Towards a light-inducible two state permanent - igem

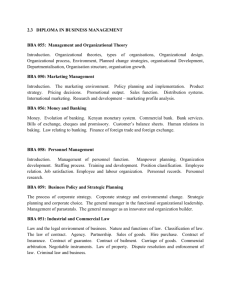

advertisement

Towards a light-inducible two state permanent differentiation program in E.coli. Chris Topher Tuttle V00197720 June 10, 2009 Introduction: Differentiation in multi-cellular organisms involves the development of different transcriptome and proteome libraries in cells derived from the same parent. Differentiation allows separate cells to preform separate functions, sharing a workload that would be too taxing or complex for a single cell. For example the cone cells in the retina all start out the same and grow up to a confluent lawn. They then differentiate into cells sensitive to short-, medium-, and long wavelength light. By following a spacial differentiation pattern different cell types are clustered, allowing trichromatic vision. Bacteria, being unicellular, have not evolved notable differentiation programs. However, an axenic lawn of E. coli could be thought of and treated as a single entity for the purposes of synthetic biology. Engineering a strain of E. coli capable of differentiating into two distinct cell types in a spacial manner is a step towards creating bacterial “tissues” capable of carrying out complex tasks. Unfortunately most of the proteins involved in eukaryotic differentiation programs are unlikely to function in E.coli, making the pursuit of self differentiating cells difficult. In 2006 the University of Austin developed a light sensor capable of tethering transcription at an operon to light exposure. They linked this sensor to pigment production, and created a camera. This did not involve differentiation of any cells, simply cells that were induced at different levels based on the light shining on them. When the light level is altered so is the expression of pigment. My idea is to extend the versatility of this camera to allow for permanent changes in gene expression after exposure to light. I suggest we create a cell line that contains two differentiation patterns. One of the differentiation patterns would be activated by light at 660nm and the other by exposure to xylose, a sugar. Cells stimulated by light would produce a recombinase which splices the xylose sensitive pathway out of the cell. These cells would then be committed to this first pathway. Cells that are exposed to xylose produce a different recombinase which splices the light sensitive pathway out of the cell. When a cell is exposed to one of these stimuli it becomes insensitive to the other stimulus. By first stimulating a plate of undifferentiated cells with a pattern of light we can create cell type 1 wherever it is required on the plate. Xylose exposure would then commit the remainder of the cells to type 2. This should leave us with a plate where any one cell is either type 1 or type 2, with the location of each cell type on the plate determined by which cells were initially stimulated by light. I propose that as outputs we use a red fluorescent protein to be produced by cell type 1 and a blue fluorescent protein produced by cell type two. In the undifferentiated state the cells would produce both red and blue fluorescent proteins. Cells differentiated to type 1 by light would stop producing blue colour. Residual blue colour will be degraded and the cells will turn solid red. Cells differentiated to type 2 by xylose will no longer produce red colour and will turn solid blue. The end product a plate of cells with each either blue or red, is effectively a two-colour image. By arranging the 'pixels' appropriately, with the aid of a red filter for one eye and a blue filter for the other eye, a 3D image could be rendered on the plate. This two state differentiation program would be a start towards engineering much more complex, multicomponent bacterial systems. Parts: Table 1. Parts required for the two stare differentiation system Biobrick registry number Function Bba_M30109 Light sensor generator device Bba_R0051 cI repressed promoter Bba_K137029 constitutive promoter Bba_J06505 LVA tagged mCherry Bba_B0034 Ribosome Binding site BBa_K112122 Cre recombinase Bba_I741005 XyIR coding sequence Bba_J31000 Hin recombinase Bba_B0015 double terminator. Bba_R0082 OmpR-P activated promoter Bba_C0051 CI coding sequence BBa_K100002 xylose/xyIR responsive promoter Bba_E0022 LVA tagged ECFP coding region Light sensor (state 1 differentiator) The Light Bright requires the light sensor/Env fusion protein developed at