USE OF THE X-RAY DIFFRACTION UNIT

advertisement

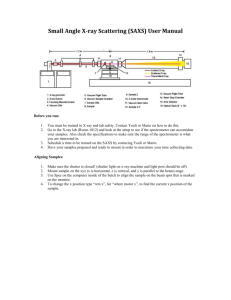

USE OF THE X-RAY DIFFRACTION UNIT FIFTH DRAFT This document outlines the use of the X-ray diffraction (XRD) unit in the Geology Department. The system consists of a Norelco generator, a Philips goniometer, a CrystalLogic interface controlling the goniometer and the acquisition of data, and software obtained from the Chinese Academy of Physics for the processing of the data. The detector for the XRD consists of a NaI iodide crystal coupled to a photomultiplier tube. The arm of the goniometer has a grating that filters out Cu K radiation from the copper tube normally used. It is the user's responsibility to familiarize himself/herself with the contents of this document before using the instrument. Careless errors can damage the instrument but might be hazardous to the user. The X-ray generator is a source of ionizing radiation! SAMPLE PREPARATION Thoroughly grind the sample. The acquisition of accurate intensities from the powder method assumes a random orientation of crystallites. If the well is not ground well and the crystals in the sample are too large, this ideal is not reached. Our present unit does not rotate the sample. The sample can be applied to a special (expensive) Phillip mount, a microscope slide, or a Bakelite cylinder. Chemistry students will use the microscope slide; geologists prefer to use the Bakelite cylinder. Sample Preparation Using a Microscope Slide (Chem 160 Method) In the case of the microscope slide, one could create a glycerine mull of the sample and apply it to a 1” x 3” microscope slide whose length is reduced to yield a slide with the dimensions of 25.4 mm x 46 mm. Uniformly apply the mull over the area 25.4 mm x 30 mm. Other groups have used double sided tape. One side of the tape could be attached to the slide and the pulverized sample could be applied to the adhesive surface. A mull would not be required in this case. In Chemistry 160, we shall employ a third method using a uniformly greased slide. It has given much improved results. The determination of the structure of your compound rests on both the positions and the intensities of the Xray reflections. The analysis of the intensities requires that the crystallites in your sample have random orientations. Results obtained using the method described in the lab manual indicate that this assumption is not satisfied. Presumably, the high pressure in the press partially orients the crystallites. The following method appears to give greatly improved results. 1) Carefully and fully grind the sample in a mortar and pestle. Adding ca. 10-20 ml of acetone to the sample appears to aid the process of pulverizing the sample. 2) Decant off the acetone and allow the sample to dry. 3) The sample may form clumps. Break up the clumps with a spatula or a glass rod. 4) The sample will be mounted on a modified glass microscope slide. A regular microscope slide is cut to yield a slide with dimensions (w x l) of 25.0 mm versus 35.0 mm. a) Uniformly cover 20.0 mm of the length of the slide with a thin film of stopcock grease. A second slide may assist in the application of the layer. b) Gently drop small portions of your powdered sample onto the greased area of the slide. Gently tap the side of the slide to knock off the sample that does not adhere to the grease. c) Repeat step 4c until the slide is uniformly coated with your sample. d) Note that 15.0 mm of the slide is not coated with the sample. This uncoated section is used to mount the slide in the diffractometer. 2 Sample Preparation Using Bakelite (method used by geologists) Usually the sample will be applied to a pressed Bakelite cylinder. This procedure will therefore be followed in most cases. You will use a press and a stainless-steel die. Use the die with a 1” diameter. The die set has the following components: 1) an outer die 2) a stainless steel cylindrical insert 3) the inner die 4) an aluminum sleeve 5) piston. First assemble the unit. Insert the cylindrical insert, polished side up, in the outer die. Then insert the inner die and finally the aluminum sleeve. As noted above, ground the sample very carefully. Add sufficient sample so that it will uniformly cover the bottom of the die assembly. Tap the die assembly to spread out the sample. Tamp the sample with an aluminum tamper that fits into the brass sleeve. Carefully remove the tamper and check for a uniform layer of the sample. Hold the inner stainless-steel die and carefully remove the aluminum sleeve. Add 3 heaping 1/4 teaspoons of Bakelite. Carefully insert the stainless-steel piston. Transfer the assembled die assembly to the table of the press. Turn on the power. Engage the clutch and slowly crank on the compressor control clockwise until the piston of the press engages. Then increase the pressure to 5 Ton and hold it for one minute. Release the pressure, slowly for the last ton of pressure. Turn the compressor control counterclockwise until the pressure drops to zero; then give the control another counterclockwise turn. Disengage the clutch. Dissemble the die assembly and remove the sample. Scrupulously clean the components of the die assembly. Residues of ionic salts can severely corrode the components of the die! PREPARATION OF THE X-RAY GENERATOR 1) The generator has a total-elapsed time counter. Record the time (starting time) in the log for the unit. 2) Power is supplied to the Norelco generator through a Voltage regulator located on the floor that produces a clean, constant voltage. Check that the supply is on. It should not be turned off and should be found in the ON state. 