DEPARTMENT OF CHEMISTRY TEACHING LAB EXPERIMENT

advertisement

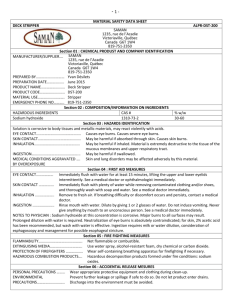

DEPARTMENT OF CHEMISTRY TEACHING LAB EXPERIMENT RISK ASSESSMENT FORM This form must be completed jointly by the Lab Officer in charge and the Lecturer in charge. A hardcopy of the completed form should be kept in a file together with the Project Risk Assessment. Name of Lecturer in Charge Name of Lab Officer in Charge Module / Expt No. A/P Jaenicke Stephan Activity being assessed: Toh Soh Lian CM2167/Expt. 1 Conductivity of Weak & Strong Electrolytes To measure conductivity of ionic solutions of 0.1M NaCl, 0.1M KCl, 0.1M acetic acid, 0.1M HCl, 0.1M NaAc & 0.1M NaOH by using conductivity meter. Known or expected hazards associated with the activity: Hazards of reagents, solvents and known reaction products. State each substance and the approximate amounts to be used/produced. List of activities involved in this experiment which inevitably entail risks. The following are the activities being use: 1) Glass Apparatus. Refer to prepared risk assessment on Use of Glassware. 2) Electricity. Refer to prepared risk assessment on Use of Standard Electrical Equipment. 0.1M Sodium Chloride Solution: about 50ml. No hazardous. 0.1M Potassium Chloride Solution: about 50ml. No hazardous. 0.1M Acetic Acid Solution: about 50ml Irritating to eyes and skin. 0.1M Sodium Acetate Solution: about 50ml No hazardous. 0.1M Hydrochloric Solution: about 50ml. No hazardous. 0.1M Sodium Hydroxide Solution: about 50ml. CAUTION ! Causes respiratory tract, eye and skin irritation and may be harmful if swallowed. Routes of Entry: Dermal contact, eye contact, inhalation, ingestion. *amount stated are computed for the whole experiment. Incompatible materials (special precautions): 0.1M Sodium Chloride Solution Page 1 of 6 Printed on: 12 February 2016 Substances to be avoided: The generally known reaction partners of water. 0.1M Potassium Chloride Solution None, suitable for any general storage. 0.1M Acetic Acid Solution Conditions to Avoid: Heating. Materials To Avoid: Anhydrides/Water; aldehydes, alcohols, halogen compounds, oxidizing agent (i.a. CrO3, Potassium Permanganate, peroxi compounds, Perchloric acid, Chromosulfuric acid), metals, alkali hydroxides, non-metallic halides, ethanolamine. Further information: Incompatible with various metals. 0.1M Sodium Acetate Solution Conditions to Avoid: Heating. Materials To Avoid: Nitrates. 0.1M Hydrochloric Solution: Conditions to Avoid: Heating. Materials To Avoid: Metals (generation of hydrogen). The generally known reaction partners of water. Further information: Unsuitable working materials – metals, metal alloys. 0.1M Sodium Hydroxide Solution: Reactive with metals, acids. Incompatible with organic halogens, nitro and chloro organic compounds, peroxide, Aluminium, Tin, Zinc, strong acids. The risk of injury and its severity likely to arise from these hazards: 0.1M Sodium Chloride Solution: Not available. 0.1M Potassium Chloride Solution: Effects of overexposure: Itching of skin, irritation in an open wound. Irritation of eyes. Ingestion/inhalation: If exposed internally exposure consult physician. 0.1M Acetic Acid Solution Skin & Eye Contact: Irritations. Ingestion: Irritations of mucous membranes in the mouth, pharynx, oesophagus and gastrointestinal tract. Inhalation of vapours: Mucosal irritations 0.1M Sodium Acetate Solution Page 2 of 6 Printed on: 12 February 2016 Skin & Eye Contact: Slight irritations. Ingestion of large amounts:.Gastrointestinal complaints. Inhalation of dust: Slight mucosal irritations. 0.1M Hydrochloric Solution: Skin & Eye Contact: Slight irritations 0.1M Sodium Hydroxide Solution: Skin Contact: Irritant. Skin inflammation is characterized by itching, scaling, reddening, or, occasionally, blistering. Eye Contact: Irritant. Inflammation of the eye is characterized by redness, watering, and itching. Ingestion: May be hazardous in case of ingestion. Inhalation: Hazardous (lung irritant). Aggravated by Overexposure: contact with spray mist may produce chronic eye irritation and severe skin irritation; respiratory tract irritation leading to frequent attacks of bronchial infection. Who is at risk? Persons handling the materials and as well as those present in the vicinity. Measure to be taken to reduce the level of risk: Proper laboratory attire and safety measures must always be used in order to reduce the level or risk. Material should be handled or transferred in an approved fume hood or with adequate ventilation Wash thoroughly after handling. Do not take internally. Eye wash and safety equipment should be readily available. Eye protection: Chemical safety goggles. Hand protection: Gloves. Please refer to PSSO Safety Information Centre website on safety measures: http://www.chemistry.nus.edu.sg/PSSO/Safety.htm. Training prerequisites: This assessment should be read by everyone who will be using the above mentioned chemicals. Please refer to Completed Risk Assessment forms on Common Activities: http://www.chemistry.nus.edu.sg/PSSO/Safety/Risk/risk.htm#Common. Level of risk remaining: Constant vigilance is required by the users. Emergency action if : Spill: 0.1M Sodium Chloride Solution: Do not inhale vapours/aerosols. Do not allow to enter into sink. Take up with liquid-absorbent material. Forward for disposal. Clean up affected area. 0.1M Potassium Chloride Solution: Page 3 of 6 Printed on: 12 February 2016 Clean up and set aside for waste disposal. 