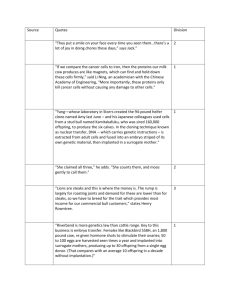

chapter 2

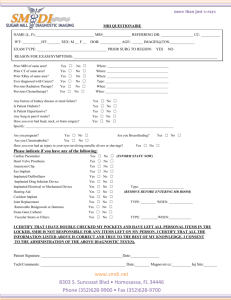

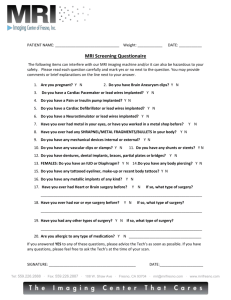

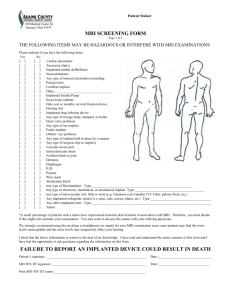

advertisement