chapter7_section5

advertisement

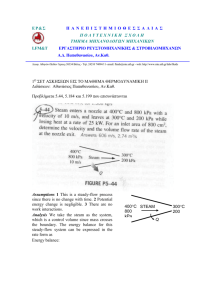

Chapter 7 Entropy Review Problems 7-137 It is to be shown that the difference between the steady-flow and boundary works is the flow energy. Analysis The total differential of flow energy Pv can be expressed as d Pv Pdv vdP wb w flow wb w flow Therefore, the difference between the reversible steady-flow work and the reversible boundary work is the flow energy. 7-138E An insulated rigid can initially contains R-134a at a specified state. A crack develops, and refrigerant escapes slowly. The final mass in the can is to be determined when the pressure inside drops to a specified value. Assumptions 1 The can is well-insulated and thus heat transfer is negligible. 2 The refrigerant that remains in the can underwent a reversible adiabatic process. Analysis Noting that for a reversible adiabatic (i.e., isentropic) process, s1 = s2, the properties of the refrigerant in the can are P1 120 psia R-134 s1 s f @80 F 0.0774 Btu/lbm R 120 psia T1 80 F 80F s 2 s f 0.0774 0.0364 x2 0.2222 P2 30 psia s fg 0.2209 0.0364 s 2 s1 v v x v 0.01209 0.2222 1.5408 0.01209 0.3518 ft 3 /lbm 2 f 2 fg Thus the final mass of the refrigerant in the can is m 1.2 ft 3 V 3.411 lbm v1 0.3518 ft 3 /lbm 7-109 Leak Chapter 7 Entropy 7-139 An insulated rigid tank is connected to a piston-cylinder device with zero clearance that is maintained at constant pressure. A valve is opened, and some steam in the tank is allowed to flow into the cylinder. The final temperatures in the tank and the cylinder are to be determined. Assumptions 1 Both the tank and cylinder are well-insulated and thus heat transfer is negligible. 2 The water that remains in the tank underwent a reversible adiabatic process. 3 The thermal energy stored in the tank and cylinder themselves is negligible. 4 The system is stationary and thus kinetic and potential energy changes are negligible. Analysis (a) The steam in tank A undergoes a reversible, adiabatic process, and thus s 2 = s1. From the steam tables, v v g @500kPa 0.3749 m 3 /kg P1 500 kPa 1 u u g @500kPa 2561.2 kJ/kg sat.vapor 1 s1 s g @500kPa 6.8213 kJ/kg K T2, A Tsat@150kPa 111.37 C s 2, A s f 6.8213 1.4336 P2 150 kPa x 2, A 0.9306 s fg 5.7897 s 2 s1 sat.mixture v 2, A v f x 2, A v fg 0.001053 (0.9306 )(1.1593 0.001053 ) 1.079 m 3 /kg u 2, A u f x 2, A u fg 466.94 (0.9306 )( 2052.7 kJ/kg ) 2377.2 kJ/kg The initial and the final masses in tank A are m1, A VA VA 0.4m 3 0.4m 3 1.067 kg and m 0.371kg 2, A v1, A 0.3749 m 3 /kg v 2, A 1.079 m 3 /kg Thus, m 2, B m1, A m 2, B 1.067 0.371 0.696 kg (b) The boundary work done during this process is Wb,out PdV P V 2 B 1 2, B 0 PB m 2, B v 2, B Taking the contents of both the tank and the cylinder to be the system, the energy balance for this closed system can be expressed as E E out E system in Net energy transfer by heat, work, and mass Change in internal,kinetic, potential,etc. energies Wb,out U U A U B Sat. vapor 500 kPa 0.4 m3 150 kPa Wb,out U A U B 0 or, PB m2, B v 2, B m2 u 2 m1u1 A m2 u 2 B 0 m2, B h2, B m2 u 2 m1u1 A 0 Thus, h2 , B m1u1 m2 u 2 A 1.067 2561 .2 0.3712377 .2 2659 .3kJ / kg m 2, B 0.696 At 150 kPa, hf = 467.11 and hg = 2693.6 kJ/kg. Thus at the final state, the cylinder will contain a saturated liquid-vapor mixture since hf < h2 < hg. Therefore, T2 , B Tsat @ 150 kPa 111.37 C 7-110 Chapter 7 Entropy 7-140 One ton of liquid water at 80°C is brought into a room. The final equilibrium temperature in the room and the entropy change during this process are to be determined. Assumptions 1 The room is well insulated and well sealed. 