Indoor climate in animal houses is mostly influenced by:

advertisement

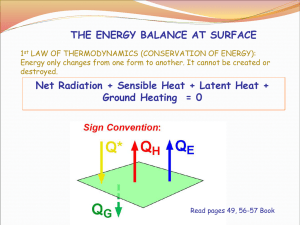

WP3 Food quality and safety T6 Animal welfare-environment-food quality interactions: production consequences. WP3T6L1EE Heat exchange in cowshed Heat and humidity balance in the cowshed Cowshed air exchange calculations can be based on the heat and humidity balance. Separate components of heat balance must be determined to find out total energy losses In livestock housing the main heat sources are animals. Energy is consumed to heat the ventilation air and compensate for the heat losses through boundaries and vaporization. Total, sensible or latent heat can be the basis for heat balance formula. Sensible heat balance of cowshed can be found with the following formula: (1) qv q s q p q a qo 0 where qv - sensible heat gain, W, qs -capacity of continuously powered equipment, W qp - heat losses through the building boundaries, W qa - heat losses due to vaporization from wet surfaces, W qo - heat loss due to ventilation, W Sensible heat gain qv Livestock produce various quantities of metabolic heat (total heat production qk) depending on the type of animal, its body weight, production and environmental conditions. A portion of heat is dissipated in the form of sensible heat qv (nonevaporative heat) and the rest as latent heat ql (evaporative heat). Emission rates are described in normatives, e.g. the normatives suggested by the International Commission of Agricultural Engineering (Commission Internationale du Geine Rural, CIGR). Total heat production rate (qk, W) for dairy cow is found on the basis of average feeding level at 20 ºC. (2) 0.75 5 3 qk 5.6m 1.6 10 t 22 p, where m – body mass, kg t – number of gestation days p – daily milk production, kg Total heat output rate might be adjusted according to the air temperature. k k 4 10 5 (20 ) 3 1 (3) - real air temperature, °C. For a 650 kg cow with milk production of 25 kg/day and 140 days of gestation, the total heat production is shown in figure 1. Total heat production, W 2500 2000 1500 1000 500 0 -7 -1 4 10 16 21 27 Environmental temp, °C Figure 1. Total heat production of 650 kg cow. If the environmental temperature is higher than +10 °C sensible heat rate (q watts) is found from the total heat output rate qk with the following ratio: 7 4 (4) qv qk 0.8 1.85 10 ( 10) v in Sensible heat production, W 2000 1500 1000 500 0 -7 -1 4 10 16 21 27 Environmental temp, °C Figure 2. Sensible heat loss in the cowhed. Latent heat rate (ql in watts) is: ql qk qv (5) Considering that 680 W·h/kg (2450 kJ/kg) is used to vaporize 1 kg water, the emitted amount of vapour from one animal w (kg/h) is found according to the following ratio: w 1.47 10 3 ql (6) Sensible heat and latent heat are the critical components of the heat and moisture balance. Sensible heat is useful in cold weather and a problem in hot weather. Latent heat must be removed from the building in cold weather and can be useful in hot weather. Heat losses through building boundaries, qp W Heat transfers from a high-temperature body to a low-temperature body. Heat exchange takes place by means of conduction, convection and radiation. Heat exchange through enclosures takes place mainly by conduction, which is specific for solid opaque bodies. Convection takes place in gases (e.g. air) and fluids and occurs at the boundary surface. Heat exchange by radiation is possible in the environments transparent for infra-red radiation (e.g. air, glass). Heat transfer (q) through multi-layer enclosure can be calculated with the following formula: s v qF 1 1 i (7) s i v where F – area of enclosure, m2 s – indoor air temperature , °C v – outdoor air temperature, °C άs – heat transfer coeff. from indoor air to wall, W/(m 2K) άv – heat transfer coeff. from wall to outdoor air , W/(m 2K) δ – thickness of structural component, m – thermal conductivity of structural component, W/(mK) 1 1 i is the reciprocal value of thermal conductance (U-value) and is s i v known as thermal resistance (R –value, (m²K)/W). Cowsheds are called either insulated or uninsulated. Insulated cowshed have multilayer boundaries which have significant thermal resistance (R-value) that uninsulated cowsheds conversely do not 1 2 3 have. <1 cm 10 cm 12,5 cm 10 cm s=15 ºC 1 3 v=-2o ºC = 0,5 v=5 ºC 0,04 0,9 W/(m·K) s=7 ºC =0,9 W/(m·K) R= 0,07 0,13 m2·K/W 0,01 R= 0,07 0,2 3,13 2 0,11 0,13 m ·K/W Rtot=0,07+0,2+3,13+0,11+0,13=3,64 m²K/W Rtot= 0,07+0,01+0,13=0,21m²K/W Figure 3. Temperature change in wall: 1 – masonry wall, 2 – heat insulation, 3– concrete wall, – thermal conductivity, 1 –outside surface temperature, 3 – inside surface temperature, v – outside temperature, s – inside temperature, R – thermal resistance Example 1 Heat losses