0.1M Acetic Acid Solution Do not inhale vapours/aerosols. Avoid substance contact. Ensure supply of fresh air in enclosed rooms. Do not allow to enter sink. Take up with liquid-absorbent material. Forward for disposal. Clean up affected area. Additional notes: Render harmless – neutralize with diluted sodium hydroxide solution. 0.1M Sodium Acetate Solution Avoid generation of dusts; do not inhale dusts. Do not allow to enter sink. Take up dry. Forward for disposal. Clean up affected area. 0.1M Hydrochloric Solution: Do not inhale vapours/aerosols. Avoid substance contact. Do not allow to enter sink. Take up with liquid-absorbent material. Forward for disposal. Clean up affected area. Additional notes: Render harmless – neutralize with diluted sodium hydroxide solution or by throwing on lime, lime sand, or sodium carbonate. 0.1M Sodium Hydroxide Solution: Small Spill and Leak: Dilute with water and mop up, or absorb with an inert dry material and place in an appropriate waste disposal container. Large Spill and Leak: Stop leak if without risk. Absorb with DRY sand or other non-combustible material. Do not touch spilled material. Prevent entry into sink. Call for assistance on disposal. Fire: 0.1M Sodium Chloride Solution: Suitable extinguishing media: In adaption to materials stored in the immediate neighbourhood. Special risks: Non-combustible. 0.1M Potassium Chloride Solution: Extinguishing media: Water, CO2, dry chemical. 0.1M Acetic Acid Solution Suitable extinguishing media: Water, CO2, foam, powder. Special risks: Non-combustible. Development of hazardous combustion gases or vapours possible in the event of fire. The following may develop in event of fire: Acetic acid vapours. Acetic acid vapours: Formation of explosive mixtures possible with air. Other information: Contain escaping vapours with water. 0.1M Sodium Acetate Solution Page 4 of 6 Printed on: 12 February 2016 Suitable extinguishing media: In adaption to material stored in the immediate neighbourhood. Special risks: Non-combustible. Ambient fire may liberate hazardous vapours. The following may develop in event of fire: combustible vapours. 0.1M Hydrochloric Solution: Suitable extinguishing media: In adaption to materials stored in the immediate neighbourhood. Special risks: Non-combustible. Hydrogen may form upon contact with metals (danger of explosion!). Ambient fire may liberate hazardous vapours. The following may develop in event of fire: hydrochloric acid. Other information: Contain escaping vapours with water.. 0.1M Sodium Hydroxide Solution: Fire Fighting Media: Use extinguishing media suitable for surrounding materials. Special Remarks on Explosion Hazards: Can react with certain metals to release explosive hydrogen gas. Is the experiment suitable for out-of-hours operation ? Yes No References if any: http://chemdat.merck.de/cdrl/catalog/standard/en/index.html (Cat. No. : 109945) http://www.phoenixelectrode.com/msds/k00as01.pdf http://chemdat.merck.de/cdrl/catalog/standard/en/index.html (Cat. No. : 109944) http://chemdat.merck.de/cdrl/catalog/standard/en/index.html (Cat. No. : 106265) http://www.emdchemicals.com/analytics/doc/msds/msds-display.asp?materialid=000314 http://www.emdchemicals.com/analytics/doc/msds/msds-display.asp?materialid=SX0607C Signature of Lab Officer in Charge:……………………………………………………………….. Date:………………………… Signature of Lecturer in Charge:………… …………………………………….. Date:… …………………….. Prepared Risks Assessments for standard equipment and operation are with the kind permission of Dr. Ken MacNeil, School of Chemistry, University of Bristol. Page 5 of 6 Printed on: 12 February 2016 Activity being assessed: Note any activity to be used which entail risk (e.g. use of glass vacuum apparatus, high pressures, high voltage, radiation, high temperatures). Give reference to any special protocols to be followed, and if appropriate attach copies to the risk assessment form. State any additional precautions taken to minimise risk. Known or expected hazards associated with the activity: FOR EACH CHEMICAL, read the MSDS and note:a) Particular hazards (e.g. highly toxic, carcinogenic, corrosive, flammable, pyrophoric, explosive, volatile, dust hazard). Note any dangerous combinations of properties (e.g. volatile and toxic). b) Requirements for safe handling (e.g. fume cupboard, inert atmosphere, low temperature). c) How to dispose of residuals Dispose to drain, with water dilution Neutralise, then to drain with suitable dilution To flammable liquid waste receptacle To non-flammable liquid waste receptacle Keep for recovery/recycling Keep for special disposal later (e.g. heavy metals) Double bag and dispose to dry waste Special procedure (specify) Incompatible materials (special precautions) Note any dangerously incompatible materials and hazards arising from contact of any reagents and substances used with common materials such as paper, benches, hoses, etc. Measures to be taken to reduce the level of risk Include hazards of previously unknown products. Location of work – laboratory, open bench, fume cupboard Level of risk remaining: Likelihood and consequences of any accident or unforeseen events whilst carrying out the activity. When this has been done, choose the appropriate procedure:a) Close supervision and/or attendance of trained first-aider needed. b) Specific approval of supervisor needed. c) Training is needed prior-to or during the operations specified. d) Training is complete and only general laboratory competence required. e) No risk perceived. Emergency action: a) Any special requirements to deal with accidental spillage or leakage. b) What to do in the event of accidental exposure (skin contact, inhalation, etc.). Page 6 of 6 Printed on: 12 February 2016