APPLICATION OF NMR-IMAGING FOR ANALYSIS OF MASS

advertisement

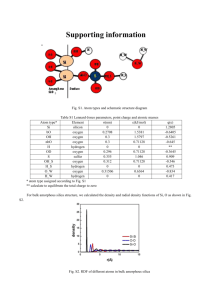

DYNAMICS OF WATER SORPTION ON COMPOSITES “CaCl2 IN SILICA”: SINGLE GRAIN, GRANULATED BED, CONSOLIDATED LAYER YU.I.ARISTOV, I.S.GLAZNEV, L.G.GORDEEVA Boreskov Institute of Catalysis, Pr.Lavrentieva 5, Novosibirsk, 630090 Russia I.V.KOPTYUG, L.YU.ILYINA International Tomography Centre, Institutskaya 3a, Novosibirsk, 630090 Russia J.KÄRGER, C.KRAUSE University of Leipzig, Linnéstraße 5, D-04103 Leipzig, Germany B.DAWOUD Aachen University (RWTH–Aachen), Schinkelstrasse 8, D-52062 Aachen, Germany 1. Introduction Development and study of novel nanoporous adsorbents is a very challenging goal of current material science research. Among these materials are new alumosilicates, alumo- and iron phosphates, MCMs, SBAs, MOFs, carbon sieves, etc., with the pore size of few nanometers. Less progress is made in developing new adsorbents with relatively large pores of 7-20 nm. The idea to modify a common mesoporous adsorbent (silica, alumina, etc.) by introducing inside its pores a hygroscopic salt (CaCl2, LiBr, etc.) was known at least since 1929 [1]. Such materials were used as adsorbents in gas masks and then were almost forgotten. New impact has recently been done in a set of papers [2-6] which presented the result of systematic study of adsorption and thermophysical properties of a family of composite materials “salt inside porous host matrix” which were called “Selective Water Sorbents” (SWSs). Some of the SWSs synthesised and studied are displayed in Table 1. Despite of the short renaissance period these materials have already met practical applications as gas drying agents and materials for active heat insulation in aerocraft “black boxes”. For these and other possible applications that are under development now (freonless solar driven chillers [7] and fresh water production from the atmosphere [8]) the dynamics of water sorption is of high interest. 2 Here we present the first results on kinetics of water sorption on composite “CaCl2 in mesoporous silica KSK” (SWS-1L) that at the moment is the most studied material of SWS-type [3,5]. Here we focus mainly on the dynamics of water adsorption under vacuum conditions when water vapour is the only component in the gas phase although few results are reported on water adsorption from air flux as it takes place in air drying units. Three adsorbent configurations will be considered, namely, a single grain, a granulated layer and a consolidated layer prepared with a binder and pore-forming additives. Three methods have been used to study the water transport and sorption: a) 1H NMR microimaging experiments on the spatial distribution of sorbed water in the sorbent and its temporal evolution, b) the PFG NMR method and c) the kinetics of water sorption under constant volume-variable pressure conditions. The first method is a direct one because it directly measures water concentration profiles and can give the water transport diffusivity. The second method is used for measuring water self-diffusivity, and the last one, in principle, allows to estimate the water diffusivity from the uptake curves [9]. TABLE I. A list of some SWS materials synthesised and studied so far Host Water sorption, matrix g/g Silica gel KSK 0.65 Silica gel KSM 0.25 aerogels 1.0-1.50 Carbon Sibunit 0.57 Al2O3 0.52 Silica gel KSK 0.67 Silica gel KSM 0.25 Carbon Sibunit 0.60 Al2O3 0.55 Silica gel KSK 0.60 Remarks SWS-1L SWS-1S SWS-1Aero SWS-1C SWS-1A SWS-2L SWS-2S SWS-2C SWS-2A SWS-3L [3] [4] [5] [5] [5] [6] [6] [6] [6] [6] LiCl Silica gel KSK 0.60 SWS-4L [6] MgSO4 Silica gel KSK Al2O3 0.65 0.50 SWS-5L SWS-5A [5] NaSO4 Silica gel KSK 0.62 SWS-6L [5] CuSO4 Silica gel KSK 0.58 SWS-7L [5] Salt CaCl2 LiBr MgCl2 Reference 3 2. Experimental 1 H NMR microimaging experiments were performed at 300 MHz on an Avance NMR spectrometer equipped with a microimaging accessory. A sample was placed in the rf coil of the NMR probe with its axis oriented along the magnetic field of the superconducting magnet, pumped down and connected to an evaporator to maintain a fixed vapour pressure over the sample during the water sorption process. More details can be found in [10,11]. The sample was either a single cylindrical grain (diameter 6 mm, length 6 mm) or a bed of spherical grains 2-3 and 5-6 mm in diameter. The bed diameter was 25 mm, the length was 30 mm. The pellets of the commercial silica KSK (the average pore diameter 15 nm, the specific surface 350 m2/g, the pore volume 1 cm3/g) were impregnated with a 38 wt.