2 The thermal properties of water and air are constant at room temperature. 3 The system is stationary and thus the kinetic and potential energy changes are zero. 4 There are no work interactions involved. Properties The gas constant of air is R = 0.287 kPa.m3/kg.K (Table A-1). The specific heat of water at room temperature is C = 4.18 kJ/kgC (Table A-3). For air is Cv = 0.718 kJ/kgC at room temperature. Analysis The volume and the mass of the air in the room are 4m 5m 6m V = 4x5x6 = 120 m³ PV 100 kPa 120 m 3 m air 1 1 141.7 kg RT1 0.2870 kPa m 3 /kg K 295 K ROOM 22C 100 kPa Taking the contents of the room, including the water, as our system, the energy balance can be written as E E out in Net energy transfer by heat, work, and mass or Heat 0 U U water U air E system Water 80C Change in internal,kinetic, potential,etc. energies mC T2 T1 water mC v T2 T1 air 0 Substituting, 1000 kg 4.18 kJ/kg CT f 80 C 141.7 kg 0.718 kJ/kg C T f 22 C 0 It gives the final equilibrium temperature in the room to be Tf = 78.6C (b) Considering that the system is well-insulated and no mass is entering and leaving, the total entropy change during this process is the sum of the entropy changes of water and the room air, S total S gen S air S water where S air mC v ln S water mC ln T2 V mR ln 2 T1 V1 0 141.7 kg 0.718 kJ/kg K ln 351.6 K 17.86 kJ/K 295 K T2 351.6 K 1000 kg 4.18 kJ/kg K ln 16.61 kJ/K T1 353 K Substituting, the total entropy change is determined to be Stotal = 17.86 - 16.61 = 1.25 kJ/K 7-111 Chapter 7 Entropy 7-141E A cylinder initially filled with helium gas at a specified state is compressed polytropically to a specified temperature and pressure. The entropy changes of the helium and the surroundings are to be determined, and it is to be assessed if the process is reversible, irreversible, or impossible. Assumptions 1 Helium is an ideal gas with constant specific heats. 2 The cylinder is stationary and thus the kinetic and potential energy changes are negligible. 3 The thermal energy stored in the cylinder itself is negligible. 4 The compression or expansion process is quasi-equilibrium. Properties The gas constant of helium is R = 2.6805 psia.ft3/lbm.R = 0.4961 Btu/lbm.R (Table A-1E). The specific heats of helium are Cv = 0.753 and Cv = 1.25 Btu/lbm.R (Table A-2E). Analysis (a) The mass of helium is PV 25psia 15ft 3 m 1 1 0.264 lbm RT1 2.6805 psia ft 3 /lbm R 530 R HELIUM 15 ft3 PVn = const Then the entropy change of helium becomes S sys S helium T P m C p ,ave ln 2 R ln 2 T1 P1 760 R 70 psia (0.264 lbm) (1.25 Btu/lbm R )ln (0.4961 Btu/lbm R )ln 0.016Btu/R 530 R 25 psia (b) The exponent n and the boundary work for this polytropic process are determined to be P1V1 P2V2 T P 760 R 25psia 15ft 3 7.682 ft 3 V2 2 1 V1 530 R 70 psia T1 T2 T1 P2 n P V 70 15 2 1 n 1.539 25 7.682 P1 V2 Then the boundary work for this polytropic process can be determined from 2 P V P1V1 mR T2 T1 Wb,in P dV 2 2 1 1 n 1 n P2V2n n P1V1n 0.264 lbm 0.4961 Btu/lbm R 760 530 R 55.9 Btu 1 1.539 We take the helium in the cylinder as the system, which is a closed system. Taking the direction of heat transfer to be from the cylinder, the energy balance for this stationary closed system can be expressed as E E out E system in Net energy transfer by heat, work, and mass Change in internal,kinetic, potential,etc. energies Qout Wb,in U m(u 2 u1 ) Qout m(u 2 u1 ) Wb,in Qout Wb,in mC v (T2 T1 ) Substituting, Qout 55.9 Btu 0.264 lbm 0.753 Btu/lbm R 760 530 R 10.2 Btu Noting that the surroundings undergo a reversible isothermal process, its entropy change becomes Ssurr Qsurr ,in Tsurr 10.2 Btu 0.019 Btu / R 530 R (c) Noting that the system+surroundings combination can be treated as an isolated system, S total S sys S surr 0.016 0.019 0.003Btu/R 0 Therefore, the process is irreversible. 