Course: heat engines & combustion (a) Third

advertisement

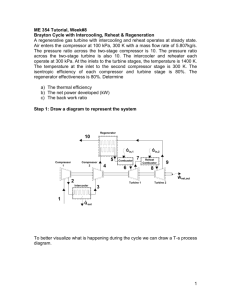

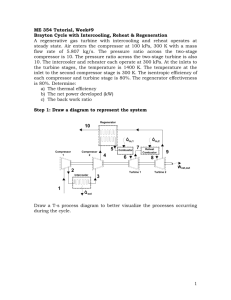

Course: heat engines & combustion (a) Third-year Mechanical Power Engineering Exam date 4-1-2012 Course Instractor : Prof. Dr. Ramadan Youssef Sakr 1a) environmental impact for steam power station is summarized in i- The temperature rise in the cooling water required fir condenser which affect the ecological life for the nearby river. ii- The exhaust gases discharged from chimney due to fuel combustion. iii- Noise due to exhaust steam. 1b) A steam turbine receives superheated steam at 20 bar. A part of the steam (6.5 tons/hr) is extracted to be used in an industrial process. At the point of extraction the pressure is 3 bar and the temperature is 180 °C. The remaining steam continues to expand down to the condenser vacuum pressure which is 69cm Hg. The isentropic efficiency in each of the two parts of the turbine is 75 %. The indicated power of the turbine is 2500 kW. Find the following: i) The initial temp, of the steam supplied to the turbine. ii) The total amount of steam to be supplied to the turbine per hour. 1 T Turbine 1 2 Industrial process 2s 2 3 3s 3 Condenser s Given : p1=20 bar mprocess =6.5 tons/h = 1.805 kg/s P2= bar, t2=180 C, p3=69 cm Hg vacuum = (1-69/72) = 0.1 bar, isentropic efficiency of the turbine in both stages 75% and IP=2500 kW Required: T1 & ms Solution: To get the temperature of the state point 1, use trial and error process as follows: No. 1 2 3 (t1) 350 355 354 (h1) 3138 3150 3148 T1=354 C h1= 3148 WT = ms(h1-h2)+(ms-mprocess) (h2-h3) 2000 = ms(3148-2825)+(ms-1.805)(2825-2423.8) So, ms= (2000-729.581)/724.2=3.7617 kg/s = 13.5 tons/hr (h2s) 2710 2718 2716 (hpt) 73.4% 75.5% 75% 2a) The use of multistage compression with intercooling and multistage expansion with reheating in gas turbine cycle both reduced the power required to drive the compressor and increase the power output from the turbine so increase the thermal efficiency of the cycle and in the limit the cycle will approach the air standard Striling cycle. 2b) A gas-turbine plant operates on the regenerative Brayton cycle. The isentropic efficiency of the compressor, the effectiveness of the regenerator, the air-fuel ratio in the combustion chamber, the net power output, the back work ratio, the thermal efficiency, the second law efficiency, the exergy efficiencies of the compressor, the turbine, and the regenerator, and the rate of the exergy of the combustion gases at the regenerator exit are to be determined. Solution: Properties The properties of air at 500ºC = 773 K are cp = 1.093 kJ/kg·K, cv = 0.806 kJ/kg·K, R = 0.287 kJ/kg·K, and k = 1.357. (f) The second-law efficiency of the cycle is defined as the ratio of actual thermal efficiency to the maximum possible thermal efficiency (Carnot efficiency). The maximum temperature for the cycle can be taken to be the turbine inlet temperature. That is, 3a) Refrigerant-134a enters the condenser of a residential heat pump at 800 kPa and 55°C at a rate of 0.018 kg/s and leaves at 750 kPa subcooled by 3°C. The refrigerant enters the compressor at 200 kPa superheated by 4°C. Determine (a) the isentropic efficiency of the compressor, (b) the rate of heat supplied to the heated room, and (c) the COP of the heat pump. Also, determine (d) the COP and the rate of heat supplied to the heated room if this heat pump operated on the ideal vapor-compression cycle between the pressure limits of 200 and 800 kPa. 3b) Refrigerant-134a enters the condenser of a residential heat pump at 800 kPa and 55°C at a rate of 0.018 kg/s and leaves at 750 kPa subcooled by 3°C. The refrigerant enters the compressor at 200 kPa superheated by 4°C. Determine (a) the isentropic efficiency of the compressor, (b) the rate of heat supplied to the heated room, and (c) the COP of the heat pump. Also, determine (d) the COP and the rate of heat supplied to the heated room if this heat pump operated on the ideal vapor-compression cycle between the pressure limits of 200 and 800 kPa. 4-a) An air compressor receives air from the surroundings at 100 kPa and 21 °C. There is a 5.0 kPa drop through the intake valves, and the temperature at the end of intake is 38 °C. The discharge pressure is 475 kPa and there is a 25 kPa pressure drop through the discharge valves. Determine: (a) volumetric efficiency, ideal and actual; (b) the power if the piston displacement is 14.0 liters and the ideal intake volume is 11.2 liters. The compressor is operating at 200 rev/min and n = 1.35. Solution: p1 = 100-5 = 95 kPa po = 100 kPa p2 = 475 + 25 = 500 kPa , To = 294 K, Ti= 311 K to verify that p2> discharge pressure vol 11.2 0.8 14 95 294 0.72 100 311 vol actual 0.8 wcycle =n/(n-1) p1(v1 -v4 ) [(p2/p1)(n-1)/n -1] wcycle n p1 v-actual VPD [1 - (p 2 /p 1 ) (n -1)/n ] (n - 1) wcycle 1.35 100 (0.72) (0.014) [1 - (500/95) (0.35)/1.35 ] (1.35 - 1) = -2.1 kJ/cycle 2.1x 200 W 7 60 kW 4b) In the constant volume cycle the pressure and temperature at the beginning of the compression are 1 bar and 43 °C and at the end of compression the temperature is 323 °C respectively. Determine the air standard efficiency and the compression ratio. A four stroke petrol engine of six cylinders, with the above compression ratio develops 30 indicated kW power at 2400 r.p.m. The air fuel ratio is 14 volumetric efficiency is 0.82, and bore to stroke is 0.85. The specific gravity of the fuel is 0.78 and its calorific value is 40500 kJ/kg. Determine the bore and stroke, indicated thermal efficiency and the ratio between the efficiency of the engine and the efficiency of the air standard cycle. Solution: Constant volume cycle (Otto) P1=1 bar T1= 43+273 = 316 K T2=323+273 = 596 K Find A.S 4 stroke z = 6 IP=30 kW N=2400 rpm A/F=14, vol =0.82 L/D=0.85 s.g of fuel =0.78 CV=40500 kJ/kg Determine D, L, ith , rel T2=T1(rv)k-1 so, rv =4.88 A.S = 1-1/(rv)k-1 = 46.96% 2400 Va D 2 (0.85 D) .x0.82 x0.85 x6 65.69 D 3 4 2 x60 a p 10 5 1.1 RT 287 * 316 ma 72.26 D 3 Assume: V fuel 10l / h = 2.78x10-6 m3/s mf = 2.78x10-6 x 780 = 2.168x10-3 kg/s ma = 14x 2.168x10-3 = 30.352x10-3 kg/s 30.352x10-3 = 72.26 D3 so, D = 7.5 cm L=6.4 cm IP 30 ith 0.34 m f CV 2.168 x10 3 x40500 rel ith 0.34 0.72 A.S 0.4696