LakshmananV_1012_eps - Heriot

advertisement

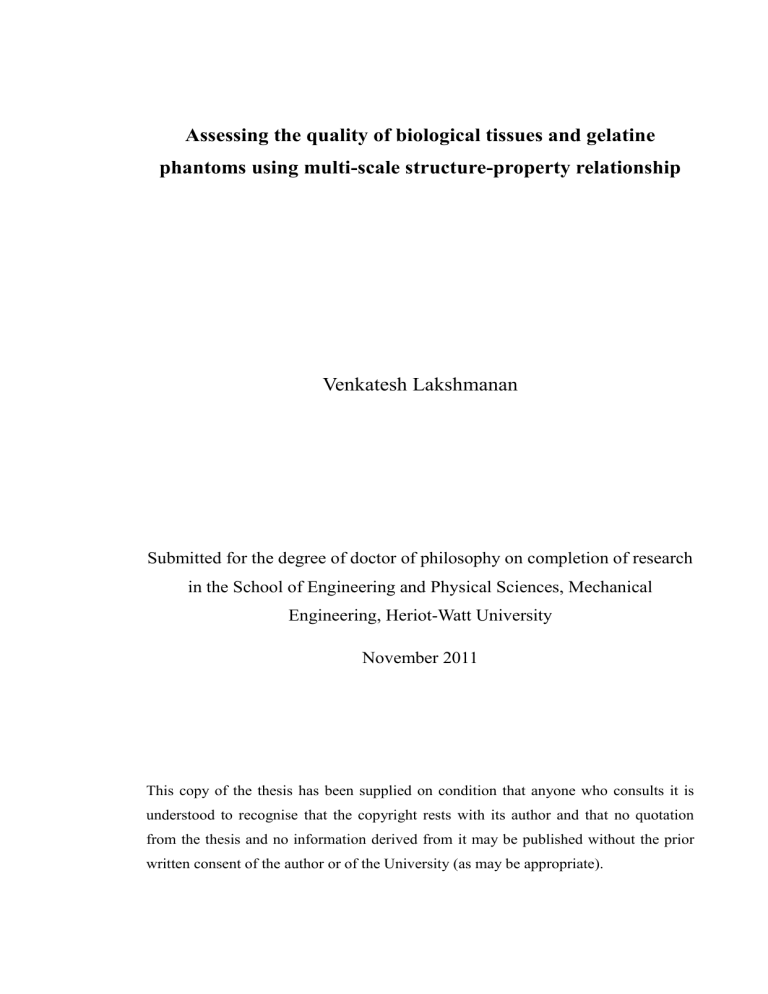

Assessing the quality of biological tissues and gelatine phantoms using multi-scale structure-property relationship Venkatesh Lakshmanan Submitted for the degree of doctor of philosophy on completion of research in the School of Engineering and Physical Sciences, Mechanical Engineering, Heriot-Watt University November 2011 This copy of the thesis has been supplied on condition that anyone who consults it is understood to recognise that the copyright rests with its author and that no quotation from the thesis and no information derived from it may be published without the prior written consent of the author or of the University (as may be appropriate). Abstract The main aim of this work is to develop methods of assessing soft biological tissue quality using structure-property relationships. “Tissue quality” is here taken to mean the condition of the biological tissue structure which can be quantified in terms of features at a range of scales, including histological features. The purpose is to serve as a diagnostic aid in clinics and provide quantitative information that might replace the more traditional palpation. It is recognised that any structure-property relationship may be local to particular areas and may be differently expressed at a range of scales of probe size. In order to arrive at some generic outcomes, two model systems were chosen, one a biological mimic (gelatin-oil mixtures) which had the advantage that certain aspects of the structure could be varied. The biological system was chosen to be ovine connective tissue (collagen-lipid mixture) because it was expected to be similar in its components to the mimic, although with a more natural variation in structure. Static and dynamic indentation tests were carried out on all of the material and the static and dynamic elastic and viscoelastic properties were determined. Two experimental rigs were developed, a macro-scale one with a 0.5mm radius indenter and micro-scale one with a, pyramidal indenter of base side 4µm, height 6µm and opening angle 70 . The macro-scale rig was purpose-built with indentation distance being controlled using software specifically configured for the work. The macro-scale rig was a modified atomic force microscope with a piezo-ceramic actuator being used to vibrate the specimen stage. Experiments were carried out under displacement control, with the mean indentation distance in the range from 1-4% of the specimen height, a frequency range of 1-10Hz and an indentation displacement amplitude of 30 and 90µm. Nine different oil in gelatine formulations were used and the ovine biological tissue was classified as; collagen (from the ligamentum nuchae), fat (from the tail) and a collagenfat mixture (from the abdomen). The dynamic tests were carried out over a range of frequency and the variation of the loss and storage modulus with frequency was used to arrive at an appropriate viscoelastic model for each of gelatine-oil and biological tissue systems. Finally, the elastic and viscous moduli were correlated with tissue quality (structure) to obtain the structure-property relationship. Of the various three-parameter visco-elastic models tested, a Maxwell model in parallel with a spring was found to be the most suitable for the biological tissues whereas a Kelvin model in series with a spring was best for the gelatine-oil mixtures. Using the resulting visco-elastic moduli, it was found that a structure-property relationship exists for biological tissues and gelatine phantoms at both scales. Furthermore, the results suggest that the scale of the probe affects the dynamic mechanical properties for the biological tissues but not for the gelatine phantoms. This work is dedicated to my beloved parents Lakshmanan sangapillai, Rajathi Lakshmanan, my lovely wife Usha Venkatesh, and to my adorable little sister Shalini Rajesh. Acknowledgements Many hardships have been overcome and lot of hard work has gone in to completion of this work. I would like to thank every individual of Mechanical Engineering department, Heriot-Watt University who had directly or indirectly aided in completion of this thesis. I would like to thank the School of EPS, Heriot-Watt University