% CaCl2 aqueous solution and then dried at 1500C. Consolidated SWS layers were prepared using silica (KSK, Davisil 60 and Davisil 150) or alumina A1 powder together with a binder (pseudoboehmite). In order to analyse the relative importance of the diffusional resistance in macropores between the adsorbent particles and in mesopores inside the particles, we varied the size of powder particles (between 0.04 and 0.5 mm), the size of mesopores (between 6 and 15 nm) and the amount of the binder (0-30 wt.%). A carbon Sibunit and an ammonia bicarbonate were used as poreforming additives. The silica gels and alumina were moulded with the binder as a cylindrical tablet of 16 mm diameter and 4-8 mm thickness and then impregnated with aqueous solution of CaCl2. Porous structure of the tablets was determined by SEM, BET and mercury porosimetry. The sample holder allows the water adsorption only through the upper flat surface of the tablet. The PFG NMR experiments were performed using the home-built PFG NMR spectrometer FEGRIS 400 NT operating at a 1H resonance frequency of 400 MHz [12]. The probe head equipment allows measurements at temperatures from ~120 to 470 K (1H NMR resonance) and gradients up to 35 Tm-1. The procedure of the kinetic measurement under constant volume-variable pressure conditions is described elsewhere [13. 3. Results and discussion 3.1. SINGLE GRAIN First experiments with a single SWS-1L grain were performed under the flow regime when the dry cylindrical grain (radius R = 3 mm) was placed in a flux of humid air [10]. 1D profiles of adsorbed water are presented in Fig. 2a. Sharp front of water adsorption is observed. The front propagates inside the grain 4 with a constant rate (shrinkage cylinder behaviour) so that the calculated uptake is mt/m = (2/R) t – (/R)2 t2 and the rate of adsorption decreases with the sorption time as (2/R) – 2(/R)2 t. This decrease is in line with our experimental data on water breakthrough curves in a plug flow adsorber with SWS-1L. b tim e a -0.4 -0.2 0.0 0.2 0.4 distance, cm Figure 2. Visualization of the dynamics of the water sorption by a cylindrical SWS-1L grain. Air flow FL=390 l/h, relative air humidity RH=55%. a) 2D SPI images; accumulation time per image was 13 min 39 s; b) 1D profiles of water content along the diameter of the pellet, accumulation of each profile lasted 34 s, every 8 th profile is shown. The overall time span of the experiment was 290 min. [10]. The physical reason of the rate decreasing could be a mass transfer resistance in the liquid layer near the external surface of the grain (Fig. 2b). Indeed, the surface transfer coefficient ks depends on the layer thickness and the mass transfer surface area S = 2 (R – ) L (where L is the grain length) and can be defined as ks = Dl S/, where Dl is the water diffusivity in the liquid layer. This coefficient decreases during the water sorption due to gradual reduction of S with simultaneous raise of (Fig. 2b). This model could explain the observed effect only if the water diffusivity in the liquid phase (Dl) is lower than in the gas phase (Dg). Indeed, for molecular diffusion in large transport pores of silica the water diffusivity in air at P=1 atm equals Dg = 0.23 cm2/s while in a 3M CaCl2 aqueous solution Dl = 1.2710-5 cm2/s. Such low gas diffusivities are observed in small silica pores of 60 nm size where the Knudsen regime takes place. In general case, the diffusion through both gas and liquid phase can take place and for these parallel routes the effective diffusivity D eff can be 5 calculated as 1/Deff = xl /(l Dl) + xg /(g