the University of Austin. This sensor requires accessory proteins for assembly. All parts needed to produce a functioning light sensor are provided as a device in the registry, part Bba_M30109. This device puts the accessory proteins under the control of a weaker promoter than the sensor protein, allowing for optimal activity. Unfortunately, only promoters inactivated by light are available in the registry, so an inverter must be used. A modified version of the lambda cI repressor will be used as the inverter. cI production (part BBa_C0051) is placed under the control of OmpR (part Bba_R0082) promoter, and lox production is put under control of the cI promoter, part Bba_R0051. In the dark, OmpR is phosphorylated and allows transcription of cI. cI binds to the cI promoter, repressing transcription of lox. When the cells are stimulated by light OmpR becomes dephosphorylated as the kinase domain of Cph8 is destabilized. This process shuts off production of cI, allowing the transcription of lox. Reporters ECFP, part Bba_E0022, excited at 439nm and emitting light at 476nm, and mCherry, part Bba_J06505, excited at 587nm and emitting light at 610nm will be used as reporters in this system. Both parts are LVA tagged for fast degradation, and are under the control of a constituitive promoter, part Bba_K137029. Xylose inducible PoPS generator (state 2 differentiator) An inducible promoter activated in the presence of a diffusable ligand is required to “develop” the non light-stimulated cells into cell Type 2. I chose the Xylose promoter for this task. XyIR, part Bba_I741005, binds Xylose then binds to the edited promoter BBa_K100002, initiating transcription. XyIr will be placed after the light sensor device, regulated by the same constitutive promoter type as the reporter genes. Terminator The terminator used at all sites in this system is device Bba_B0015. This consists of two terminators in tandem. This device has a 98.4% forward termination efficiency and a 29.5% reverse termination efficiency. Recombinases This system relies on two recombinases capable of removing DNA sequences located between their compatible recombination sequences. Recombination sequences composed of direct repeats result in DNA excision, sequences composed of inverted repeats result in inversion of the DNA fragment. Two such systems are available in the BioBrick registry. BBa_K112122 codes for Cre, capable of cutting DNA between Lox sites. Bba_J31000 codes for Hin, capable of cutting DNA between Hix sites. Parts BBa_J61046 and BBa_J44000 code for the Lox and Hix recombination sites respectively. Cloning the parts in their current orientation flanking the differentiation program should cause it to be excised cloning the parts in their current orientation upstream of the program and in inverted orientation downstream of the program should result in inversion of the DNA fragment in between. We want excision of the fragment, so cloning the parts in their normal orientation should achieve that. Hin is less efficient at excising DNA than it is at inverting it, so the Hin recombinase generator is put under the control of the 'development' ligand (xylose) instead of light to provide enough time to splice out DNA between the Hix sites. Table 3. Devices within the two state system. Device Constitutive parts Accessory protein generator M30109-K137029-B0034-I741005-B0015 Cph8 signal inverter R0082-B0034-C0051-B0015 cI repressed Cre generator R0051-B0034-K112122-B0015 Constituitive mCherry generator K137029-B0034-J06505-B0015 Constitutive ECFP generator K137029-B0034-E0022-B0015 Xylose induced Hin generator K100002-B0034-J31000-B0015 Assembly: All of the parts in this system are compliant with the RFC10 standard for biobrick assembly (http://partsregistry.org/Help:Assembly_standard_10). No in frame protein fusions are required in this system, as such RFC10 is robust enough for the entire assembly. RFC 10 involves adding one part at a time to a growing construct. Parts are flanked by EcoRI and XbaI cutting sites on the left and SpeI and PstI sites on the right. Assembly involves cutting the upstream part with EcoRI and SpeI to produce a fragment with E and S sticky ends. The downstream part and plasmid that will house the new parts is cut with EcoRI and XbaI, removing a fragment with E and X sticky ends and producing a plasmid with E and X sticky ends followed by the downstream part. Agarose gel electrophoresis followed by DNA extraction of