ON BALANCE An Editorial in a Series by Harold S. Stein, Jr

advertisement

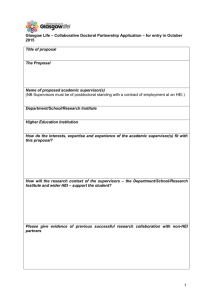

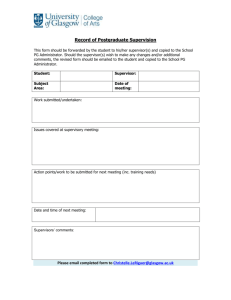

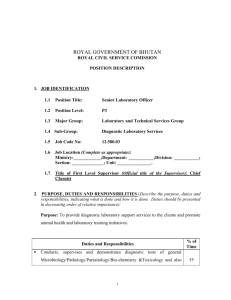

ON BALANCE An Editorial in a Series by Harold S. Stein, Jr., President Who Is a Supervisor at Crane? I confess to having opened up a can of worms with one question I asked our clients in a confidential survey about Crane’s services. Where I stumbled was in asking about adequate communication with our supervisors. In most instances the responses we received indicated that the question was “not applicable”. However, there was a group divided in sentiment between “Who is the supervisor?” and “Who needs one?” I should have known better, since Crane has purposefully built up its technical staff with what can officially be defined as “supervisory-qualified” personnel. You see, coming into this industry as a community pharmacist, I envisioned our technicians as practitioners and the physical properties we protect as our patients. For over a thirty-year span I selected, trained, equipped and compensated our present team to fulfill that role. Each one, as an essential requirement of the company, must possess the technical license from the Structural Pest Control Board that is required of a supervisor. Each must undergo the Continuing Education requirements for annual license renewal, while in turn, each of our supervisors must possess the identical licensing requirement reserved for an owner of a company. As a result, more than 64% of our current field staff has college matriculation in fields such as Entomology, Urban Pest Management, and Biology. Some of our technicians had original careers in Agriculture, Forestry and Horticulture, and one was even a dental technician and another a chiropractor! Little wonder, then, that our management style is more horizontal than vertical, and that our supervisors are primarily involved behind the scenes in program design and consultation. The reality of all this is that each client is actually subject to a higher than industry-wide standard of supervision. In addition to a Manager, each of our Divisions has a separate Quality Control Supervisor whose sole responsibility is to monitor, inspect, supplement and teach. A standard technique they use is to select several customer locations each day, where they unobtrusively inspect the work and then make any corrections to the service or protocols if necessary. They frequently leave a calling card inside one of the rodent stations and instruct the technician to turn it in when it is discovered! Sneaky? Not really – just keeping everyone on his toes. But, all in all – as it took our clients to remind me – the strength of the company lies in the dignity, capabilities and professionalism of our technicians. Let’s just say that the rest of us here will endeavor to sustain that quality and ensure its continuum!