Dg), where xl and xg are the pore volume fractions occupied by the liquid and gas phase, respectively (xl + xg = 1); l and g are the tortuosity factors for these phases. Thus, to analyse the water transport in SWS-composites at least two new effects should be taken into considered, namely, a) the surface resistance due to formation of the solutions liquid layer near the grain external surface, and b) the complex water diffusivity both through gas and liquid phase in this layer. This pattern is formally similar to the case of the gas and surface diffusion but it is more general as the surface diffusion occurs along the geometrical surface (that means mainly within the first monolayer, xl << 1) while for SWS materials the pores can be completely filled with liquid solution (xl = 1) even at relative humidity 40-70% << 100% (conventional condensation). Considering a non-condensable gas in such wet porous media, the gas phase diffusion should strongly depend on the configuration of free pore space available for gas diffusion that is varied due to water adsorption. The liquid diffusion is a function of the gas solubility, its diffusivity, the tortuosity of the layer, etc. This class of problems is quite different from those typical for microporous solids (hindered diffusion, single-file diffusion, etc.). In the case of single component (water) diffusion the water concentration profiles measured by 1H NMR microimaging technique for a single pellet of the CaCl2/ (silica KSK) are presented in Fig. 3 at time moments t = n t0, where t0 = 9 min. 40 s, n = 0 - 28. At water uptake w > 0.1 g/g the NMR signal is proportional to the average concentration of sorbed water. The adsorption front was found to reach the centre of the pellet approximately after 35-45 min (Fig. 3). The effective water diffusivity D can be estimated from the temporal evolution of water concentration profiles. If we assume that the sorbent pellet is isothermal and the pellet length is infinite, the water transport can be described by 1 rD t r r r , where is the water uptake in the sample, r is the radial co-ordinate. To obtain the mass diffusivity from the experimental water concentration profiles this equation can be integrated with respect to r 1 D r r 0 r r r r dr . t 6 The thus calculated diffusivity is presented against the sorbed water uptake in Fig. 4. Despite of the boundary effects, this procedure allows an estimation of the effective water diffusivity in a single SWS-1L pellet equal to (2.0 1.0)106 cm2/s at water uptakes w = 0.05-0.3 g/g which is close to the values of the self-diffusivity Dself obtained by the PFG NMR (Fig. 4). For the KSK silica fully saturated with a 40 wt.% CaCl2 solution this method gives for solution in pores Dpself = 7.310-6 cm2/s. This value for the bulk solution can be estimated by the extrapolation of the literature data to high salt concentration Dbself = 1.210-5 cm2/s. For solution filled pores the equation Dpself = Dbself / is valid (where is the porosity of silica KSK single grain ( = 0.726) and is the tortuosity of the silica pore). The empirical parameter can be estimated from the last equation = 1.19. Thus, this approach gives very convenient tool to measure the tortuosity factor. distance, cm Figure 3. 1D water concentration profiles inside a single grain of the SWS-1L measured every 9 min 40 s [11]. The sorbent temperature was 21oC, the pressure of water vapour was 17.5 mbar. Figure 4. Effective water diffusivity in SWS-1L single grain as a function of the moisture uptake calculated from the concentration profiles () (see Fig. 3) together with the data on the water selfdiffusivity measured by a PFG NMR (). 3.2. PELLETIZED BED The study of the water transport in a pelletised bed is obviously restricted to model beds of small size (approximately 25-30 mm) close to the size of the NMR measuring cell. Typical water concentration profiles inside the SWS-1L bed were found to be strongly dependent on the pellet size (Fig. 5, a,b). 