BTEC 220_Standard Operating Procedure_Ion

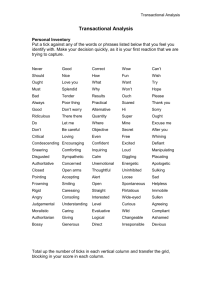

advertisement

MiraCosta College National Center of Excellence in Bioprocessing Part No. N/A Lot No. Page 1 Doc No. STANDARD OPERATING PROCEDURE BP012 CO No. N/A Subject: of 7 Rev No. C0004 001 Eff Date Ion Exchange Column Packing Procedure 25AUG06 1.0 PURPOSE: 1.1 Prepare an ion exchange chromatography column for use. 2.0 SCOPE: 2.1 Describe the appropriate operating instructions to pack an ion-exchange liquid chromatography column and evaluate packing quality. 3.0 RESPONSIBILITIES: 3.1 It is the responsibility of the course instructor/lab assistant to ensure that this SOP is performed as described and to update the procedure when necessary. 3.2 It is the responsibility of the students/technicians to follow the SOP as described and to inform the instructor about any deviations or problems that may occur while performing the procedure. 4.0 REFERENCES: 4.1 “Column Packing, The Movie” Amersham Biosciences 4.2 ÄktaPrime product manual 4.3 PrimeView software product manual 5.0 DEFINITIONS 5.1 a Front width of peak at 10% height, expressed as time or distance 5.2 b Back width of peak at 10% height, expressed as time or distance 5.3 HETP Height equivalent to a theoretical plate 5.4 h Height of a peak 5.5 L Length of packed column bed 5.6 N Theoretical plate count 5.7 Tris tris(hydroxymethyl)aminomethane 5.8 Ve Elution volume (volume eluted from column from the start of sample application to the peak maximum) 5.9 w Peak width, expressed as time or distance 5.10 w½ Peak width at half height, expressed as time or distance 5.11 Column Descriptions 5.11.1 Column end pieces. The red end pieces, made of reinforced acetal plastic, hold the chromatographic and jacket tubes in position. Each end piece houses an Oring, sealing ring, washer and locking ring. The end piece also carries a tubing connector through which thermostat fluid enters or leaves the column. 5.11.2 Column bottom piece. The bottom piece screws onto the column end piece . The gel bed is supported by a 10 μm nylon net ring on top of the plunger. The bottom piece seals against the chromatographic tube via the O-ring . 5.11.3 Adaptor. The adaptor consists of a top piece that fi ts the column end piece, a plunger that carries the gel bed protection and support screen, and adjusting mechanism. The adjusting mechanism allows the plunger to be set in position in MiraCosta College National Center of Excellence in Bioprocessing Part No. N/A Page 2 Doc No. STANDARD OPERATING PROCEDURE Lot No. BP012 CO No. N/A Subject: of 7 Rev No. C0004 001 Eff Date Ion Exchange Column Packing Procedure 25AUG06 the chromatographic tube, and forms the mechanism for sealing against the column wall. 5.11.4 Tubing. XK columns are supplied with fl anged M6-type capillary tubing. The adaptor tubing is 50 cm long. The bottom piece tubing is 30 cm long. A 5 cm protection tubing is threaded over the capillary tubing in the inlet of the adaptor and column bottom piece to prevent squeezing of the capillary tubing during transport and storage. 6.0 PRECAUTIONS 6.1 Wear safety goggles, gloves, and lab coats when packing a column because pressures can reach 50 psi. 6.2 The chromatography media is stored and flushed in 70% ethanol. It is harmful to eyes and mucous membranes. 7.0 MATERIALS and SUPPLIES 7.1 XK16 glass chromatography column (1.6 cm diameter, 20 cm. high ) assembly and associated components, such as ferrule tubing connectors 7.2 SP Sepharose Fast Flow cation exchange media (mean particle size = 90 m). 7.3 Reagent grade NaCl and acetone 7.4 Equilibration buffer: 0.1M Tris-HCl pH 6 (hereafter called “buffer”) 7.5 20% EtOH (ethanol), ultrapure water (upw) 7.6 Miscellaneous glass and plastic lab ware 8.0 EQUIPMENT 8.1 GE Healthcare ÄktaPrime system 8.2 Laptop with PrimeView software 9.0 PROCEDURE 9.1 Column Packing Procedure 9.1.1 Prepare Media Slurry 9.1.1.1 Equilibrate the chromatography media to the temperature of the anticipated separations process. 