Magnetic Nanowires from DNA

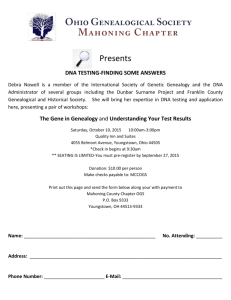

advertisement

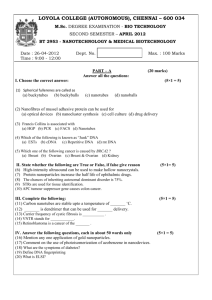

Magnetic Nanowires from DNA William Ballik, Robbie Edwards, Alex Klotz, Gio Mitchell Introduction One of the foremost areas of nano research is into nanowires, nanorods, and nanotubes, the classic example being carbon nanotubes: these nearly one-dimensional structures have one long dimension, perhaps a few microns long and two short dimensions, on the order of nanometers. One relatively unexplored area is magnetic nanotubes, which could be used for applications similar to other magnetic media, such as memory on a very small scale or magnetic field sensors. Of particular interest are magnetic nanotubes where the diameter is less than or equal to the width of the so-called “domain wall” of the materials, a magnetic property of certain metals, which occur at the 10-50 nm thickness scale. There exist fabrication techniques for metallic nanoparticles, involving, for example, electroplating, where an electric current is applied through a solution to cause the deposition of metal particles. Nevertheless, it is extremely difficult to ensure that the width of the material formed remains small, and to control it. This is where biological material comes in: Nature has, of course, had many more years of practice at building small-scale phenomena than Man has. Using existing biomolecules as a type of “backbone” for nanotubes, and in particular magnetic nanotubes, has been done using microtubules and peptides. Still, perhaps the most promising is double-helix DNA, which has several properties that are ideal for nanotubes: a very narrow width (on the order of 2 nm), a very straight line (without any branching into different directions), and an efficient self-assembly mechanism (using base-pairs). It is because of this that Qun Gu, Chuanding Cheng, and Donald T. Haynie of Louisiana Tech University have used DNA to form 10-20 nm high magnetic cobalt-based nanotubes. Figure 1: Atomic Force Microscopy image of DNA on mica substrate. The width of DNA is 1-2 nm; the white line is 1 um. From DNA to Cobalt Nanowire Bacteriophage DNA was used in all experiments; an image of the DNA before nanotube creation is recorded in Figure 1. Two different materials were used as the substrate, or base plate, for the nanotube growth: mica and silated glass (glass with some silicon added). These needed to be prepared in different ways, but both followed a general three-step process. The DNA was first “activated” using palladium ions, which attach to some of the bases in the helix. Then a biochemical called DMAB was used to reduce (de-ionize) the palladium ions on the DNA. And finally, cobalt ions are added in the solution and attach to the DNA with the palladium acting as a catalyst. This process is called electroless as it does not require an external electric potential to operate. The use of the palladium allows for high uniformity of cobalt and a great deal of control over where the cobalt goes: the cobalt will only attach to the parts of DNA coated with palladium. The palladium activation took place over an incubation period of about 24 h at body temperature, and the actual cobalt plating took place over a period of about 10-15 minutes at 50 degrees Celsius. Additionally, control systems were produced of “unactivated” DNA (without the palladium ions added) reacting with palladium and cobalt in solution, as a basis of comparison. Experimental Results The electroless plating led to 10-20 nm high clusters of cobalt on the DNA surface, more or less uniformly distributed along the DNA. An image of the cobalt atoms taken with atomic force microscopy is shown in Figure 2. A second treatment of the DNA in a cobalt bath allowed the nanowires to grow Figure 3. Atomic Force Microscopy characterization of cobalt wires, in the unactivated (A) and activated (B) cases. The vertical scales are 5 and 11nm respectively. even further to 25 nm. Unsurprisingly, the palladium ion-activated DNA fared much better in attaching cobalt clusters (compare the images of figure 3-A and 3-B); the metal coverage was approximately 7080% without the activation, which is not enough to form a continuous nanowire. In order to “straighten out” the cobalt-plated DNA, a so-called “molecular combing” process was used. This process involves one end of the DNA is anchored onto the glass substrate, and then evaporating away the water in the solution so that the other end of the DNA stretches along with the water meniscus. An image of the DNA cobalt nanotubes combing is shown in Figure 4. Figure 4: AFM image of cobalt wires after molecular combint was used to orient them. Conclusions Figure 2: Atomic Force Microscopy characterization of Cobalt wires. The screen area is 1 um x 1 um, and the height is approximately 14 nm. DNA was treated with palladium and coating in cobalt to produce magnetic metallic nanowires. The method was electroless and the wires could be oriented by molecular combing. Metal plating of DNA is a useful technique for creating nanotubes. Before these can be used as memory devices or other applications, directionality has to be controlled, but this represents an important step towards magnetic nanowires. References Gu, Qun; Chuanding Cheng; Donald T. Haynie. “Cobalt metallization of DNA: Towards magnetic nanowires.” Nanotechnology 16 (2005) 1358-1363.