2) Open the valve for the water supply that cools the X-ray tube. The valve is located on the wall. The lab is crowded so be careful not to hit the goniometer as you approach the valve. The previous user should have moved the goniometer out of harm's way to the 2 = 80 position. If it is in a lowered position and susceptible to attack, consider using the POWDER software as described below to raise it up. The valve is closed when the yellow lever is perpendicular to the wall. (The water pressure should be at least 45 psig; the generator checks this parameter and a microswitch in the generator won’t close if the water pressure is too low.) 3) Check that the VOLTAGE and CURRENT KNOBS ON THE Norelco generator are in the full counterclockwise position. Also check that the current switch is in the MINIMUM MA position. Confirm that the shutters for the x-ray ports are closed. 4) Start the flow of the cooling water by pushing the START button on the front panel of the generator. Make sure that you hear the flow of water. 5) Start the generation of X-rays by pressing the ON button above the water START button. This button stays pushed in when engaged and the red warning light is illuminated. The light should go on within ca. 30 second. Wait ca. 5 min. for the generator to warm up. X-rays are now being generated although the flux is low when the Voltage and current are low. 6) Check that the copper X-ray tube is installed. The Voltage and current values provided below apply to this tube. If a different tube is installed, check with the Geology Department. The Voltage and current settings appropriate for a copper tube might burn out other, e.g. iron, tubes. 7) Slowly adjust the Voltage of the supply to 35 kV. 8) Turn the current switch from MINIMUM MA to OPERATE. The Voltage will drop below 35 kV. Do not re-adjust the Voltage back to 35 kV. 3 9) Slowly increase the current to 20 ma. Again, the Voltage will continue to drop but do not re-adjust the Voltage back to 35 kV. The X-ray tube is now producing a high flux of X-rays. INSERTION OF THE SAMPLE 1) Confirm that the shutters are closed! Control the shutters via the program. 2) Open the enclosure by sliding it to the right. 3) If your sample is applied to a pressed Bakelite cylinder (normal situation), load the sample into the aluminum holder and tighten down the springs. 4) Loosen the nut holding the circular plate on the mount. 5) Rotate the plate counterclockwise and remove it. 6) Remove any sample in the mount. 7) Using a wedge, e.g. a small screwdriver, depress the tight spring clip and insert the sample, e.g. the slide or the Bakelite cylinder) face up. Be careful not to push the sample in too far.. 8) Re-attach the circular chamber plate. To do this, hold the lever against the shutter button so that the plastic knob will not restrict the cover. Rotate the cover clockwise about 20º and tighten the central nut. You may have to push the nut in slightly to secure the sample chamber door. 9) Close the enclosure by sliding it to the left. You may have to apply gentle pressure to fully close it and close the microswitch. CONTROL OF THE SHUTTER The shutter mechanism is now interfaced with the computer. Please only open the shutter via computer control. You may damage the electronic interface if you open the shutter manually. Port 2 which you will be using feeds the Philips powder goniometer. Port 4 is permanently closed. Ports 1 and 3 are available for alternate goniometers and for a powder camera. The following information is provided for use of the technician. Do not fiddle with the control knob. A control knob for each port has 4 positions: 1) OFF, the shutter is closed. Turning the knob to this position will close the shutter. 2) , the shutter is open permanently. 3) A, the shutter is open for A hours (0A4 hours. A set by a dial). 4) B, the shutter is open for B hours (0B23 hours, B set by a dial) To open the shutter with the computer: 1)Make sure that the computer, and all the hardware is turned on; the black CrystalLogic control box has to be turned on before the computer or the program will not communicate properly with the interface. 2) Start the POWDER program by double clicking on the POWDER.exe icon, which displays the NaCl unit cell. 3) Click on Manual from the top menu line. A new window will appear that enables direct control of the goniometer and shutter (Figure 2). The shutter can be opened by clicking on the Shutter button. Go back to the main window POWDER by clicking Cancel. (To manually open a shutter, (NOT for student use!!): turn the control knob to , A, or B. In the case of the A or B settings, set the appropriate time. Press the SHUTTER OPEN button. The shutter will open and a light will go on. If the bulb for the light burns out, the shutter will close.) The shutter is associated with variable slits. The slits are varied under program control to provide a constant illuminating area for all values of 2. This was not the case with older constant-slit units with resulting systematic errors in intensities. ACQUISITION OF DATA As mentioned before, the system is controlled by an interface designed by CrystalLogic under CrytstalLogic software. Separate software, PowderX, is used to analyze the raw data. If you used the computer to open the shutters then you can proceed to the procedure explained below. If you manually opened the shutters then make sure that the computer, and all the hardware is turned on; the black CrystalLogic control box 4 found to the right of the PC has to be turned on before starting the software. Initiate the control software by clicking on the POWDER.exe icon which displays the NaCl unit cell. The POWDER window (Figure 1) has four sections, starting from the top: 1) the menu line 2) a panel with colorless fields for inputting control parameters, e.g. the initial value of 2, and green fields for displaying the status of the instrument, e.g. the current value of 2. 