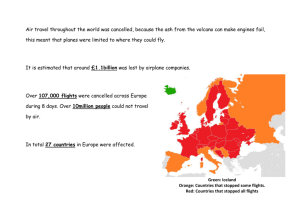

Hydro & Water

advertisement