7-112 Q Chapter 7 Entropy 7-142 Air is compressed steadily by a compressor from a specified state to a specified pressure. The minimum power input required is to be determined for the cases of adiabatic and isothermal operation. Assumptions 1 This is a steady-flow process since there is no change with time. 2 Kinetic and potential energy changes are negligible. 3 Air is an ideal gas with variable specific heats. 4 The process is reversible since the work input to the compressor will be minimum when the compression process is reversible. Properties The gas constant of air is R = 0.287 kJ/kg.K (Table A-1). Analysis (a) For the adiabatic case, the process will be reversible and adiabatic (i.e., isentropic), thus the isentropic relations are applicable. T1 290 K Pr1 1.2311 and h1 290.16 kJ/kg 2 2 and Pr2 T2 503.3 K P2 700 kPa Pr1 (1.2311) 8.6177 h2 506.45 kJ/kg P1 100 kPa The energy balance for the compressor, which is a steady-flow system, can be expressed in the rate form as E E out in E system0 (steady) Rate of net energy transfer by heat, work, and mass AIR Rev. 1 0 Rate of change in internal,kinetic, potential,etc. energies E in E out h1 m h2 W in m (h2 h1 ) W in m Substituting, the power input to the compressor is determined to be W in (5/60 kg/s )(506.45 290.16 )kJ/kg 18.0 kW (b) In the case of the reversible isothermal process, the steady-flow energy balance becomes h1 Q out m h2 W in Q out m (h2 h1 ) 0 Q out E in E out W in m since h = h(T) for ideal gases, and thus the enthalpy change in this case is zero. Also, for a reversible isothermal process, Q m T s s m T s s out 1 2 2 1 where s 2 s1 s 2 s1 0 R ln P2 P 700 kPa R ln 2 0.287 kJ/kg K ln 0.5585 kJ/kg K P1 P1 100 kPa Substituting, the power input for the reversible isothermal case becomes W in (5/60 kg/s )(290 K)(0.5585 kJ/kg K) 13.5 kW 7-113 T = const 1 Chapter 7 Entropy 7-143 Air is compressed in a two-stage ideal compressor with intercooling. For a specified mass flow rate of air, the power input to the compressor is to be determined, and it is to be compared to the power input to a single-stage compressor. Assumptions 1 The compressor operates steadily. 2 Kinetic and potential energies are negligible. 3 The compression process is reversible adiabatic, and thus isentropic. 4 Air is an ideal gas with constant specific heats at room temperature. Properties The gas constant of air is R =0.287 kPa.m3/kg.K (Table A-1). The specific heat ratio of air is k = 1.4 (Table A-2) Analysis The intermediate pressure between the two stages is 100 kPa 27C 100 kPa 900 kPa 300 kPa Px P1 P2 900 kPa The compressor work across each stage is the same, thus total compressor work is twice the compression work for a single stage: kRT1 Px P1 k 1 / k 1 k 1 0.4/1.4 1.4 0.287 kJ/kg K 300 K 300 kPa 2 1 100 kPa 1.4 1 222.2 kJ/kg wcomp,in 2 wcomp,in, I 2 Stage I W Stage II 27C Heat and W in m wcomp,in 0.02 kg/s 222.2 kJ/kg 4.44kW The work input to a single-stage compressor operating between the same pressure limits would be wcomp, in and kRT1 P2 P1 k 1 / k 1 1.4 0.287 kJ/kg K 300 K 900 kPa k 1 1.4 1 100 kPa 0.4/1.4 1 263.2 kJ/kg W in m wcomp,in 0.02 kg/s 263.2 kJ/kg 5.26 kW Discussion Note that the power consumption of the compressor decreases significantly by using 2-stage compression with intercooling. 