for providing scholarship for my studies. First and foremost, my sincere thanks goes to my PhD supervisor Professor R. (Bob) L. Reuben as he offered unparallel support, guidance, wisdom and encouragement through out this study. I also would like to extend my gratitude to Dr. T.H.J. Yang for his support and guidance at the early stages of this study and to Ms. Marian Millar for her dedicated training and support with the Atomic Force Microscopy. Thanks to my parents, my wife, my family members and friends, who motivated me to complete this research study with their devoted moral support and love. My special thanks and appreciation goes to the admin staff Mrs. A. Blyth, Mrs. M. Thomson, Mrs. Josie, Mrs A Campbell, Mrs. J Suttie, Mrs. I Fox, Mrs. R. Crawford, the IT staff Mr. John Pritchard, Mr. Aftab Aziz, Mr. Paul Glynn and the workshop staff of Mechanical and Electrical Engineering, Mr. A. Buchan, Mr. R. Kinsella, Mr K. Caruthers, Mr. C. Smith, Mr. A. Huston, Mr. P. Dampster and my office colleagues who have made my time in the school memorable and enjoyable. ACADEMIC REGISTRY Research Thesis Submission Name: Venkatesh Lakshmanan School/PGI: School of Engineering and Physical Sciences Version: First (i.e. First, Resubmission, Final) Degree Sought (Award and Subject area) PhD Mechanical Engineering Declaration In accordance with the appropriate regulations I hereby submit my thesis and I declare that: 1) 2) 3) 4) 5) * the thesis embodies the results of my own work and has been composed by myself where appropriate, I have made acknowledgement of the work of others and have made reference to work carried out in collaboration with other persons the thesis is the correct version of the thesis for submission and is the same version as any electronic versions submitted*. my thesis for the award referred to, deposited in the Heriot-Watt University Library, should be made available for loan or photocopying and be available via the Institutional Repository, subject to such conditions as the Librarian may require I understand that as a student of the University I am required to abide by the Regulations of the University and to conform to its discipline. Please note that it is the responsibility of the candidate to ensure that the correct version of the thesis is submitted. Signature of Candidate: Date: Submission Submitted By (name in capitals): VENKATESH LAKSHMANAN Signature of Individual Submitting: Date Submitted: For Completion in the Student Service Centre (SSC) Received in the SSC by (name in capitals): 1.1 Method of Submission (Handed in to SSC; posted through internal/external mail): 1.2 E-thesis Submitted (mandatory for final theses) Signature: Date: Table of Contents CHAPTER 1 ............................................................................................................................................... 1 INTRODUCTION ...................................................................................................................................... 1 1.1 1.2 1.3 1.4 1.5 1.6 OVERVIEW .................................................................................................................................... 1 BACKGROUND ............................................................................................................................... 1 MULTI-SCALE STRUCTURE-PROPERTY RELATIONSHIPS ................................................................. 2 TISSUE MODEL SYSTEM ................................................................................................................. 3 RESEARCH OBJECTIVES ................................................................................................................. 4 THESIS STRUCTURE ....................................................................................................................... 5 CHAPTER 2 ............................................................................................................................................... 8 LITERATURE REVIEW .......................................................................................................................... 8 2.1 STRUCTURE-PROPERTY RELATIONSHIPS IN BIOLOGICAL MATERIALS............................................. 