the desired bands separates the E-S fragment from the junk plasmid, and the E-X plasmid/part from the junk insert. The E-S fragment and the E-X insert are combined in a ligation reaction, creating a circularized plasmid consisting of E-X prefix-upstream part-S/X hybrid scar-downstream part-S-P suffex. The resulting construct can be treated as a standard part for the purpose of the assembly. All parts required from the registry would be transformed into E.Coli on high copy number plasmids. Parts would be assembled, two at a time, towards the goal of three plasmids, each with a cassette assembled on it as laid out in Figure 3,. These constructs would then be moved to compatible low-medium copy number plasmids for operation of the system, and a single E.coli would be transformed with all three plasmids. The first plasmid contains the accessory proteins required for the circuit to function. These are the light sensor components, XyIR, and cI. Putting this plasmid in E. coli containing an OmpR controlled reporter would allow visualization of functionally transformed cells. The second plasmid contains the first differentiation program leading to red cells. E.coli containing this plasmid will produce Cre and mCherry, either of which can be used to report successful transformation with functional insert. The third plasmid contains the second differentiation program leading to blue cells. E.coli containing this plasmid will produce ECFP, again suitable as a reporter. It would be logical to assemble the parts first into devices as set out in Figures 1.0 and 1.1. This would allow us to submit each device back to the registry, and would provide flexibility to change specific promoters involved with each device if problems are encountered. Additionally, many of the devices in this system could be tested independently, allowing for a number of checkpoints as we progress towards a fully assembled system. Table 1.0. restriction sequences relevant to the RFC10 biobrick format. All parts compatible with RFC10 have been mutagenized to remove these sequences from within the part. Restriction enzyme Sequence cut Sequence after cleavage EcoRI 5'-GAATTC-3' 5'...G: :AATTC...3' XbaI 5'-TCTAGA-3' 5'...T: :CTAGA...3' SpeI 5'-ACTAGT-3' 5'...A: :CTAGT...3' PstI 5'CTGCAG-3' 5'...CTGCA: :G...3' NotI 5'GCGGCCGC-3' 5'...GC: :GGCCGC...3' Biobrick suffix 5'-Part-TACTAGTAGCGGCCG CTGCAG-3' Biobrick prefix for non coding 5'- parts GAATTCGCGGCCGCTTCTAGAGPart-3' Biobrick prefix for coding parts 5'-GAATTCGCGGCCGCT TCTAGPart-3' Method: Transfromations will take place in an envZ- strain of E.coli, part Bba_V1012 Cells will be rendered competent with the top10 protocol detailed by Tom Knight. Detailed protocol at http://openwetware.org/wiki/TOP10_chemically_competent_cells. Competent cells will be transformed based on the transformation protocol also set out by Tom Knight and available at http://openwetware.org/wiki/MIT_iGEM_Top10_ChemComp_Ecoli_transformation_protocol Plasmid DNA will be prepared from recycled silica Quigen columns. Purification protocol will be based on http://openwetware.org/wiki/Miniprep/Qiagen_kit Restriction digests will be preformed based on a modified version of the NEB protocol for the 3A antibiotic assembly http://www.neb.com/nebecomm/products/protocol445.asp. As both standard and 3A assembly are compatible with RCF10 parts, the same basic assembly steps outlined in this proposal can be ported to the 3A standard if the iGEM team prefers this method. Ligation protocol will be adopted from the NEB protocol available at http://www.neb.com/nebecomm/products/protocol446.asp. Length check PCR and sequencing steps will use VF2 (5'-TGCCACCTGACGTCTAAGAA-3') and VR (ATTACCGCCTTTGAGTGAGC) primers, complementary to the regions of the plasmids used that flank the insert. There are parts in the registry with internal sequences that VF2 or VR can bind to, producing extra bands of predictable size upon electrophoresis. Example: assembling the first plasmid of the system, pSB3C5 See Figure 7 for a graphical representation of this process. 