incident Reporting and Investigation Procedure – WHS_P0009. 4.10. Monitoring and Evaluation 4.10.1. Managers should review and revise any existing risk control measures related to confined spaces: a. When the control measures do not minimise the risk so far as is reasonably practicable. b. Before a change at the workplace that is likely to give rise to a new or different WHS risk that the control measure may not effectively control. c. If a new hazard or risk is identified. d. If the results of consultation indicate that a review is necessary. 4.10.2. Managers should monitor confined space entry by: a. b. Periodically inspecting: i. Confined space documentation, i.e. risk assessments and entry permits, to ensure proper completion. ii. Confined space work to check compliance with documented procedures. Checking training and competency requirements are maintained. 4.10.3. Management should: a. Review confined space hazard and incident statistics, audit results, legislative changes and other information relating to the confined space management procedure and direct action when required. Minutes shall record outcomes of discussion and actions undertaken. b. Include the confined space management procedure as part of the ongoing management review process and include the findings of internal audits into the procedure. c. Set, monitor and review objectives, targets and performance indicators for any confined space management program. D:\116100621.doc Electronic version on the Intranet is the controlled version. Printed copies are considered uncontrolled. Before using a printed copy, verify that it is the current version. Page 8 of 13 WHS CONFINED SPACE MANAGEMENT PROCEDURE Version No: 1.0 Procedure No. WHS_P0022 Issued: October 2013 Next Review: October 2015 5. Training 5.1. The training needs analysis shall identify the training needs for all workers who: 5.1.1. Are required to enter or work in or on a confined space. 5.1.2. Undertake hazard identification and risk assessment in relation to a confined space. 5.1.3. Implement risk control measures. 5.1.4. Issue entry permits. 5.1.5. Act as a standby person to monitor conditions while work is being carried out in a confined space. 5.1.6. Purchase equipment for confined space work. 5.1.7. Design a work area that includes a confined space. 5.1.8. Manage or supervise persons working in or near a confined space. 5.1.9. Purchase, distribute or maintain PPE for use in a confined space. 5.1.10. Could be involved in a rescue or first-aid procedure involving work in a confined space. 5.2. The training should be relevant to the performance of the particular work and the worker’s duties, and relate to the following: 5.2.1. The nature of the hazards relating to confined spaces. 5.2.2. The need and use of control measures. 5.2.3. The selection, fit, use, wearing, testing, storage and maintenance of PPE. 5.2.4. The contents of any confined space entry permit. 5.2.5. Emergency procedures. 5.3. A registered training organisation shall deliver legislatively mandated training. 6. Records 6.1. The following records should be maintained: 6.1.1. Risk Assessments. 6.1.2. Confined Space entry permits. 6.1.3. Training records. 6.1.4. Risk Register. 6.1.5. Plant, equipment and PPE maintenance records. 6.1.6. Registration certification for relevant plant and equipment. 6.1.7. Records of atmospheric testing and monitoring. 6.1.8. Statutory notifications. 6.2. All records should be retained in line with the current version of GDS20. 7. Responsibilities 7.1. Managers are accountable for the actions listed above, and: 7.1.1. Recommending budgetary expenditure necessary to support this procedure. D:\116100621.doc Electronic version on the Intranet is the controlled version. Printed copies are considered uncontrolled. Before using a printed copy, verify that it is the current version. Page 9 of 13 WHS CONFINED SPACE MANAGEMENT PROCEDURE Version No: 1.0 Procedure No. WHS_P0022 Issued: October 2013 Next Review: October 2015 7.1.2. Providing workers with any necessary information, instruction, training and supervision to enable the application of this procedure. 7.1.3. Ensuring there is a competent person to manage the permit system. 