7-114 Chapter 7 Entropy 7-144 A three-stage compressor with two stages of intercooling is considered. The two intermediate pressures that will minimize the work input are to be determined in terms of the inlet and exit pressures. Analysis The work input to this three-stage compressor with intermediate pressures Px and Py and two intercoolers can be expressed as wcomp wcomp,I wcomp, II wcomp,III nRT1 nRT1 nRT1 1 Px P1 n 1 / n 1 Py Px n 1 / n 1 Px P1 n 1 / n n 1 n 1 n 1 nRT1 1 Px P1 n 1 / n 1 Py Px n 1 / n 1 Px P1 n 1 / n n 1 nRT1 3 Px P1 n 1 / n Py Px n 1 / n Px P1 n 1 / n n 1 The Px and Py values that will minimize the work input are obtained by taking the partial differential of w with respect to Px and Py, and setting them equal to zero: Py P x w n 1 1 0 Py n Px n 1 1 n w n 1 1 Px 0 Px n P1 P1 n 1 1 n n 1 1 n Py Px Py n 1 1 n P2 Py P2 n 1 1 n n 1 1 n 0 0 Simplifying, 1 Px P1 P1 Py P x 1 Px 1 n 1 n 1 Py Px Py 1 P2 Py P 2 2 n 1 n 2 n 1 n 1 P n 1 P1 Px 1 Px Pn P y y 1 2 n 1 Px 1 Py Pxn Py P2n P2 which yield P P Px2 P1 Px P2 Px P12 P2 Py2 P2 P1 Py Py 13 2 13 1 2 7-115 1 2 n Px21 n P1 Py 1n Py21 n Px P2 1 n Chapter 7 Entropy 7-145 Steam expands in a two-stage adiabatic turbine from a specified state to specified pressure. Some steam is extracted at the end of the first stage. The power output of the turbine is to be determined for the cases of 100% and 88% isentropic efficiencies. Assumptions 1 This is a steady-flow process since there is no change with time. 2 Kinetic and potential energy changes are negligible. 3 The turbine is adiabatic and thus heat transfer is negligible. Properties From the steam tables (Tables A-4 through 6) P1 7MPa h1 3410.3 kJ/kg T1 500 C s1 6.7975 kJ/kg K P2 1MPa h2 2879 .4 kJ / kg s 2 s1 7 MPa 500C STEAM 13.5 kg/s STEAM 15 kg/s I II 1 MPa s 3s s f 6.7975 1.0910 0.8775 P3 50 kPa x 3s s fg 6.5029 s 3 s1 h h x h 340 .49 0.8775 2305 .4 2363.5 kJ/kg 3s 3s fg f 50 kPa 10% 90% Analysis (a) The mass flow rate through the second stage is 3 0.9m 1 0.9 15kg/s 13.5 kg/s m We take the entire turbine, including the connection part between the two stages, as the system, which is a control volume since mass crosses the boundary. Noting that one fluid stream enters the turbine and two fluid streams leave, the energy balance for this steady-flow system can be expressed in the rate form as E E out in Rate of net energy transfer by heat, work, and mass E system0 (steady) 0 Rate of change in internal,kinetic, potential,etc. energies E in E out m 1h1 (m 1 m 3 )h2 Wout m 3h3 Wout m 1h1 (m 1 m 3 )h2 m 3h3 m 1 (h1 h2 ) m 3 (h2 h3 ) Substituting, the power output of the turbine is W out 15 kg/s 3410.3 2879.4 kJ/kg 13.5 kg 2879.4 2363.5 kJ/kg 14,930 kW (b) If the turbine has an adiabatic efficiency of 88%, then the power output becomes W a T W s 0.88 14,928 kW 13,140 kW 7-116 Chapter 7 Entropy 7-146 Steam expands in an 84% efficient two-stage adiabatic turbine from a specified state to a specified pressure. Steam is reheated between the stages. For a given power output, the mass flow rate of steam through the turbine is to be determined. Assumptions 1 This is a steady-flow process since there is no change with time. 2 Kinetic and potential energy changes are negligible. 