7 For the small (2-3 mm) pellets the formation of the adsorption front is observed (Fig.5, a) that indicates the regime of the bed diffusion control. The other extreme mode is realised for the bed of the large (5-6 mm) pellets where the sorption is almost homogeneous in space (Fig.5, b). In this case the vapour easily penetrates the bed so that its pressure is constant along the bed, hence, the rate of the sorption is defined by the diffusion inside single pellets (the intraparticle diffusion control). Indeed, it was demonstrated that the kinetics of water adsorption (obtained by integrating the water concentration profiles) for the single SWS-1L grain and the bed of such grains almost coincide [11]. a) b) distance, cm Figure 5. Typical water concentration profiles inside the SWS-1L bed consisted of the pellets of 2-3 (a) and 5-6 (b) mm size [11]. Vapour pressure 17.5 mbar. The crossover between the bed and the pellet diffusion control depends on the ratio of the diffusional time constants A= (Dlayer/L2)/ (Dpellet/R2)], where Dlayer and Dpellet are the effective water diffusivities in the layer and in the pellet, L is the layer thickness, R is the pellet radius [9]. Assuming that the cross-over takes place at A 1, the effective water diffusivity in the layer can be estimated as Dlayer = (Dpellet) (L/R)2 (48) 10-4 cm2/s. This diffusivity can be considered as an effective diffusivity D layer Dlm /(1 - )K, where is the layer porosity ( 0.4), Dlm is the molecular water diffusivity in the layer and K is the water sorption equilibrium constant (for linear systems w = K C, where C is the water concentration in the gas phase). The Dlm can be written as Dlm = Dm / , where Dm is the molecular diffusivity of water at 17.5 mbar (Dm = 13.1 cm2/s). Assuming 1.0-1.5 and calculating K = 2.5 104 cm-3/cm-3 from the water sorption isotherm, one can obtain Dlm = 8.7- 8 13.1 cm2/s and Dlayer (2.33.5) 10-4 cm2/s, that is close to the value estimated from the cross-over point. 3.3. CONSOLIDATED SORBENT LAYER PREPARED WITH THE BINDER Although a pelletised bed can provide sufficient mass transport properties, the heat transfer is strongly restricted by a poor heat conductivity of the layer that is not acceptable, for instance, for adsorption heat pumps. An efficient way to solve this problem is to organise a sorbent as a consolidated layer where primary sorbent particles of the size R are glued with a binder. This can greatly enhance the heat transport properties although the mass transfer is now less efficient, and a reasonable compromise should be reached by varying the primary particle size, the nature and amount of the binder as well as by using special pore forming additives. Following this approach we synthesised various layers (tablets) based on SWS-1L and SWS-1A (see Experimental) and studied the water adsorption in and transport through these layers by means of the NMR microimaging. The typical water distribution profiles in SWS-1L layers are presented in Fig. 6. The sole difference between the two samples was the diameter of mesopores inside the primary silica particles that was either 6 or 15 nm. Fig 6 shows that neither the profile shape nor the profile dynamics are influenced by this size. Thus, the mass resistance in mesopores can be neglected and bed diffusion controls the total sorption rate. thickness - 7 mm. Vapour comes from the left. 10 8 8 6 6 4 2 4 0 0.0 0.2 0.4 0.6 0.8 2 distance, cm 0 Figure 6. Water distribution profiles in the SWS-1L layers with various mesopores, measured at time 11 min (,); 1 h 37 min (,); 3 h 4 min (,); 13 h 11 min (,) and 17 h 30 min (,) [11]. Mesopore diameter is 6 nm (open symbols) and 15 nm (solid symbols). Binder content is 30 wt.%. Vapour pressure – 6.5 mbar, sample 0 2 4 6 8 distance, mm Figure 7: Water concentration profiles in the SWS-1L layers measured at time 11 min (); 1 h 37 min () and 5 h 57 min () [11]. Open symbols - binder content 20 wt.%, fraction 0.15-0.25 mm; solid symbols - binder content 30 9 wt.%, fraction 0.15-0.25 mm; other symbols - binder content 20 wt.