CHROMATOGRAPHY IN GENERAL

advertisement

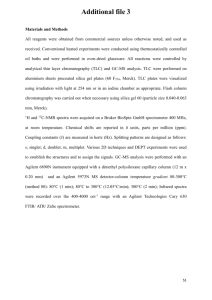

CHEM 3224 Page 1 of 4 SEPARATION AND PURIFICATION OF PRODUCT BY CHROMATOGRAPHY CHROMATOGRAPHY IN GENERAL Chromatography is defined as the separation of a mixture of two or more compounds by distribution between two phases, one of which is stationary and one of which is moving. Chromatography is so called because it was originally used to separate substances of different colors. Various types of chromatography are possible depending on the nature of the two phases involved: solid-liquid, liquid-liquid, and gas-liquid chromatographic methods are commonly available. TLC and column chromatography are often used in conjunction with each other. It is often convenient to investigate a suitable solvent system for the best mixture separation by TLC, since TLC is much quicker than running a column. The solvent system may then be used to elute the column and should give approximately the same types of separation, if the adsorbents are of similar activity. Both solid-liquid methods have great usefulness to the organic chemist. Both methods rely on a stationary solid phase and a mobile liquid phase. The solid phase is usually either silica gel (SiO2 x H2O) or alumina (Al2O3 x H2O). Some TLC Developing solvents INCREASING POLARITY Alkanes (hexane, cyclohexane, pet ether) Carbon tetrachloride Toluene Dichloromethane Chloroform Ethyl Acetate Isopropyl alcohol Acetone Ethanol Water Approximate Polarity of Organic Compounds INCREASING POLARITY Alkanes Alkenes Conjugated dienes Aromatic hydrocarbons Ethers, Halocarbons Aldehydes, Ketones, Esters Amines Alcohols Carboxylic acids DRY COLUMN “FLASH” CHROMATOGRAPHY The technique as described below combines the advantages of standard flash chromatography (good separation, speed) with the cheapness of material and simplicity of apparatus and operation. The distinctive feature of this method is the use of suction as opposed to positive pressure, simplifying loading of the product mixture and subsequent eluting solvents. A second feature is that the eluting solvents are added in predetermined volumes, allowing the column to run dry before adding the next fraction. CHEM 3224 Page 2 of 4 SEPARATION AND PURIFICATION OF PRODUCT BY CHROMATOGRAPHY The apparatus is set up as for vacuum filtration using a porosity 3 cylindrical sinter. Guidelines for sinter sizes, weight of silica and ranges of sample weight are shown below: Sinter Size (mm) Diameter/Height 30/45 40/50 70/55 Wt. Of Silica (g) 15 30 100 Sample Wt. 15-500mg 500mg-3g 2-15g Solvent Fraction volume (ml) 10-15 15-30 20-50 Use of column lengths appreciably longer than 55mm are not practical, nor are they necessary. Some lowering of efficiency may be noticeable with the large scale set-up. Method for performing vacuum flash chromatography Fill the sinter to the lip with silica and then apply suction, pressing down the silica with extra care at the circumference. Level the surface, pressing down all the time and finally tap the sides of the sinter firmly to obtain a totally level surface. The compacting of the silica thus provides a head space for the addition of product and solvents. Continuing suction, pre-elute the column with the least polar combination of the required solvents in which the product mixture is readily soluble. If possible, use pure least polar component for this (e.g., for pentane/ether gradient elution, pre-elute with pentane). If the silica has been packed correctly, the solvent front will be seen descending in a horizontal line. If channeling is apparent, suck the column dry and repeat the packing procedure. Keep the surface of the silica covered with solvent during the pre-elution until solvent is seen passing into the receiver, and then allow the silica to dry under suction. Load the mixture, dissolved in the minimum amount of the pre-elution system, evenly onto the surface of the silica and elute the products by adding successive portions of increasing polarity solvent mixtures, allowing the column to be sucked dry after each addition (the silica surface is particularly stable and is only slightly disturbed on addition of solvent). Generally a solvent gradient whereby the more polar component is increased by 5-10% is the most convenient. Under these conditions, the product is usually eluted by that solvent mixture which would cause it to have an Rf = 0.5 on TLC. In addition, for quantities >100 mg elution of product is often accompanied by frothing on the underside of the sinter. After a little experience, separations of the same efficiency as TLC are easily possible. There is minimal material loss and the technique is economical in both time and solvents. During prolonged chromatography with volatile solvents, condensation of atmospheric moisture may occur on the apparatus. This does not affect the efficiency of the separation but may be diminished by substituting less volatile solvents (e.g., hexane for pentane). No solvent is particularly disfavored for this technique, but combinations of pentane (hexane), ether, ethyl acetate and methanol are adequate for the vast majority of separation. The low diffusion of product bands during chromatography usually means that each component is eluted in one or two fractions with consequently minimal loss of product in cross contaminated fractions. (Flash chromatography from February, 1982, L.M. Harwood, University of Manchester) CHEM 3224 Page 3 of 4 SEPARATION AND PURIFICATION OF PRODUCT BY CHROMATOGRAPHY PROCEDURE Practical Information You will need a pencil, a calculator and a ruler for this experiment, in addition to your laboratory notebook, pen and safety glasses. In this experiment, you will be utilizing commercially prepared TLC plates. These thin plates are in the form of large square sheets, which you will need to carefully cut to the appropriate size. Visualization of your compounds on these plates can be accomplished via a UV lamp, and is to be done only under the strict supervision of the instructor or the teaching assistant, due to the potential for eye injury from improper use of the UV lamp. Application of the compounds to the TLC plates will be accomplished using commercially available microcapillary pipettes. The student will not be required to prepare his/her own pipettes. Experiment: THIS IS THE ONLY PART THAT YOU WILL BE PERFROMING: OBJECTIVE IS TO CHOOSE THE BEST SOLVENT OR SOLVENT MIXTURE THAT WOULD BE USED TO DEVELOP A LARGE SAMPLE OF A MIXTURE OF N,N’-diethl-m-toluamide AND META- TOLUIC ACID. 1. Prepare enough TLC plates and developing jars to develop N,N’-diethl-m-toluamide and m-toluic acid in each of the following four solvents (i.e., there will be four slides, each slide having been spotted with separate spots of the two compounds and those four slides developed in each of the four solvents): a. b. c. d. Petroleum ether (pet ether) Ethyl acetate 1:3 mixture of pet ether to ethyl acetate 3:1 mixture of pet ether to ethyl acetate 2. Develop the TLC plates 3. Using a pencil, mark the final areas of the compounds on the developed TLC plates 4. From the areas marked in step 3, calculate Rf values for each compound in each of the solvents 5. Using a mixture of the two compounds, develop the mixture on the following two solvents (i.e., there will be two slides – one for each compound, each slide having been spotted with the mixture): a. 1:3 mixture of pet ether to ethyl acetate b. 3:1 mixture of pet ether to ethyl acetate 6. Calculate the Rf values for each compound on each of the two slides. CHEM 3224 Page 4 of 4 SEPARATION AND PURIFICATION OF PRODUCT BY CHROMATOGRAPHY 7. Based on the results from steps 5 and 6, determine which solvent mixture would provide the best separation of the two compounds in a larger scale vacuum flash chromatography experiment. NOTE: Include reasons for your determination of solvent mixture (step 6) in your notebook. NOTE: Include TLC plates and/or sketches of TLC results in your notebook.