3 The turbine is adiabatic and thus heat transfer is negligible. Properties From the steam tables (Tables A-4 through 6) Heat P1 8 MPa h1 3398.3 kJ/kg T1 500 C s1 6.7240 kJ/kg K 2 MPa P2 s 2 MPa h2 s 3000 .3 kJ/kg s 2 s s1 Stage I 2 MPa 500C Stage II P3 2 MPa h3 3467.6 kJ/kg T3 500 C s 3 7.4317 kJ/kg K 8 MPa 500C P4 s 100 kPa h4 s 2704.2 kJ/kg s 4s s3 100 kPa Analysis The power output of the actual turbine is given to be 80 MW. Then the power output for the isentropic operation becomes W s ,out W a,out / T (80,000 kW) / 0.84 95,240 kW We take the entire turbine, excluding the reheat section, as the system, which is a control volume since mass crosses the boundary. The energy balance for this steady-flow system in isentropic operation can be expressed in the rate form as E E out in Rate of net energy transfer by heat, work, and mass E system0 (steady) 0 Rate of change in internal,kinetic, potential,etc. energies E in E out m h1 m h3 m h2 s m h4 s W s,out W s,out m [( h1 h2 s ) (h3 h4 s )] Substituting, 95,240 kJ/s m (3398.3 3000.3) (3467.6 2704.2 )kJ/kg which gives 82.0 kg/s m 7-117 5 MW Chapter 7 Entropy 7-147 Refrigerant-134a is compressed by a 0.5-kW adiabatic compressor from a specified state to another specified state. The isentropic efficiency, the volume flow rate at the inlet, and the maximum flow rate at the compressor inlet are to be determined. Assumptions 1 This is a steady-flow process since there is no change with time. 2 Kinetic and potential energy changes are negligible. 3 The device is adiabatic and thus heat transfer is negligible. Properties From the R-134a tables (Tables A-11 through A-13) v 0.14549 m 3 /kg P1 140 kPa 1 h1 243.40 kJ/kg T1 10 C s1 0.9606 kJ/kg K 2 P2 700 kPa h 2 296.69 kJ/kg T2 60 C 0.5 kW R-134a P2 700 kPa h2 s 278.06 kJ/kg s 2 s s1 · V1 Analysis (a) The isentropic efficiency is determined from its definition, 1 h2s h1 278.06 24340 . 0.650 65.0% h2a h1 296.69 24340 . C 1 m 2 m . We take the actual compressor as the (b) There is only one inlet and one exit, and thus m system, which is a control volume. The energy balance for this steady-flow system can be expressed as E E out in Rate of net energy transfer by heat, work, and mass E system0 (steady) 0 Rate of change in internal,kinetic, potential,etc. energies E in E out W a,in m h1 m h2 (since Q ke pe 0) W a,in m (h2 h1 ) Then the mass and volume flow rates of the refrigerant are determined to be m W a ,in h2 a h1 0.5kJ/s 0.0094 kg/s 296.69 243.40 kJ/kg V1 m v1 0.0094 kg/s 0.14549 m 3 /kg 0.00137 m 3 /s 82L/min (c) The volume flow rate will be a maximum when the process is isentropic, and it is determined similarly from the steady-flow energy equation applied to the isentropic process. It gives m max V1,max W s ,in 0.5kJ/s 0.0144 kg/s 278.06 243.40 kJ/kg m max v1 0.0144 kg/s 0.14549 m 3 /kg 0.00210 m 3 /s 126 L/min h2 s h1 Discussion Note that the raising the isentropic efficiency of the compressor to 100% would increase the volumetric flow rate by more than 50%. 7-118 Chapter 7 Entropy 7-148E Helium is accelerated by a 94% efficient nozzle from a low velocity to 1000 ft/s. The pressure and temperature at the nozzle inlet are to be determined. Assumptions 1 This is a steady-flow process since there is no change with time. 2 Helium is an ideal gas with constant specific heats. 3 Potential energy changes are negligible. 