model yd160-1/2

advertisement

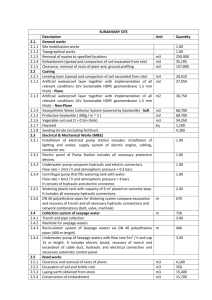

DRILL-QUEST ENGINEERING GMBH MODEL YD160-1/2 HYDRAULIC POWER STATION OPERATION MANUAL . . D R I L L - Q U E S T E N GI N E E R I N G GM B H 1 Summary Model YD160-1/2 hydraulic power station is an independent hydraulic power unit, which is combined by oil pump, control valve, oil tank, electric motor, filter, gauge, etc. The motor of Model YD160-1 is common three-phase motor, not flame-proof type.The motor of Model YD160-2 is flame -p roof fh ree -pha se inductio n mo to r.It is applicable for drilling pipe tong, screwing machine and other hydraulic equipment. This hydraulic power station has many advantages, such as simple configuration, easy operation, sufficient oil supply, high efficiency and stable work property. 2 Technical parameter Max working pressure: 2900 psi (20MPa) Rated flow rate: 2~42 gpm Oil tank volume: 166 gallon Type of the oil pump and motor: 160SCY-YBZ-Y250M-6-37KW Overall dimension: 5.6×4.1×4 ft Weight: 2200 lb Special requirement of power supply:□440V,60Hz□480V,50Hz□660V,60Hz □ 3 Configuration and working principle The schematic diagram of this hydraulic power station is shown in Fig.1. Configuration is shown in Fig.2. The oil pump is a manual variable plunger pump, the oil supply of pump is variable,using the adjust wheel to adjust the out flow of the plunger pump (see Fig.3 and Table 1).The standard motor of the hydraulic power station is Y250M-6-37KW, 380V,50Hz. Fig.1 1 D R I L L - Q U E S T E N GI N E E R I N G GM B H 0 Fig.2 1. JB978-77 pipe joint 2. combination washer22 3.outlet 4.inlet 5.oil tank 6.JB966 pipe joint 14/M18×1.5 7. O ring 16×2.4 8.connection board 9. O ring 20×2.4 10.gauge 0-25MPa 11.gauge joint 12.overflow valve YF-B32H3-S 13. non-return valve 14. pipe joint 15. O ring 42×3.1 16. combination washer 42 17. O ring 65×3.1 18.filter PZU-160×20L-Y 19. air filter EF6-80 20. Temperature meter YWZ-250T 21.globe valve DN50-10 22.nut M60×2 23. O ring 55×3.5 24. elbow piece 50 2 D R I L L - Q U E S T E N GI N E E R I N G GM B H Adjust whe el Graduation Fig.3 Table 1 Graduation of the pluger pump Actual output flow L/min gpm 10 138 36 9 124 33 8 110 29 7 97 26 6 83 22 5 69 18 4 55 15 3 41 11 2 28 7 1 14 4 □Dimension of oil inlet and outlet see Fig.4,the standard is M42×2. □Dimension of oil inlet and outlet:inlet: outlet: 3 D R I L L - Q U E S T E N GI N E E R I N G GM B H oil in le t oil outlet Fig.4 4 Usage, maintenance and attention items 4.1 Adjust the pressure of oil system Adjusting the overflow valve 12 (in Fig.2) to min pressure station,start the motor, adjusting the overflow valve slowly,when the pressure shown in the gauge 10 meet the pressure we needed, then screw down the locknut of the overflow valve .The adjusting range of the overflow valve is 5~20 MPa, the preestablishing pressure in our company is 10 MPa. If the manual is changed or revised later, we have no obligation to notify any person. If the pictures vary from the practicality,please accept the practicality. 4 D R I L L - Q U E S T E N GI N E E R I N G GM B H 4.2 Maintenance and attention items Check carefully the appearance of the hydraulic power station for integrity and damage, check outer parts and accessories and screw on tightly connections loosened during handling and transportation, if any. Choose a spot within l0 meters of the equipment to mount the unit. The spot should be well ventilated. YB-N46 wear-resistant hydraulic oil are The lo wer-limit mark recommended for use in the oil tank. When the ambient temperature is below -25℃, YC-N46 low-freezing hydraulic oil may be a choice. For a short period of time transparent oils of the same grade may be Fig.5 used as a substitute. The temperature of the oil during working is 15~65℃,the correct action must be taken when temperature of oil in the tank is too low or high. Generally, change the hydraulic oil once a year. Protection measures Windo w for wash ing should be taken to prevent moisture or impurities from entering into the oil. When pouring oil into the tank, the lower-limit mark of oil level must be reached (see Fig.5). Check the oil level in the tank regularly and replenish if necessary to reach the upper-limit mark. Clean the oil tank once a year, the window for washing see Fig.6. Fig.6 Don’t run o ver 2900 psi (20MPa), or the power un it will be damaged ! 5, Ordinary trouble and troubleshooting Ordinary trouble Main cause Remedy 5 D R I L L - Q U E S T E N GI N E E R I N G GM B H Insufficient pressure 1, the adjusting value of overflow valve 1, adjusting the overflow valve. is lower. . 2, something is wrong with the overflow 2,.repair the overflow valve. valve. 3, the pressure gauge is aging so as to not 3, inspection and replacing pressure correctly recording the value. gauge. 4, something is wrong in the plunger 4, dismantle the pump and clean every pump. moving part. Then reassembly the worn parts. 1, somewhere of the oil pipe is leaky so 1, fastening adapter, replacing the as to cause insufficient oil supply. sealing piece. 2, shortage of the oil Insufficient 3, . something is dirty between the 2, supply the oil. oil supply distribution oil plate and pump body or 3, dismantle the pump and clean every the retaining pin of the distribution plate moving parts, then reassembly the parts. is not fixed well, as a result the distribution plate is not very well fit. 6 Carry, store , opening the box and after-sales service 6.1 Carry □Handle hydraulic power station steadily and smoothly, keep from getting damp, upside down or damaged. □Keep the hydraulic power station balanced and horizontal not to swing so as to avoid bumping or damaging. 6.2 Store □Store in places free of sunshine, rain and moist, with excellent ventilation and ambient temperature below 45℃. □Don’t leave the hydraulic power station on muddy ground or in the open air □Protect the oil entrance in storage to prevent dirt or dust. □Valid storage time for new hydraulic power station is one year since delivery. Replace part or all of the sealing pieces and hoses after expiration. 6.3 Opening the box □After opening the box, check the appearance of the hydraulic power station, check goods according to the packing list. . .