3) the diffraction pattern, either directly measured or downloaded from a dataset 4) a panel for providing information that is appended to a file that is created for each run. None of the parameters entered in this panel are measured directly, e.g. the wavelength of the X-rays. The file button in the bottom panel is used to provide the path, file name, and format of the file that is created. The following simple procedure will yield a useful dataset. 1) Turn on the CrystalLogic control box first or the program will not communicate properly with the interfacl 2) Start the POWDER program by double clicking on the POWDER.exe icon. 3) Click on the File button in the buttom panel and provide the format for the dataset to be produced (I recommend the default .dat format), the path (consider saving your data on a 3.5" diskette so the hard drive is not cluttered), and the file name for your data. 4) Check that the current setting of the monochromator is synchronized with the interface. Click on Manual in the top menu line. A new window will appear that enables direct control of the goniometer (Figure 2). The sample changer and slit functions in the window do not function. The program's measurement of the current setting of the goniometer (2 in degrees) is displayed in a box. Read the actual setting of the goniometer. It should agree with the number in the box. If not, enter the actual value in the box and click on the Define button. A mistake at this point will introduce a serious systematic error! You can also change the position of the goniometer with the meter. Enter the value of 2 in degrees and click on Drive. The number which you select must fall in the range 0<2<125. Don't even come close to the limits. There is no reason to. The goniometer will move to the new position. To exit from the manual window, click on Cancel. 4) Provide the control parameters in the colorless (white) fields in the top panel: a) The initial value of 2 in degrees. This must be a positive, non-zero number. Consider for your first run a value of 5.0. There is no value in running lower than 5 as the intensity data in this regime is dominated by specular reflection. b) The final value of 2 in degrees. This must be less than 120. The goniometer has stop which prevent 2 from falling outside these limits but the stop does not always function. However, if a limit is reached, the goniometer must be reset manually by a technician so please do not tempt fate. Steer well clear of the limits. In the vast majority of experiments, there is no reason to come close. c) the goniometer step size in degrees. The position of the goniometer is controlled by a stepping motor and this parameter is the increment in 2. Optimal resolution is achieved with 0.02 and there is no value is running with a smaller value. However, higher resolution incurs longer run times. For a survey run, consider a step size of 0.1. d) the count time in seconds. For each setting of the goniometer, counts are accumulated over count time seconds. Consider 1 s in your first run. Increase the value if the signal-to-noise ratio is too low. Recall that the standard deviation of the mean is inversely proportional to the count time. 5) Insert your sample if you have not already done so and open the shutter on port 2. 6) Start the run by clicking on the Start button on the right side of the lower panel. The light in the PC window will turn from green to red and the shutter should open with an audible click. The goniometer should stop at each setting for the count time. If it does not and is rapidly stepped through its angular range, immediately stop the run by clicking on Abort before the goniometer reaches the stoop and jams. Consult the technician or your instructor if this happens. Also seek assistance if the shutter does not open. The detector is interfaced to a multi-channel analyzer. An X-ray photon passing through the NaI can produce a cascade of visible photons. The number of visible photons produced per X-ray photon is proportional to the energy of the X-ray photon. The electronics in effect a histogram of the number of detected X-ray photons versus the energy of the photons. For each setting of the goniometer, the total count 5 of all X-ray photons falling in a certain range is passed to the computer and the result is displayed in one of the green fields in the top panel and the diffraction pattern plotted in the center of the window. The range of useful data (channels 200 to 900) was determined via the scdw.exe routine when the instrument was installed. The graphical display of the results is automatically scaled . However, buttons on the left of the graph permit the user to expand or reduce the scaling. The results are displayed on the screen and are stored in the file specified in step (3). The green fields in the top panel display the number of counts at each setting of the goniometer and the time remaining for the run in seconds. You should notice that the data will be written to disk as the run proceeds. Windows is not a real-time operating system and writing to disk takes priority over control of the goniometer. 