through the boundaries in insulated and uninsulated cowshed Building 30*88 m, roof area 2735 m², walls area 708 m² (Figure 4) a) insulated: qroof=2735*(15-(-20))/3.64=26298 W qwalls=708*(15-(-20))/3.64=6808 W b) uninsulated: qroof=2735*(7-5)/0.21=26047 W qwalls=708*(7-5)/0.21=6743 W a) b) Figure 4. Heat losses through the boundaries in insulated (a) and uninsulated (b) cowshed (pay attention to the differences of ambient and indoor temperatures). Heat loss due to ventilation, qo W Heating and humidifying are the processes occurring in the cowshed (Figure 5 and 6). Sensible heat loss qo due to ventilation can be found by the formula qo= qv3 – qv1, (8) where qv3 – enthalpy of warmed air (W or kJ) qv1- enthalpy of ingoing air (W or kJ) qv3 – qv, expresses the amount of sensible heat added to ventilation air in kJ Figure 5. Moisture pickup by ventilation air exchange in livestock building. Figure 6. Heating and humidifying process in building (Esmay and Dixon, 1986). It is very convenient to use psychometric chart for calculations of enthalpy (Figure 6) or any other component of heating and humidifying process. Enthalpy is an energy content of water or an air water vapoure mixture (Esmay and Dixon, 1986). Note! The values of enthalpy are relative. It is 0 kJ/kg at 0°C and 0% of RH. Minus sign does not indicate at any deficit of enthalpy. 1 kg of outside air with temperature -20°C and RH 80% has enthalpy qv1= -18.8 kJ. (see point 1 at figure 6). Heating to temperature 15°C needs 16-(-18.8)= 34.8 kJ of sensible heat (point 3 at Figure 6). During the heating process specific volume of air increases from 0.717 to 0.817 m³/kg, humidifying to 15°C and 80% of RH 36.716.0=20.7 kJ (point 2 at Figure 6). Ventilation rates For the calculation of ventilation rates sensible and latent heat must be discussed separately. Ventilation rate Vair, sensible heat (l/s) for removing sensible heat can be calculated by the formula: Vair, sensible heat = (qo/(qv3-qv1))*v, (9) where v – specific volume of air in m³/kg Ventilation rate Vair , latent heat (l/s) for removing latent heat can be calculated by the formula: Vair , latent heat= (ql/(qv2-qv3))*v, (10) where qv2-qv3 - the latent heat difference between ambient and indoor air (kJ) Example 2: There are 300 cows in a cowshed described in example 1. Total heat production of cow at 15°C is about 1300 W (Figure 1). Sensible heat production per cow is 800 W (Figure 2) and latent heat production ql= 1300-800=500W. Ventilation rate for removing sensible heat can be calculated by formula 9. v = 0.827m³/kg at 15°C and 80% RH (also found in the psychometric chart). As qs and qa do not have significant value, sensible heat available for ventilation can be found by the formula: qv= qv-qp (11) qp=26298+6808=33106 W (Figure 4) qv=300*800-33106=206894 W Vair, sensible heat=206894/(16.0-(-18.8)*0.827=4917 l/s 4917/300= 16.4 l/s*cow Ventilation rate based on humidity (latent heat) balance Latent heat production in the cowshed is ql =300*500=150000 W and according to formula 10 Vair , latent heat=150000/(36.8-16.0)*0.827=5963 l/s. 5963/300 = 19.9 l/s*cow. Ventilation rate necessary for removing water vapour exceeds the ventilation rate available from sensible heat and extra heating is needed at the outside temperature of -20°C. If no supplemental heat is available condensation will build-up in the cowshed. By using formulas 9, 10 and 11 ventilation curves for different ambient temperatures can be drawn (Figure 7). Indoor conditions considered in example 1 and 2 show that ventilation is optimal at the ambient temperature -12...-13°C, when both ventilation rates are approximately the same. Removing sensible heat will cause a problem in warm and hot weather. In that case evaporative cooling a process of converting sensible heat to latent heat may be used. 40000 35000 Ventilation l/s 30000 25000 sensible heat 20000 latent heat 15000 10000 5000 0 -20 -15 -10 -5 0 5 10 ambient temp °C Figure 7. Ventilation curves for sensible and latent heat. Humidity balance can also be expressed through the amount of water vapour. The amount of water vapour of ambient (incoming) and indoor (outgoing) air can be found in the psychometric chart. Formula 6 is the basis for calculating the water vapour production by cattle. Literature Aerial Environment in Animal Housing. CIGR Working Group Report Series nr. 94.1. Climatization of Animal Houses. Report of Working Group CIGR, Commission Internationale du Gėnie Rural. Aberdeen, 1984. Esmay, M. L. and Dixon, J. E. 1986. Environmental Control for Agricultural Buildings. The AVI Publishing Company, Inc, Westport, Connecticut Livestock Housing. Edited by C. M. Wathes, D. R. Charles. CAB International, 1994, 428 p. Liiske, M. 2002. Sisekliima. Tartu: EPMÜ, 188 p.