9.1.2 Assemble Column 9.1.2.1 Inspect all components, look for chips in ends of the glass column or holes in mesh or filters used to support the media. 9.1.2.1.1 You will use a mesh or filter pore size at least two times smaller than the smallest media particle size. 9.1.2.2 Equilibrate all components to the temperature at which the packing will be performed. 9.1.2.3 Assemble the bottom end-piece unit, making sure to securely fasten the tubing inside the end piece and adaptor. 9.1.2.4 Displace the air in the bottom end piece by flushing with 20% EtOH by using a syringe connected to the tubing. Ethanol will help break the MiraCosta College National Center of Excellence in Bioprocessing Part No. N/A Lot No. Page 3 Doc No. STANDARD OPERATING PROCEDURE BP012 CO No. N/A Subject: of 7 Rev No. C0004 001 Eff Date Ion Exchange Column Packing Procedure 25AUG06 surface tension and will not leave a hydrophobic film to entrap air. Remove the syringe adaptor and replace with a domed nut. 9.1.2.5 Leave a meniscus over the support ring and gently lay the mesh at an angle so no air is trapped underneath. Snap the top piece on top of the assembly. 9.1.2.5.1 Reference the picture in §10.1 9.1.2.6 Repeat the steps up until this point for the top adaptor 9.1.2.7 Insert the bottom end piece into the bottom of the column, tighten securely, and mount to a ring stand. 9.1.2.8 Check that the column is level. 9.1.2.9 Add buffer to a height of about 2 cm at the bottom of the column. 9.1.3 Pour Column 9.1.3.1 Shake the media slurry to ensure homogeneously mixed. 9.1.3.2 Pour the media into the column continuously, holding the column at an angle and minimizing bubble formation. Fill the column up to the top of the column until a meniscus of slurried solution is present at the column top. 9.1.3.3 Mount the column top adaptor and connect to a pump. 9.1.3.3.1 All connections upstream of the column should be made to ensure no bubbles are introduced. 9.1.3.4 Tighten all connections 9.1.3.5 Connect the bottom outlet to the top of the UV detector and run the column to check for any leaks or gaps. 9.1.4 Media Consolidation 9.1.4.1 Ideally, the column would be allowed to rest for all the media to settle out just by gravity. This would take too long, however. 9.1.4.2 The media consolidation can be thought of an accelerated gravity settling to speed up the process. 9.1.4.3 Pump buffer into the column at a rate of 20cm/hr until the bed stabilizes. 9.1.4.4 Maintain the packing flow rate for at least three column volumes after a constant bed height is achieved. 9.1.4.5 Mark the bed height on the column. 9.1.4.6 Loosen the top screw and release the side catch to allow the plastic thread assembly of the adaptor to be lowered to the media surface. 9.1.4.7 Slide the adaptor down to meet the media surface, expelling any liquid from the tube at the top as the adaptor is pressed down. 9.1.5 Constant Flow Column Packing 9.1.5.1 Turn the pump rate up to 500 cm/hr. 9.1.5.2 After the level of the column remains stable, pause the pump, loosen the top adaptor and the connection at the valve, and lower the top adaptor to again just above the surface of the packed media. MiraCosta College National Center of Excellence in Bioprocessing Part No. N/A Page 4 Doc No. STANDARD OPERATING PROCEDURE Lot No. BP012 CO No. N/A Rev No. C0004 Subject: of 7 001 Eff Date Ion Exchange Column Packing Procedure 25AUG06 9.1.6 Mechanical Compression Column Packing 9.1.6.1 After the media height stabilizes from several more CVs of flow, perform a final mechanical compression of the packed media. 