Supporting Information Simulation of Rarefied Gas Flows in

advertisement

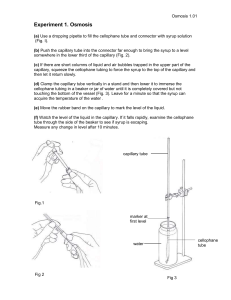

Supporting Information Simulation of Rarefied Gas Flows in Discontinuous Atmospheric Pressure Interface Mass Spectrometry Systems Sandilya Garimella1 , Xiaoyu Zhou1 and Zheng Ouyang1* 1 Weldon School of Biomedical Engineering, Purdue University *Corresponding Author: Zheng Ouyang Weldon School of Biomedical Engineering Purdue University 206 S. Martin Jischke Drive West Lafayette IN 47907 USA Email: ouyang@purdue.edu 1 S1. Knudsen Number in MS systems with DAPI and continuous interface Knudsen Number (Kn) is the ratio of mean free path of flow ( and the length scale of flow (L). Equation S1 Considering that the gas contained in the MS vacuum chamber is air and treating them as hard sphere molecules, the diameter of the molecules ( ) is 4.1x10-10m. The length scale of flow (L) is the diameter of the DAPI capillary. In the above equation the other terms used are - kB is Boltzmann Constant, p is pressure and T is Temperature. For a conventional atmospheric pressure interface of mass spectrometer, the pressure in the vacuum chamber (p) is around 1 torr. Considering a capillary of inner diameter 0.5 mm and at temperature 300K, the value of Knudsen Number of flow in the first stage of mass spectrometer with a conventional interface is Kn = 0.08. Thus the flow regime is on the border of continuum regime. If the pressure is lower, transition flow regime occurs. For a discontinuous atmospheric pressure interface, the base pressure of the vacuum chamber is 1 mTorr. The pressure rise in the vacuum chamber takes place during the DAPI open time. Typically the maximum allowed pressure in the vacuum chamber is about 0.5 Torr to operate within the limits of the turbo molecular pump. Therefore the Knudsen Number varies from 80 to 0.2. Thus the flow is in the transition regime flow during most of the operation time of DAPI. 2 S2. Gas expansion in MS systems with DAPI and continuous interfaces Continuous Interface 0.75mm i.d. capillary1 pb X 0.5 torr (fixed value) DAPI DAPI (0.5ms after DAPI opening) (2.0ms after DAPI opening) 0.1 torr (instantaneous at 0.5ms) 0.2 torr (instantaneous at 2.0ms) simulation theory simulation theory simulation theory 1.91cm 1.95cm 4.1cm 4.4cm 3.5cm 3.1cm 0.94 0.94cm 1.5cm 1.43cm 1.68 1.5cm axial extent of shock D Diameter of mach disk Theoretical expression for size of expansion shock structures has been reported previously.1 Equation S2 Here X is the axial spread of shock expansion and dmach is the diameter of mach disk, , p0 is the ambient pressure, pb is the vacuum chamber back pressure, dcapillary is the diameter of the capillary. 3 S3. Boundary conditions in DAPI simulations: The DAPI process introduces ions from ambient pressure conditions directly into the analyzer region at low vacuum pressure conditions. The flow dynamics inside the capillary leads to a pressure drop and velocity increase along the axis of the capillary towards the vacuum chamber. The boundary conditions for DAPI simulation have been set based on the exit pressure and velocity of DAPI capillary as inlet into the MS vacuum chamber. Pressure at exit of DAPI capillary: The value of pressure at DAPI capillary is calculated using the expression below (Equation S3.1). Here the pressure is in units of torr, the radius of capillary r and the length of the capillary L are in centimeters, µ is viscosity of air in poise, T is temperature in kelvin, M is the molecular weight of air in g/mol. Equation S3 Equation S4 This formulation is used to obtain the boundary conditions for pressure/number density for the simulation. Simulating the complete transport process through the capillary is computationally intensive using the DSMC method as the flow inside the capillary is in the continuum regime. Only the flow from exit of the capillary into the vacuum chamber suddenly changes and experiences a steep pressure drop and hence is in the transition regime. 4 Velocity at the exit of the DAPI capillary: Since the flow in the capillary is choked2, the axial velocity of gas inside the capillary gradually increases till it reached Mach 1 speed at the exit of the capillary.2-4 For the gas to obey the principle of continuity, speeds greater than Mach 1 cannot occur inside the capillary. The speed of sound in air is given by the expression ratio . For air with the value of specific heat , molecular weight M = 28g/mol, T = 300K, R = 8.314J/molK; the value of c can be calculated to be 353m/s. This value is used as the inlet boundary condition in the DAPI simulations as the gas exhausts into the vacuum chamber from the DAPI capillary exit. The gas velocity is assumed to be axially directed and radial velocity is assumed zero just at the exit of the capillary. Boundary Conditions: 1. For simulation data shown in Figure 1 Condition 0.6mm i.d. capillary Pressure at capillary exit 380 torr Velocity at capillary exit 316 m/s Vacuum pressure 2 torr 2. For simulation data shown in Figure 2, Condition 0.50 mm i.d. capillary 5 Number density at capillary exit 1.1e25 m-3 Velocity at capillary exit 350 m/s Number density in vacuum 3.2e19 m-3 3. For simulation data shown in Figure 3, Condition 0.25mm i.d. capillary 1.0mm i.d. capillary Number density at capillary 1.1e25 m-3 exit Velocity at capillary exit 350 m/s 1.1e25 m-3 3.2e19 m-3 3.2e19 m-3 Number density in vacuum 350 m/s 4. For simulation data shown in Figure 4, Condition 0.5mm i.d. capillary Number density at capillary 1.1e25 m-3 exit Velocity at capillary exit 350 m/s Number density in vacuum 3.2e19 m-3 5. For simulation data shown in Figure 5, Condition 0.5mm i.d. capillary DAPI-1 Number density at capillary 1.1e25 m-3 exit Velocity at capillary exit 350 m/s 0.25 mm i.d. capillary DAPI-2 4.0e24 m-3 350 m/s 6 Number density in vacuum 3.2e19 m-3 3.2e19 m-3 7 S5. Diameter Characterization: Figure S1 b) a) 0.25mm i.d. capillary 1.00mm i.d. capillary 1.0 10 100 N/m2 1000 10000 N/m2 Figure S1 a) Contours of neutral density with 1.00m i.d capillary and b) 0.25mm i.d. capillary 8 LIST OF REFERENCES (1) (2) (3) (4) Jugroot, M.; Groth, C. P. T.; Thomson, B. A.; Baranov, V.; Collings, B. A. Journal of Physics D: Applied Physics 2004, 37, 1289-1300. Lin, B. W.; Sunner, J. Journal of the American Society for Mass Spectrometry 1994, 5, 873-885. Anderson, J. D. Modern Compressible Flow, 2nd Edition, ed., 1990. Robert W. Fox , A. T. M., Philip J. Pritchard Introduction to Fluid Mechanics 2006. 9