1. Transform E. coli with each of the following rehydrated parts in pSB1A7 high copy number assembly plasmid with Amp resistance. Grow transformants overnight on Ampicillin enriched media, select a successful colony (or more than one if backups are prudent) and inoculate a tube of nutrient broth + ampicillin with it. Grow up overnight. Purify and length check the inserts. If length check passes freeze a sample of the E. coli containing the part and grow the appropriate number of aliquots of each part overnight, 1 aliquot for each instance of the part in the cassette to be assembled. Bba_M30109 – Light sensor generator device x1 Bba_K137029- constitutive promoter x2 Bba_B0034- Ribosome Binding site x2 Bba_I741005- XyIR coding sequence x1 Bba_B0015- double terminator. x2 Bba_R0082- OmpR activated promoter x1 Bba_C0051- cI coding sequence x1 2. Purify parts K137029, B0034(x2), and R0082 from E.coli using recycled spin columns. 3. Cut K137029 and R0082 with E and S and B0034 with E and X 4. Gel electrophoresis to remove the unwanted fragments (plasmid from the upstream part, insert from the downstream part) 5. Set up 2 ligation reactions with B0034 attached to linearized plasmid 6. To one reaction add K137029 fragment, to the other add R0082 fragment. 7. Transform E.Coli with ligated plasmids containing (K137029-B0034) and (R0082-B0034) 8. Grow up transformed E.coli overnight 9. purify (K137029-B0034) and (R0082-B0034) plasmids using recycled spin columns 10. PCR using VF2 and VR primers and compare length of amplicon to expected length for composite part. 11. Repeat 1-10 using I741005 and C0051 cut with E and S and B0015(x2) cut with E and X to create (I741005-B0015) and (C0051-B0015) 12. Repeat steps 1-10 using (K137029-B0034) cut with E and S and (I741005-B0015) cut with E and X to create (K137029-B0034-I741005-B0015) (only 1 ligation reaction) 13. Checkpoint: Sequence the insert. Device should generate XyIR. Test by moving device to a medium copy number plasmid pSB3C5 with cloramphenicol resistance containing a reporter under the control of Bba_K100002, the xylose sensitive promoter. Transform into E.coli, plate, add xylose, measure reporter concentration. 14. Repeat steps 1-10 using M30109 cut with E and S and (K137029-B0034-I741005-B0015) cut with E and X to create (M30109-K137029-B0034-I741005-B0015), the accessory protein generator. (one ligation reaction) 15. Sequencing checkpoint 16. Repeat steps 1-10 using (R0082-B0034) cut with E and S and (C0051-B0015) cut with E and X to create (R0082-B0034-C0051-B0015), the inverter. 17. Functional and sequencing checkpoints for the inverter using E.coli with GFP under control of a cI repressor. Absence of GFP indicates functional device. 18. Repeat steps 1-10 using (M30109-K137029-B0034-I741005-B0015) cut with E and S and (R0082-B0034-C0051-B0015) cut with E and X to create the final construct, (M30109-K137029B0034-I741005-B0015-R0082-B0034-C0051-B0015) 19. Purify pSB3C5 and (M30109-K137029-B0034-I741005-B0015-R0082-B0034-C0051-B0015) 20. Cut pSB3C5 and (M30109-K137029-B0034-I741005-B0015-R0082-B0034-C0051-B0015) with E and S in separate restriction digest reactions. 21. Gel electrophoresis to remove insert from pSB3C5 and remove plasmid from (M30109-K137029B0034-I741005-B0015-R0082-B0034-C0051-B0015) 22. Ligate purified pSB3C5 and (M30109-K137029-B0034-I741005-B0015-R0082-B0034-C0051B0015) 23. Transform into env- E. coli. Each plasmid would be assembled in the same manner. Whenever possible the devices should be tested, and re sequencing using VF2 and VR primers should happen with every 4-5 parts assembled as a minimum. When each of the devices are assembled individually, they should be combined using the same procedure, into the cassettes defined in Figure 3. Each cassette will then be moved to a different, lowmedium copy number plasmid pSB3C5 (P15A replicon), pSB4K5 (psc101 replicon), pSB6A1 (Pmb1 replicon) such that all three plasmids can co-exist within one cell and operate without draining to many system resources. Transforming E.coli containing the first plasmid with the second will prevent any “leakage” of Cre which could interfere with plasmid 3. E.coli containing plasmids 1 and 2 would glow red but would not produce Cre. Finally plasmid 3 would be added to E.coli containing plasmids 1 and 2. The final construct may have to be grown in the dark to prevent accidental “exposure” of the cells. Discussion: In this proposal I describe a strain of E. coli capable of undergoing a permanent differentiation into one of two cell types through induction with light at 660nm and development of the remaining cells with xylose. Spatial control of differentiation patterns is key to creating complex cellular machinery. Our system uses flourescent proteins as outputs but any program or circuit could be linked to each differentiation program provided