Responsible manufacturing.

advertisement

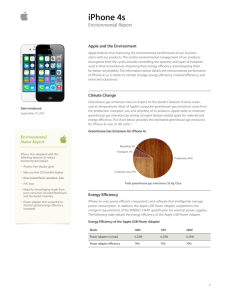

Apple and the Environment Manufacturing Manufacturing — including extraction of raw materials and product assembly — accounts for 61 percent of Apple’s total greenhouse gas emissions. Material use. Over the past decade, Apple’s designers and engineers have pioneered the development of smaller, thinner, and lighter products. As our products become more powerful, they require less material to produce and generate fewer carbon emissions. For example, although today’s 21.5-inch iMac is more powerful and has a much larger screen than the first-generation 15-inch iMac, it is designed with 50 percent less material and generates 50 percent fewer emissions. Even the iPad became 33 percent thinner and up to 15 percent lighter in just one generation, producing 5 percent fewer carbon emissions. Toxic substance removal. Designing greener products means considering the environmental impact of the materials used to make them. From the glass, plastic, and metal in our products to the paper and ink in our packaging, our goal is to continue leading the industry in reducing or eliminating environmentally harmful substances. One of the environmental challenges facing our industry today is the presence of toxic substances such as arsenic, brominated flame retardants (BFRs), mercury, phthalates, and polyvinyl chloride (PVC) in products. Although most countries still allow use of these substances, we have worked with our manufacturing partners to eliminate them from our products. Not only is every product we sell free of BFRs and other harmful toxins, we have also qualified thousands of components to be free of elemental bromine and chlorine, putting us years ahead of anyone else in the industry. In addition, every display we make — whether it’s built into a system or available as a stand-alone — features mercury-free LED backlighting and arsenic-free glass. Environmentally conscious materials. In addition to eliminating toxins and designing products with highly recyclable aluminum enclosures, Apple works with environmentally conscious materials including recycled plastics, recycled paper, biopolymers, and vegetable-based inks. We have also found ways to reengineer secondary materials to the high standard of our designs. For example, our fan assemblies use advanced materials derived from repolymerized plastic bottles. And millions of speaker assemblies and internal brackets are now made from recycled PC-ABS. Our packaging designs use pulp fiber from post-consumer paper streams, and we use vegetable-based inks for our product user guides. Millions of iPhone packages are made from renewable tapioca paper foam material. And iTunes gift cards are made from 100 percent recycled paper. Responsible manufacturing. Apple is committed to ensuring that working conditions in our supply chain are safe, workers are treated with respect and dignity, and manufacturing processes are environmentally responsible. View our Supplier Code of Conduct as well as our supplier audit reports at the Supplier Responsibility site. Apple’s attention to product design has led to significant reductions in carbon emissions compared with previous-generation products — even though new products are more powerful than ever. Our entire product line — Mac, iPod, iPhone, iPad, and accessories — is free from many toxic materials (including lead, BFR, PVC, mercury, and arsenic). Transportation Five percent of Apple’s greenhouse gas emissions are a result of transporting our products from assembly locations to distribution hubs in regions where our products are sold. Smaller packaging. Apple employs teams of design and engineering experts who develop product packaging that’s slim and light yet protective. Efficient packaging design not only reduces materials and waste, it also helps reduce the emissions produced during transportation. For example, the packaging for iPhone 4 is 42 percent smaller than for the original iPhone shipped in 2007. That means that 80 percent more iPhone 4 boxes fit on each shipping pallet, more pallets fit on each boat and plane, and fewer boats and planes are used — resulting in fewer CO2 emissions. By reducing iPhone packaging by 42 percent from 2007 to 2011, we ship 80 percent more boxes in each airline shipping container. That saves one 747 flight for every 371,250 units we ship.* Calculated using U.S. configurations. Product Use The use of our products generates 30 percent of Apple’s total greenhouse gas emissions.3 Energy efficiency. A significant portion of greenhouse gas emissions Apple accounts for are produced when you plug in our products and start using them. That’s why we design our products to be as energy efficient as possible. Because we design both the hardware and the operating system, we’re able to make sure they work together to conserve power. Take Mac mini, for example. Through innovations both big and small, it uses as little as one-fifth the power consumed by a typical lightbulb.4 Mac mini uses even less power than a single 13-watt CFL lightbulb, making it the most energy-efficient desktop computer in the world.5 Apple’s A5 chip in iPhone 4S and iPad 2, and the A4 chip in iPhone 4, iPod touch, and Apple TV are further examples of energy-efficient design. Apple engineers created the A5 and A4 chips to be extremely powerful yet remarkably energy efficient. With them, your Apple devices can perform complex jobs without sacrificing battery life. ENERGY STAR qualification. Unlike other manufacturers who may have one or a few products that are ENERGY STAR qualified, every single Apple product not only meets but exceeds the United States Environmental Protection Agency’s strict ENERGY STAR guidelines for efficiency. Apple is the only company in the industry that can make this claim. Recycling Two percent of Apple’s total greenhouse gas emissions are related to recycling. Product recyclability. Apple’s approach to recycling begins in the design stage, where we create compact, efficient products that require less material to produce. And the materials we do use — including arsenic-free glass, high-grade aluminum, and strong polycarbonate — are reclaimed by recyclers for use in new products. Even our product packaging uses recyclable materials wherever possible. Longer-lasting products. Apple designs products that last. The built-in battery in our MacBook Pro lineup is a perfect example. Other notebook batteries can be charged only 200 to 300 times. The MacBook Pro battery can be charged up to 1000 times.6 And because this battery lasts up to five years, MacBook Pro uses just one battery in about the same time a typical notebook uses three. That saves you money, produces less waste, and increases the lifespan of your MacBook Pro. Responsible recycling. All e-waste collected by Apple-controlled voluntary and regulatory programs worldwide is processed in the region in which it was collected. Nothing is shipped overseas for recycling or disposal. Our recyclers must comply with all applicable health and safety laws, and Apple does not allow the use of prison labor at any stage of the recycling process. Nor do we allow the disposal of hazardous electronic waste in solidwaste landfills or incinerators. Apple recycling programs. Once an Apple product reaches the end of its useful life, we will help you recycle it responsibly. Apple has instituted recycling programs in cities and college campuses in 95 percent of the countries where our products are sold, diverting more than 115,504 metric tons of equipment from landfills since 1994. Our goal in 2010 was to achieve a worldwide recycling rate of 70 percent. (To calculate this rate, we use a measurement proposed by Dell that assumes a seven-year product lifetime. The weight of the materials we recycle each year is compared to the total weight of the products Apple sold seven years earlier.) We met and exceeded that goal in 2010. This far surpasses the last reported numbers from Dell and HP, which were each lower than 20 percent. In 2011, Apple global recycling once again exceeded our 70 percent goal, and we are confident that we will maintain this level through 2015. From: http://www.apple.com/environment/#top