Oxidation of Silicon

advertisement

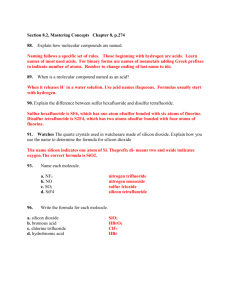

Oxidation of Silicon Objective: This experiment will demonstrate thin film formation through oxidation of silicon to form a SiO2 thin film on silicon. Theory: The oxidation of silicon is a diffusion process as follows: Due to the relatively open structure of SiO2, oxygen molecules or water molecules will diffuse through the growing SiO2 layer and reach the silicon surface, whereupon these molecules will form SiO2. Under exposure to oxygen (1), a silicon surface oxidizes to form silicon dioxide (SiO2). Native silicon dioxide is a high-quality electrical insulator and can be used as a barrier material during impurity implants or diffusion, for electrical isolation of semiconductor devices, as a component in MOS transistors, or as an interlayer dielectric in multilevel metallization structures such as multichip modules. The ability to form a native oxide was one of the primary processing considerations which led to silicon becoming the dominant semiconductor material used in integrated circuits today. Thermal oxidation of silicon is easily achieved by heating the substrate to temperatures typically in the range of 900-1200 degrees C. The atmosphere in the furnace where oxidation takes place can either contain pure oxygen or water vapor. Both of these molecules diffuse easily through the growing SiO2 layer at these high temperatures. Oxygen arriving at the silicon surface can then combine with silicon to form silicon dioxide. The chemical reactions that take place are either for so-called "Dry Oxidation" or "Wet Oxidation". Thickness Determination: Light reflected from the surface of an oxidized Si wafer will experience constructive interference when the path length in the oxide is equal to an integer multiple of the wavelength of the light. 2X0 = Kλ/n Where X0 – Oxide thickness, K= 1,2,.. Wavelength of the incident light and ‘n’ is the refractive index (1.46) for SiO2 Color Chart Growth Rate Chart ELECTROMAGNETIC SPECTRUM