Product Stewardship in North America and Europe

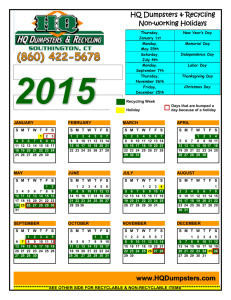

advertisement