4 The device is adiabatic and thus heat transfer is negligible. Properties The specific heat ratio of helium is k = 1.667. The constant pressure specific heat of helium is 1.25 Btu/lbm.R (Table A-2E). Analysis We take nozzle as the system, which is a control volume since mass crosses the boundary. The energy balance for this steady-flow system can be expressed in the rate form as E E out E system0 (steady) 0 in Rate of net energy transfer by heat, work, and mass Rate of change in internal,kinetic, potential,etc. energies 1 E in E out pe 0) m (h1 V12 / 2) m (h2 + V22 /2) (since Q W 0 h2 h1 V22 V12 V 2 V12 0 C p ,ave T2 T1 2 2 2 Solving for T1 and substituting, 0 1000 ft/s2 1Btu/lbm 21.25 Btu/lbm R 25,037 ft 2 /s 2 From the isentropic efficiency relation, T1 T2 a V22s V12 2C p 180 F N 196.0 F 656R h2 a h1 C P T2a T1 h2 s h1 C P T2 s T1 or, T2 s T1 T2 a T1 / N 656 640 656 / 0.94 639 R k 1 / k T2 s P2 From the isentropic relation, T1 P1 T P1 P2 1 T2 s k / k 1 656 R 14 psia 639 R 1.667/0.667 7-119 14.9 psia HELIUM N = 94% 2 Chapter 7 Entropy 7-149 [Also solved by EES on enclosed CD] An adiabatic compressor is powered by a direct-coupled steam turbine, which also drives a generator. The net power delivered to the generator and the rate of entropy generation are to be determined. Assumptions 1 This is a steady-flow process since there is no change with time. 2 Kinetic and potential energy changes are negligible. 3 The devices are adiabatic and thus heat transfer is negligible. 4 Air is an ideal gas with variable specific heats. Properties From the steam tables (Tables A-4 through 6) and air table (Table A-17), T1 295 K h1 295.17 kJ/kg , s1 1.68515 kJ/kg K T2 620 K h1 628 .07 kJ/kg, s 2 2.44356 kJ/kg K P3 12.5 MPa h3 3341.8 kJ/kg T3 500 C s 3 6.4618 kJ/kg K P4 10 kPa h4 h f x 4 h fg 191 .83 0.92 2392 .8 2393.2 kJ/kg x 4 0.92 s 4 s f x 4 s fg 0.6493 0.92 7.5009 7.5501 kJ/kg K in m out m . We take either Analysis There is only one inlet and one exit for either device, and thus m the turbine or the compressor as the system, which is a control volume since mass crosses the boundary. The energy balance for either steady-flow system can be expressed in the rate form as E E out in Rate of net energy transfer by heat, work, and mass E system0 (steady) 0 Rate of change in internal,kinetic, potential,etc. energies E in E out For the turbine and the compressor it becomes 1 MPa 620 K Compressor: air h1 m air h2 W comp, in m air (h2 h1 ) W comp, in m Turbine: steam h3 W turb, out m steam h4 W turb, out m steam (h3 h4 ) m Substituting, W comp, in 10 kg/s 628.07 295.17 kJ/kg 3329 kW 12.5 MPa 500C Air comp 0.98 kPa 295 K 10 kPa W turb,out 25 kg/s 3341.8 2393.2 kJ/kg 23,715 kW Therefore, W net,out W turb,out W comp, in 23,715 3329 20,386 kW Noting that the system is adiabatic, the total rate of entropy change (or generation) during this process is the sum of the entropy changes of both fluids, S m ( s s ) m (s s ) gen air 2 1 steam 4 3 where P 1000 kPa m air s 2 s1 m s 2 s1 Rln 2 10 kg/s 2.44356 1.68515 0.287 ln P1 98 kPa m steam s 4 s 3 25 kg/s 7.5501 6.4618 kJ/kg K 27.2 kW/K Substituting, the total rate of entropy generation is determined to be S gen,total S gen,comp S gen,turb 0.92 27 .2 28.12 kW/Κ 7-120 Steam turbine kJ/kg K 0.92 kW/K Chapter 7 Entropy 7-150 Problem 7-149 is reconsidered. The isentropic efficiencies for the compressor and turbine are to be determined, and then the effect of varying the compressor efficiency over the range 0.6 to 0.8 and the turbine efficiency over the range 0.7 to 0.95 on the net work for the cycle and the entropy generated for the process is to be investigated. The net work is to be plotted as a function of