7.1.4. Consulting with other PCBUs, so far as is reasonably practicable, if their duty of care overlaps. 7.2. Workers are accountable for the actions listed above: 7.2.1. Attending training when required. 7.2.2. Complying with the requirements of the risk assessment, confined space entry permit and all relevant WHS policies and procedures, information and instruction provided to them whilst undertaking their tasks. 7.2.3. Taking reasonable care of their own health and safety and that their work does not adversely affect the health and safety of other persons. 7.2.4. Reporting any hazardous situations or confined space problems immediately to their manager. 8. Review 8.1. This procedure should be reviewed by management in consultation with workers every 2 years, or earlier if one or more of the following necessitates change: 8.1.1. Legislative compliance issues. 8.1.2. Audit findings relating to confined space tasks. 8.1.3. Incident and hazard reports related to confined space tasks, claims costs and trends. 8.1.4. Feedback from managers, workers, contractors or other stakeholders. 8.1.5. Other relevant information. 8.2. Results of reviews may result in preventative and/or corrective actions being implemented and revision of this document. 9. References South Australian Work Health and Safety Act (SA) 2012 South Australian Work Health and Safety Regulations (SA) 2012 General Disposal Schedule 20 for Local Government WorkCoverSA Performance Standards for Self-Insurers 10. Related Documents LGA WHS and Injury Management Policy LGA Workplace Injury Management Procedure Definition Listing – WHS_FM0001 Hazardous Work Policy -WHS_P0003 Communication and Consultation Policy – WHS_P0001 Hazardous Management Policy - WHS_P0002 Administration Policy – WHS_P0004 Emergency Management Policy – WHS_P0005 D:\116100621.doc Electronic version on the Intranet is the controlled version. Printed copies are considered uncontrolled. Before using a printed copy, verify that it is the current version. Page 10 of 13 WHS CONFINED SPACE MANAGEMENT PROCEDURE Version No: 1.0 Procedure No. WHS_P0022 Issued: October 2013 Next Review: October 2015 Hazard Management Procedure - WHS_P0010 Contractor Management Policy – WHS_P0006 Contractor Management Procedure - WHS_P0017 Emergency Management Procedure - WHS_P0026 First Aid Procedure - WHS_P0018 Electrical Safety Procedure - WHS_P0021 Isolation and Lock Out Tag Out Procedure – WHS_P0024 Plant Procedure – WHS_P0014 Hazardous Chemicals Procedure – WHS_P0020 Prevention of Falls Procedure – WHS_P0025 Incident Reporting and Investigation Procedure – WHS_P0009 Induction and Training Procedure – WHS_P0007 Corrective and Preventative Actions Procedure – WHS_P0011 Consultation and Communication Procedure – WHS_P0016 Confined Space Risk Assessment Form – WHS_FM0017 Confined Space Entry Permit Form – WHS_FM0016 Consultation Record – WHS_FM0006 Confined Space Register Risk Register SWP’s Document History: D:\116100621.doc Version No: Issue Date: 1.0 Oct 2013 Description of Change: New Document Electronic version on the Intranet is the controlled version. Printed copies are considered uncontrolled. Before using a printed copy, verify that it is the current version. Page 11 of 13 WHS CONFINED SPACE MANAGEMENT PROCEDURE Version No: 1.0 Procedure No. WHS_P0022 Issued: October 2013 Next Review: October 2015 APPENDIX 1: Confined space identification Source: Code of Practice – Confined Spaces December 2011, pp D:\116100621.doc Electronic version on the Intranet is the controlled version. Printed copies are considered uncontrolled. Before using a printed copy, verify that it is the current version. Page 12 of 13 WHS CONFINED SPACE MANAGEMENT PROCEDURE Version No: 1.0 Procedure No. WHS_P0022 Issued: October 2013 Next Review: October 2015 Appendix 2: Information only – summary of procedures for entry and conduct of tasks in a confined space. Note: the diagram refers to clauses outlined in Australian Standard AS 2865: Confined spaces 2009. This information should be checked against the requirements of this procedure and current WHS legislation D:\116100621.doc Electronic version on the Intranet is the controlled version. Printed copies are considered uncontrolled. Before using a printed copy, verify that it is the current version. Page 13 of 13