8 2.2 MECHANICAL TESTING OF BIOLOGICAL MATERIALS .................................................................... 10 2.2.1 Test conditions.................................................................................................................... 11 2.2.2 Tension ............................................................................................................................... 13 2.2.3 Shear .................................................................................................................................. 14 2.2.4 Impact ................................................................................................................................. 15 2.2.5 Compression ....................................................................................................................... 15 2.2.6 Indentation ......................................................................................................................... 17 2.3 MECHANICAL PROPERTIES OF BIOLOGICAL MATERIALS .............................................................. 19 2.3.1 Tissue structural proteins and its properties ...................................................................... 22 2.3.2 Mechanical properties of engineered tissue-mimics .......................................................... 23 2.3.2.1 Mechanical behaviour of gelatine ..................................................................................................24 2.4 MICRO-SCALE MECHANICAL TESTING OF BIOLOGICAL MATERIALS ............................................. 26 2.4.1 AFM-principles and measurements .................................................................................... 26 2.4.2 AFM imaging and mechanical properties .......................................................................... 29 2.5 SUMMARY AND IDENTIFICATION OF THESIS TOPIC....................................................................... 32 CHAPTER 3 ............................................................................................................................................. 33 MATERIALS AND METHODS............................................................................................................. 33 3.1 SAMPLES ..................................................................................................................................... 33 3.2 MACRO-SCALE TESTING .............................................................................................................. 35 3.2.1 Macro-scale test rig............................................................................................................ 35 3.2.2 Macro-scale data acquisition, control and software development ..................................... 39 3.2.3 Macro-scale experimental procedure ................................................................................. 43 3.3.3.1 3.2.3.2 Preliminary calibration experiments ..............................................................................................44 Systematic testing (Biological tissues and Gelatine+oil mimic): ...................................................47 3.3 MICRO-SCALE TESTING ............................................................................................................... 49 3.3.1 Micro-scale test rig ............................................................................................................ 49 3.3.2 Micro-scale test rig calibration .......................................................................................... 51 3.3.2.1 3.3.3 3.3.3.1 3.3.3.2 3.3.3.3 3.4 Calibration standards and distinguishability ..................................................................................56 Micro-scale experimental procedure.................................................................................. 58 Repeatability and ageing ................................................................................................................58 Systematic testing of gelatine formulations ...................................................................................59 Determining variability of biological tissues .................................................................................60 SUMMARY OF EXPERIMENTS ....................................................................................................... 