the compressor efficiency for turbine efficiencies of 0.7, 0.8, and 0.9. "Input Data" m_dot_air = 10"kg/s" "air compressor (air) data" T_air[1]=(295-273)"C" "We will input temperature in C" P_air[1]=98"kPa" T_air[2]=(700-273) "C" P_air[2]=1000"kPa" m_dot_st=25"kg/s" "steam turbine (st) data" T_st[1]=500"C" P_st[1]=12500"kPa" P_st[2]=10"kPa" x_st[2]=0.92"quality" "Compressor Analysis:" "Conservation of mass for the compressor m_dot_air_in = m_dot_air_out =m_dot_air" "Conservation of energy for the compressor is:" E_dot_comp_in - E_dot_comp_out = DELTAE_dot_comp DELTAE_dot_comp = 0 "Steady flow requirement" E_dot_comp_in=m_dot_air*(enthalpy(air,T=T_air[1])) + W_dot_comp_in E_dot_comp_out=m_dot_air*(enthalpy(air,T=T_air[2])) "Compressor adiabatic efficiency:" Eta_comp=W_dot_comp_in_isen/W_dot_comp_in W_dot_comp_in_isen=m_dot_air*(enthalpy(air,T=T_air_isen[2])-enthalpy(air,T=T_air[1])) s_air[1]=entropy(air,T=T_air[1],P=P_air[1]) s_air[2]=entropy(air,T=T_air[2],P=P_air[2]) s_air_isen[2]=entropy(air, T=T_air_isen[2],P=P_air[2]) s_air_isen[2]=s_air[1] "Turbine Analysis:" "Conservation of mass for the turbine m_dot_st_in = m_dot_st_out =m_dot_st" "Conservation of energy for the turbine is:" E_dot_turb_in - E_dot_turb_out = DELTAE_dot_turb DELTAE_dot_turb = 0 "Steady flow requirement" E_dot_turb_in=m_dot_st*h_st[1] h_st[1]=enthalpy(steam,T=T_st[1], P=P_st[1]) E_dot_turb_out=m_dot_st*h_st[2]+W_dot_turb_out h_st[2]=enthalpy(steam,P=P_st[2], x=x_st[2]) "Turbine adiabatic efficiency:" Eta_turb=W_dot_turb_out/W_dot_turb_out_isen W_dot_turb_out_isen=m_dot_st*(h_st[1]-h_st_isen[2]) s_st[1]=entropy(steam,T=T_st[1],P=P_st[1]) h_st_isen[2]=enthalpy(steam, P=P_st[2],s=s_st[1]) "Note: When Eta_turb is specified as an independent variable in the Parametric Table, the iteration process may put the steam state 2 in the superheat region, where the quality is undefined. Thus, s_st[2], T_st[2] are calculated at P_st[2], h_st[2] and not P_st[2] and x_st[2]" s_st[2]=entropy(steam,P=P_st[2],h=h_st[2]) T_st[2]=temperature(steam,P=P_st[2], h=h_st[2]) s_st_isen[2]=s_st[1] "Net work done by the process:" W_dot_net=W_dot_turb_out-W_dot_comp_in 7-121 Chapter 7 Entropy "Entropy generation:" "Since both the compressor and turbine are adiabatic, and thus there is no heat transfer to the surroundings, the entropy generation for the two steady flow devices bec omes:" S_dot_gen_comp=m_dot_air*( s_air[2]-s_air[1]) S_dot_gen_turb=m_dot_st*(s_st[2]-s_st[1]) S_dot_gen_total=S_dot_gen_comp+S_dot_gen_turb "To generate the data for Plot Window 1, Comment out the line ' T_air[2]=(700 -273) C' and select values for Eta_comp in the Parametric Table, then press F3 to solve the table. EES then solves for the unknown value of T_air[2] for each Eta_comp." "To generate the data for Plot Window 2, Comment out the two lines ' x_st[2]=0.92 quality ' and ' h_st[2]=enthalpy(steam,P=P_st[2], x=x_st[2]) ' and select values for Eta_turb in the Parametric Table, then press F3 to solve the table. EES then solves for the h_st[2] for each Eta_turb." W [kW] 20124 21745 23365 24985 26606 S [kW/K] 27.59 22.51 17.44 12.36 7.281 0.75 0.8 0.85 0.9 0.95 0.6665 0.6665 0.6665 0.6665 0.6665 Effect of Turbine Efficiency on Net Work and Entropy Generated 27000 30 comp = 0.6665 26000 25 20 24000 23000 15 22000 10 21000 20000 0.75 0.78 0.80 0.83 0.85 turb 7-122 0.88 0.90 0.93 5 0.95 Sgen,total [kW/K] Wnet [kW] 25000 Chapter 7 Entropy 7-151 Two identical bodies at different temperatures are connected to each other