it doesn't cross talk with any of the channels in the system (cI, Xylose, OmpR/envZ, Tet, arabinose [or specifically AraC production]). Additionally, many of those channels provide locations to “jack in” to the device and alter it's function. Differentiating, for example, cells into energy producers and energy consumers arranged spatially to provide optimum nourishment of the consumers would allow workload sharing for more energy intensive tasks. Even merely with fluorescent outputs the system lends itself to more than just image creation. Setting red cells to 0 and blue cells to 1 would allow a plate of E. coli to be used as a single-write data storage device. This system is scalable to allow for more differentiation patterns. Specifically the maximum number of differentiation patterns is dependent on the number of distinct recombinase systems and light sensor/promoter combinations. The registry currently only has one light sensor, but that number is sure to expand. Hopefully future light sensors will not all be coupled to EnvZ, as a distinct promoter would be needed for each sensor to function in parallel in the same cell. Several recombinase systems exist to varying degrees of completion in the registry. I suggest that an attempt be made to expand the Cre/Lox family of recombinases through mutagenesis to create an array of distinct but similar recombinases which favour excision of DNA. Using two light sensors and three recombinase systems a three state differentiation system could be constructed. Linking the states to red, green, and blue fluorescent protein outputs would allow for the spacial arrangement of these cell types in clusters in an image format. Such an arrangement could be used as a full colour display, especially suited to still images at high resolution, driven by fluorescent beams at each excitation frequency. The kinase region of the cph8 fusion protein created by the University of Austin destabilizes in the presence of light and is stable and functioning in the absence of light. Therefore when combined with promoters that are active in the presence of phosphorylated OmpR, most systems using the light sensor require an inverter for the desired effect. A promoter that was repressed in the presence of phosphorylated OmpR and activated in its absence would eliminate the additional complexity of inverters, as well as some potential cross-talk areas. One potential failing of the Light bright system as implemented in this proposal is that, until development with xylose, the cells would be sensitive to ambient light. A solution to the sensitivity issue might be to put a temperature sensitive cI variant under the control of a constitutive promoter. The cells could be grown and handled at 30 degrees Celsius, where the constitutively expressed cI would prevent cre transcription even if light causes dephosphorylation of cph8 and OmpR and a drop in regulated cI transcription. The etching chamber with the laser and the xylose distributor could be kept at 42 degrees Celsius. At this temperature the constitutively expressed cI would be destabilized, allowing light stimulus to differentiate the cells. one potential problem with this system is if the cI promoter is being repressed mostly by temperature sensitive cI then a dramatic change in temperature could induce transcription before the stable, OmpR controlled cI can bind the promoter. Gradual temperature increases may overcome this problem if it occurs. The composite device in the Biobricks registry for generating functional cph8 has been problematic for the last few years of iGEM. Recreating that device might be not only beneficial to this project, but to future iGEM teams. Additionally, reengineering the device to no longer use the tet and pBad promoters would free those pathways up for use elswhere in the system (tet would make a good inverter instead of cI, as it is less leaky). Using weaker constituitive promoters and weak ribosome binding sites for the accessory proteins and a stronger promoter/rbs for cph8 should be as effective as using the tet and pBad promoters without inducers as is proposed for the current device. The E. coli light bright is a first step towards engineering cells capable of stable, spatially definable differentiation. As described there are still some limitations preventing elegant function of the circuitry, but it should suffice as a proof of concept for recombinase mediated light inducible differentiation.