9.1.6.2 Lower the top adaptor to about 3-mm below the surface of the gel bed and tighten the adaptor. 9.1.6.2.1 NOTE: Limit mechanical compression to 0.5-cm 9.1.6.3 After packing, the inlet and outlet tubes can be capped and the column stored until it is needed. 9.2 Column Evaluation Procedure 9.2.1 Prepare Efficiency Test Sample 9.2.1.1 10 mL 0.8 M NaCl and 1% (v/v) acetone in upw 9.2.1.1.1 This volume is sufficient for a class of 20 students 9.2.1.2 The salt solution will be detected by the conductivity sensor and the acetone will be detected by the absorbance detector. 9.2.2 Apply Efficiency Test Sample 9.2.2.1 Select a sample volume 0.5 – 1.0 % of Cv 9.2.2.2 Inject sample and run buffer through column at normal operational flow rate for media type. 9.2.2.3 Stop column after obtain both UV and conductivity peaks. 9.2.2.4 Measure Ve, w½, a, b values from plot of peak height vs. time/distance 9.2.3 Calculate Packing Quality Parameters 9.2.3.1 Calculate N, the number of theoretical plates using the formula: N = 5.54 × (Ve/w½)2 9.2.3.2 Calculate HETP using the formula: HETP = L/N 9.2.3.3 Calculate Hred using the formula: Hred = H/(mean particle size) 9.2.3.4 Calculate As (symmetry factor) using the formula: As = b/a 9.2.4 Evaluate Packing Quality Parameters 9.2.4.1 Compare calculated Hred to values shown in Table: Hred 2 2-4 3-5 Interpretation Ideal Good High efficiency applications 5-10 Low efficiency applications MiraCosta College National Center of Excellence in Bioprocessing Part No. N/A Page 5 Doc No. STANDARD OPERATING PROCEDURE Lot No. BP012 CO No. N/A Rev No. C0004 Subject: of 7 001 Eff Date Ion Exchange Column Packing Procedure 9.2.4.2 9.2.4.3 25AUG06 Compare calculated As to expected values shown in Table: As 1.0 0.8-1.5 0.8-1.5 Interpretation Ideal Good High resolution applications 0.5-5 Low resolution applications If Hred and/or As is outside the acceptable range for your application, then you should repack the column. MiraCosta College National Center of Excellence in Bioprocessing Part No. N/A Page 6 BP012 CO No. N/A Subject: Rev No. C0004 001 Eff Date Ion Exchange Column Packing Procedure 10.0 Doc No. STANDARD OPERATING PROCEDURE Lot No. of 7 25AUG06 ATTACHMENTS 10.1 10.2 XK-16 Schematic and Preparation for Packing 10.1.1 Remove air from the filter and fit the bottom piece to the XK column to be packed. Tighten the O-ring with the black adjusting knob. Close the outlet. 10.1.2 Attach the column that serves as reservoir. 10.1.3 Pour the gel suspension into the column. 10.1.4 Fit the XK adapter to the column and lower it to the surface of the gel suspension. Tighten the O-ring with the black adjusting knob. 10.1.5 Connect the inlet tubing from the XK adapter to the valve (pump). 10.1.6 Your column is now ready to pack. Flow calculations 10.2.1 From linear flow (cm/hour) to volumetric flow rate (ml/min) 10.2.2 From volumetric flow rate (ml/min) to linear flow (cm/hour) This product was funded by a grant awarded under the President’s High Growth Job Training Initiative as implemented by the U.S. Department of Labor’s Employment & Training Administration. The information contained in this product was created by a grantee MiraCosta College National Center of Excellence in Bioprocessing Part No. N/A Lot No. Page 7 Doc No. STANDARD OPERATING PROCEDURE BP012 CO No. N/A Subject: of 7 Rev No. C0004 001 Eff Date Ion Exchange Column Packing Procedure 25AUG06 organization and does not necessarily reflect the official position of the U.S. Department of Labor. All references to non-governmental companies or organizations, their services, products, or resources are offered for informational purposes and should not be construed as an endorsement by the Department of Labor. This product is copyrighted by the institution that created it and is intended for individual organizational, non-commercial use only.