7) When the run has finished, close the shutter, this will automatically be done if the shutter was opened through the software. Consider making a second copy of your data by clicking on File and then Save As. Save As rd appears not to work properly. The program has very few features for the analysis of the results. A second program is used for that purpose. ANALYSIS OF THE DATA A flexible analysis program has been provided by Professor Cheng Dong of the Institute of Physics, Chinese Academy of Sciences, Beijing, People's Republic of China. A manual in Microsoft Word rtf format, Pxusere.rtf, can be found in the folder c:\xray-china. 1) Preparation of the ASCII file produced by POWDER. Professor Dong's program can read X-ray datasets in a number of formats. However, the POWDER .dat format is not on his list. However, a POWDER .dat file can be easily converted to an acceptable format, e.g. .xrd. In the following example, the file to be edited has the name test_WES.dat. A file in the POWDER .rd format can be converted to a Sietronics .cpi format that can be read by PowderX. However, the creation of a .xrd file from a .dat file is much simpler and will be described here. a) Make a copy of the original file with the extension .xrd. That is, the copy would be test_WES.xrd. b) Open the copy using Microsoft Notepad or Word. The POWDER .dat format consists of a multiline header followed by a data section. In the data section, each line contains the value of 2 in degrees and the number of counts. In editing the copy, strip off all lines of the header except for the first one, which reads: Sample Sample. This line which can be up to 80 characters long is used to identify the sample. This header line, e.g. sample junkite, should be followed by a new line which is the number of values of 2. Use a left-hand justified integer format. That is, no decimal points and no spaces at the left. This new line is immediately followed by the lines of data, one for each value of 2. Save the file. You are now ready to use PowderX. 3) Start the PowderX program by clicking on the PowderX icon on the Windows desktop. Windows should allow the user to run concurrent sessions of both POWDER and PowderX. The PowderX window is shown in Figure 1 attached to the end of this document. 4) Open a file for analysis by clicking on File and then Import Data. Select the .xrd format. Figure 3 displays the PowderX window and the diffraction pattern for sodalite. The sodalite2.dat file provided as a test file with POWDER was modified as described in step (1) and imported into PowderX. PowderX assumes that the X-ray generator uses a copper tube. 5) Follow these steps to generate a list of the peaks. a) Click on Peak in the menu line and then on Simple Peak in the submenu. b) A box for the input of the parameters, Select Points and Intensity Limit, appears. You may wish to choose the default values at first. Click on Show to see the consequences of your choice. The selected peaks are marked by a small tic mark. To remove weaker peaks from consideration, increase the value of Intensity Limit and/or Select Points. Decrease the value(s) to include weaker peaks. Once you are satisfied with the selection, click on OK. c) A Wavelength box now appears in which you select the X-ray source (the default is copper), mode of dispersion (angular dispersion, our case, is the default), and the radiation used. Unless one uses routines in PowderX to strip off contributions from Cu K 2 radiation, click on average. The correct wavelength, 1.54178 Å, appears in the box. This number can be changed. Click on OK when you are finished. d) A new menu appears for the input of the path and file name of the ASCII (txt) file where the results can be stored. 6 e) Finally, a window appears with the results. One can print the results directly using the File command in the menu line of the printer. The table includes for each peak the values of 2, d, peak intensity, peak area, and FWHM. PowderX provides a variety of routines to select peaks and to filter the data. The most useful of the lot is probably the baseline correction routine (click on Process, then Background, and finally Sonnerveld). However, experience with the sodalite test file indicates that they be used with caution. SHUTDOWN 1) Close the shutter and slide the enclosure back. 2) Remove the sample from the chamber. RE-attach the chamber cover and close the enclosure. 3) Turn the current control knob counterclockwise to the stop position. 4) Turn the current switch from the OPERATE to the MINIMUM MA position. 5) Turn the Voltage knob counterclockwise until snug. 6) Hit the OFF button to stop the generation of X-rays. 7) Wait until the Voltage drops to zero. If the unit has been used for several hours, wait 10 minutes to insure complete cooling of the X-ray tube. 8) Then, push the STOP button to turn off cooling water to the machine., 9) Verify that the current and Voltage knows are off (fully counterclockwise). 10) Close the valve for the cooling water. The valve is closed when the yellow lever is perpendicular to the wall. 11) Do not turn off the Voltage regulator for the X-ray generator. 12) Record the elapsed time in the log for the system. 13) Manually set the goniometer to 80. This will move it out of the way. Click on Manual in the command line to bring up the manual control window (Figure 2). Enter the value of 2 and click on Drive. Click on Cancel to exit and return to the main window. 13) Exit from the POWDER program by clicking on File and then Exit useXRD.doc 3 Sep. 2001, revised 5, 17 Sep. 2001, 12 Jan. 2004, WES Revised: Jan 16, 2003 by Geol Technician 7 Figure 1. Main window of POWDER. 8 Figure 2. Manual Control Window of POWDER. 9 Figure 3. powderX Window. The sodalite dataset is displayed.