60 CHAPTER 4 ............................................................................................................................................. 62 RESULTS OF EXPERIMENTS ............................................................................................................. 62 4.1 MACRO-SCALE EXPERIMENTAL RESULTS .................................................................................... 62 4.1.1 Systematic Testing (gelatine based formulations) .............................................................. 62 4.1.2 Systematic Testing (Ovine biological tissues) .................................................................... 66 4.2 MICRO-SCALE RESULTS ............................................................................................................... 72 4.2.1 Gelatine formulations ......................................................................................................... 73 4.2.2 Biological tissues ................................................................................................................ 74 4.3 MICRO STRUCTURAL MEASUREMENTS ........................................................................................ 75 4.3.1 Gelatine formulations ......................................................................................................... 75 4.3.2 Histology of biological tissues............................................................................................ 76 CHAPTER 5 ............................................................................................................................................. 78 ANALYSIS OF RESULTS ...................................................................................................................... 78 5.1 STATISTICAL ANALYSIS ............................................................................................................... 78 5.1.1 Analysis of macro-scale experimental results .................................................................... 78 5.1.2 Statistical analysis of micro-scale experimental results ..................................................... 82 5.2 CONSTITUTIVE MATHEMATICAL MODELLING .............................................................................. 83 5.2.1 Non-linear regression analysis (curve fitting of experimental results) .............................. 91 CHAPTER 6 ............................................................................................................................................. 96 DISCUSSION ........................................................................................................................................... 96 6.1 EFFECTIVENESS OF MECHANICAL TESTING METHODS .................................................................. 96 6.2 MECHANICAL PROPERTIES OF BIOLOGICAL TISSUES AND GELATINE PHANTOMS.......................... 98 6.2.1 Gelatine formulations ......................................................................................................... 98 6.2.2 Biological tissues .............................................................................................................. 107 6.3 SCALE EFFECTS ......................................................................................................................... 111 6.4 STRUCTURE-PROPERTY RELATIONSHIP ...................................................................................... 123 6.4.1 Gelatine formulations ....................................................................................................... 124 6.4.2 Biological tissues .............................................................................................................. 128 CHAPTER 7 ........................................................................................................................................... 130 CONCLUSIONS AND RECOMMENDATIONS ............................................................................... 130 7.1 7.2 7.3 7.4 7.5 7.6 CONCLUSIONS ON MECHANICAL TESTING METHOD: .................................................................. 130 CONCLUSIONS ON MECHANICAL PROPERTIES: ........................................................................... 