%, fraction 0.04-0.06 mm. Vapour pressure - 6.5 mbar. The mesopore diameter is 15 nm. silica Fig. 7 demonstrates the faster diffusion in the layer consisting of the larger SWS particles (0.15 - 0.25 mm compared to 0.04 - 0.06 mm) because of the larger interparticle voids available for vapour transport. When the amount of the binder is increased, the voids are getting smaller, hence, it takes a longer time for the water sorption front to propagate inside the layer (Fig. 7). Thus, it is profitable to decrease the binder content, at least until the layer thermal conductivity and mechanical strength still remain acceptable. The use of poreforming reagents can also lead to the increase in the size of transport pores that facilitates the mass transport but with some sacrifice in other two characteristics [11]. The mechanical strength of SWS-1A layers is much higher than that for SWS1L. This allows a decrease in the binder content down to 2-5 wt.% and a regulation of the pore structure in a wider range. Again, the water adsorption becomes faster if the amount of the binder B decreases (Fig. 8). Moreover, the crossover between the intraparticle diffusion (at B = 20.0 wt.%) and the interparticle (or bed) diffusion (at B = 2.5 wt.%) is clearly observed (Fig. 8). For interparticle diffusion control the value of the effective water diffusivity can be obtained from the shape of the water concentration profiles by means of the Matano-Boltzmann approach [14]. If in the equation for isothermal diffusion in a flat geometry w w , D t x x (w is the water uptake in the sample, x is the co-ordinate perpendicular to the layer surface) substitute t by = x·t-0.5, all the profiles at t > 183 min. almost coincide to give a “universal diffusion profile” (Fig.9). To obtain the mass diffusivity from the measured water concentration profiles this equation can be integrated with respect to x, yielding w Deff 0.5 1 dw dw 0 d w The thus calculated diffusivity is presented against the sorbed water uptake in Fig. 10. The effective water diffusivity shows the tendency to increase from 0.510-6 cm2/s to 3.410-6 cm2/s during water adsorption, which is in agreement with the increase of the water self-diffusivity measured by PFG NMR. 10 4. Kinetics of water sorption at constant volume-variable pressure conditions The kinetics of water sorption on SWS-1L loose grains on an isothermal plate (at T = 50oC) has been measured over a water uptake range 0 – 0.4 g/g. Data obtained for various grain sizes, namely, 0.34-0.5; 0.71-1.0; 1.3-1.6, 3.0-3.2 mm, and various salt contents (0 – 33.6 wt.%) will be published elsewhere. Here we mainly focus our attention on the kinetics of water sorption on SWS1L(33.6 wt.%) at low water uptake where the formation of CaCl2 hydrates takes place. The adsorption kinetic curves are found to be non-exponential with an exponential tail so that (1 – mt/m) ~ exp(-Kt) at long times t (Fig. 11). To describe the rate of water sorption we use the characteristic time of this exponential ( = 1/K) as well as the times 0.5 and 0.9 that correspond to the dimensionless water loadings of 0.5 and 0.9, respectively. All these times are presented in Fig 12 at various water loadings which correspond to appropriate points 1-11 of the water sorption isotherm. The slowest transformation is observed when the formation of the salt dihydrate CaCl2 2H2O takes place CaCl2 + 2H2O CaCl2 2H2O. 6 Figure 8. Water concentration profiles in the SWS-1A layers with various binder content B from 2.5 to 20 wt.%. The profiles are measured every 86 min. The first one was measured at time 11 min. Primary particle size is 0.25-0.5 mm. Vapour pressure is 7.2 mbar. 4 uptake mol/mol 2 0 6 4 2 0 6 4 2 0 0 2 4 Distance , mm 6 11 -5.0 -5.5 2 Log D , sm / s Water content , g/g 0.2 0.1 0.0 0.000 0.002 -6.0 -6.5 0.00 0.004 0.05 0.10 0.15 0.20 uptake g/g sm s-0.5 Figure 10. Effective water diffusivity in SWS-1A layer (20 wt. of binder) against the moisture uptake calculated from the “universal diffusion profile” (Fig. 9). Vapour pressure 7.2 mbar. Figure 9. Water sorption profiles presented as a function of . SWS-1A layer with 20 wt. of binder. Profiles at 3 h 03 min. < t < 7 h 20 min. are