through a heat engine. It is to be shown that the final common temperature of the two bodies will be T f T1T2 when the work output of the heat engine is maximum. Analysis For maximum power production, the entropy generation must be zero. Taking the source, the sink, and the heat engine as our system, which is adiabatic, and noting that the entropy change for cyclic devices is zero, the entropy generation for this system can be expressed as S gen S source S engine0 S sink 0 mC ln ln Tf T1 ln Tf T2 Tf T1 0 mC ln 0 ln Tf Tf T1 T2 Tf T2 0 m, C T1 0 T f2 T1T2 and thus QH HE T f T1T2 W QL for maximum power production. m, C T2 7-123 Chapter 7 Entropy 7-152 The pressure in a hot water tank rises to 2 MPa, and the tank explodes. The explosion energy of the water is to be determined, and expressed in terms of its TNT equivalence. Assumptions 1 The expansion process during explosion is isentropic. 2 Kinetic and potential energy changes are negligible. 3 Heat transfer with the surroundings during explosion is negligible. Properties The explosion energy of TNT is 3250 kJ/kg. From the steam tables (Tables A-4 through 6) v1 v f @ 2MPa 0.001177 m 3 /kg P1 2 MPa u1 u f @ 2MPa 906.44 kJ/kg Sat.liquid s1 s f @ 2MPa 2.4474 kJ/kg K P2 100 kPa u f 417 .36, u fg 2088.7 kJ/kg s 2 s1 s f 1.3026 , s fg 6.0568 kJ/kg K x2 s2 s f s fg Water Tank 2 MPa 2.4474 1.3026 0.189 6.0568 u 2 u f x 2 u fg 417 .36 0.189 2088 .7 812.1 kJ/kg Analysis We idealize the water tank as a closed system that undergoes a reversible adiabatic process with negligible changes in kinetic and potential energies. The work done during this idealized process represents the explosive energy of the tank, and is determined from the closed system energy balance to be E E out in Net energy transfer by heat, work, and mass E system Change in internal,kinetic, potential,etc. energies Wb,out U m(u 2 u1 ) E exp Wb,out mu1 u 2 where m 0.1m 3 V 85.0 kg v1 0.001177 m 3 /kg Substituting, Eexp 85.0 kg 906.44 812.1kJ/kg 8019 kJ which is equivalent to mTNT 8019 kJ 2.47 kg TNT 3250 kJ / kg 7-124 Chapter 7 Entropy 7-153 A 0.2-L canned drink explodes at a pressure of 1 MPa. The explosive energy of the drink is to be determined, and expressed in terms of its TNT equivalence. Assumptions 1 The expansion process during explosion is isentropic. 2 Kinetic and potential energy changes are negligible. 3 Heat transfer with the surroundings during explosion is negligible. 4 The drink can be treated as pure water. Properties The explosion energy of TNT is 3250 kJ/kg. From the steam tables (Tables A-4 through 6) v1 v f @1MPa 0.001127 m 3 /kg P1 1 MPa u1 u f @1MPa 761.68 kJ/kg Comp.liquid s1 s f @1MPa 2.1387 kJ/kg K P2 100 kPa u f 417 .36, u fg 2088.7 kJ/kg s 2 s1 s f 1.3026 , s fg 6.0568 kJ/kg K x2 s2 s f s fg 2.1387 1.3026 0.138 6.0568 COLA 1 MPa u 2 u f x 2 u fg 417 .36 0.138 2088 .7 705.6 kJ/kg Analysis We idealize the canned drink as a closed system that undergoes a reversible adiabatic process with negligible changes in kinetic and potential energies. The work done during this idealized process represents the explosive energy of the can, and is determined from the closed system energy balance to be E E out in Net energy transfer by heat, work, and mass E system Change in internal,kinetic, potential,etc. energies Wb,out U m(u 2 u1 ) E exp Wb,out mu1 u 2 where m Substituting, 0.0002 m 3 V 0.177 kg v1 0.001127 m 3 /kg Eexp 0.177 kg 761.68 705.6 kJ/kg 9.9 kJ which is equivalent to mTNT 9.9 kJ 3250 kJ/kg 0.00305 kgTNT 7-125