treated. () - “universal diffusion profile”.Vapour pressure – 7.2 mbar. A similar dependence (w) is observed for the desorption run which does not coincide with the adsorption one (Fig. 12). Thus, one more inportant feature of the materials “salt inside porous matrix” is a slow chemical transformation due to hydrate formation inside the pores, so that the diffusion with slow reaction and hysteresis has to be considered. The effective water diffusivity estimated from these data is changed from 4.210-11 m2/s to 1.810-10 m2/s for w = 0 – 0.11 g/g and from 8.710-11 m2/s to 5.610-10 m2/s at w = 0.11 – 0.47 g/g. 0 2 0.5 10 12 0.14 6000 5000 0.3 0.2 9 5 3 5 10 0.06 2400 3600 4800 6000 7200 Time [s] Figure 11. Kinetic curves of water sorption on SWS-1L (33.6 wt.%). Curve numbers correspond to appropriate points of the water sorption isotherm (see Fig. 12). 0.04 3 1000 1200 6 4 2000 0 0.08 7 3000 0.1 10 8 4000 1 0.1 0.09 0.08 0.07 0.06 0.12 11 6 Time [s] 1 - mt / m 8 Adsorption Isotherm, 50 oC Desorption Isotherm, 50 oC =1/K 0.5 0.9 0.4 0.05 Pressure [mbar] 6 4 7000 1 0.02 2 0 0 Water Uptake [g/g] 1 0.9 0.8 0.7 0.6 0.02 0.04 0.06 0.08 Water Uptake [g/g] 0.1 0 0.12 Figure 12. Characteristic sorption times for SWS-1L (33.6 wt.% ) as a function of the water uptake as well as the water sorption and desorption isotherms(bold symbols). 12 Acknowledgments. The authors thank the Russian Foundation for Basic Researches (projects N 02-03-32304 and 02-03-32770), the Integration Grant Program of the SB RAS (project N 166) and the NATO (grant PST.CLG.979051) for partial financial support of this work. 13 References 1. US Patent N 1,740,351. (1929) Dehydrating substance, H.Isobe, Dec. 17. 2. Levitskii E.A., Aristov Yu. I., Tokarev M.M., Parmon V.N. (1996) Sol. Energy Mater. Sol. Cells 44, N 3, pp.219-235. c. References 3. Aristov Yu.I., Tokarev M.M., Cacciola G., Restuccia G. (1996) Selective water sorbents for multiple applications: 1. CaCl2 confined in mesopores of the silica gel: sorption properties, React.Kinet.Cat.Lett. 59, N 2, pp.325334. 4. Aristov Yu.I., Tokarev M.M., Cacciola G., Restuccia G. (1996) Selective water sorbents for multiple applications: 2. CaCl2 confined in micropores of the silica gel: sorption properties, React.Kinet.Cat.Lett. 59, N 2, pp.335342. 5. Aristov Yu.I. (2003) Thermochemical energy storage: new processes and materials, Doctoral Thesis, Boreskov Institute of Catalysis, Novosibirsk, 375p. 6. Gordeeva L.G., (2000) New materials for thermochemical energy storage, Ph.D. thesis, Boreskov Institute of Catalysis, 146p. 7. Aristov Yu.I., Restuccia G., Cacciola G., Parmon V.N. (2002) A family of new working materials for solid sorption air conditioning systems, Appl.Therm.Engn. 22, N 2, pp.191-204. 8. Aristov Yu.I., Tokarev M.M., Gordeeva L.G., Snitnikov V.N., Parmon V.N. (1999) New composite sorbents for solar-driven technology of fresh water production from the atmosphere, Solar Energy 66, N 2, pp 165-168. 9. Kaerger J., Ruthven D.M. (1992) Diffusion in Zeolites and Other Microporous Solids, Wiley, N.Y. 10. Koptyug I.V., Khitrina L.Yu., Aristov Yu.I., Tokarev M.M., Iskakov K.T., Parmon V.N., Sagdeev R.Z. (2000) 1H NMR microimaging study of water vapor sorption by individual porous pellets, J.Phys.Chem. 104, pp.16951700. 11. Aristov Yu.I., Koptyug I.V., Glaznev I.S., Gordeeva L.G., Tokarev M.M., Ilyina L.Yu. (2002) 1H NMR microimaging for studying the water transport in an adsorption heat pump // Proc. Int.Conf.Sorption Heat Pumps, Sept. 23-27 Shanghai, China, pp.619-624. 12. Galvosas P., Stallmach F., Seiffert G., Kärger J., Kaess U., Majer G. (2001) Generation and Application of Ultra-High-Intensity Magnetic Field Gradient Pulses for NMR Spectroscopy, J. Magn. Reson. 151, pp. 260-268. 13. Dawoud B., Aristov Yu.I. (2003) Experimental study on the kinetics of water vapour sorption on selective water sorbents, silica gel and alumina under typical operating conditions of adsorption heat pumps, Int.J.Heat&Mass Transfer 46, pp. 273-281. 14. Crank J. (1975)The Mathematics of Diffusion, Oxford Univ. Press, pp.230- 14 238