130 CONCLUSIONS ON STRUCTURE-PROPERTY RELATIONSHIPS: ...................................................... 132 CONCLUSIONS ON MULTI-SCALE EFFECTS ARE SUMMARISED AS FOLLOWS: .............................. 132 CONCLUSIONS ON CLINICAL APPLICABILITY: ............................................................................ 133 RECOMMENDATIONS FOR FUTURE WORK .................................................................................. 133 REFERENCES ....................................................................................................................................... 135 DERIVATION OF CONSTITUTIVE DIFFERENTIAL EQUATIONS FOR VISCOELASTIC MODELS ................................................................................................................................................ 150 RESULTS OF PRELIMINARY EXPERIMENTS, MACRO-SCALE ............................................. 155 Lists of Figures FIGURE 1.1: BLOCK DIAGRAM SHOWING TISSUE MODEL SYSTEM. ................................................................ 4 FIGURE 1.2: SUMMARY OF MEASURED QUASI-STATIC AND DYNAMIC MODULI OF BIOLOGICAL TISSUES. ( DATA FROM FUNG, 1981, 1993; KROUSKOP ET AL ., 1998; CARLTON ET AL. 1962; GOSLINE ET AL. 1979; MIJAILOVICH ET AL. 1994; STROMBERG ET AL. 1969; PARKER ET AL. 1993). BARS INDICATE THE GENERAL RANGES OF MECHANICAL PROPERTY GROUPED BY BIOLOGICAL TISSUE TYPE. ....................... 4 FIGURE 1.3: BLOCK DIAGRAM ILLUSTRATING GENERAL STUDY FLOW. ........................................................ 6 FIGURE 2.1: MULTI-SCALE STRUCTURE OF TENDON (BAER ET AL. 1991)...................................................... 9 FIGURE 2.2: RANGE OF MEASURED MECHANICAL PROPERTIES OF BIOLOGICAL MATERIALS FROM LITERATURE AS COLLECTED BY SARVAZYAN ET AL. (1998) WITH REPORTED SHEAR MODULUS (G) MODIFIED TO YOUNG’S MODULUS (E) USING E=3G, ASSUMING POISSON’S RATIO TO BE 0.5. ............. 20 FIGURE 2.3: ELECTRON MICROGRAPH OF COLLAGEN FIBRE EXTRACTED FROM RAT-TAIL TAKEN SHOWN THE PERIODIC ARRANGEMENT OF TROPOCOLLAGEN SUBUNITS. (WARD, 1977) ................................... 23 FIGURE 2.4: SCHEMATIC ILLUSTRATION OF PRINCIPLE OF OPERATION OF AFM. ........................................ 27 FIGURE 2.5: MICRO MECHANICS INVOLVED IN FORCE-DISTANCE TRACE AND VARIOUS STAGES ASSUMED BY AFM TIP (POSITIONS A-E) DURING CONTACT-MODE AFM MEASUREMENT ARE EXPLAINED (TRACE SHOWS THE APPROACH (RED LINE) AND RETRACTION (YELLOW LINE) OF THE CANTILEVER WITH RESPECT TO THE SAMPLE. .................................................................................................................... 28 FIGURE 2.6: A) MECHANICAL MODEL OF AFM TIP-SAMPLE SYSTEM (HUTTER AND BECHHOEFER, (1993)) IN WHICH A SPHERICAL INDENTER OF RADIUS R IS MOUNTED TO A SPRING WITH SPRING CONSTANT K, IS THE DEFLECTION CAUSED DUE TO TIP-SAMPLE INTERACTION, Z IS A RESTING POINT IN HEIGHT AT WHICH THERE IS NO DEFLECTION AND D IS THE DISTANCE BETWEEN SAMPLE PLANE AND THE INDENTER. B) MICRO-CANTILEVER MADE FROM SILICON NITRIDE, INSET HIGHLIGHTING THE PYRAMIDAL TIP). ................................................................................................................................. 29 FIGURE 2.7: LOGARITHMIC PLOT OF PUBLISHED YOUNG’S MODULUS, OBTAINED FROM LITERATURE, OF BIOLOGICAL (DNA, BACTERIAL & FUNGAL CELLS, VIRUS, BIO-FIBERS, VESICLES, CELLS FROM CONNECTIVE TISSUES, TENOCYTES, PLATELETS, FIBROBLASTS, CARTILAGE) AND NON-BIOLOGICAL (METALS, RUBBER, GELS LIKE GELATINE) MATERIALS MEASURED AT THE MICRO-SCALE USING AFM AND OTHER SIMILAR MICRO-SCALE TECHNIQUES. ............................................................................... 31 FIGURE 3.1:TRANSMISSION MICROGRAPH OF FORMULATION-3 (TABLE 3.1). THE SAMPLE THICKNESS WAS APPROXIMATELY 20µM. ...................................................................................................................... 34 FIGURE 3.2: TRANSMISSION MICROGRAPH OF FORMULATION-7 (TABLE 3.1). THE SAMPLE THICKNESS WAS APPROXIMATELY 20µM. ...................................................................................................................... 34 FIGURE 3.3: PACKAGING OF SOFT (ABDOMEN) TISSUE. .............................................................................. 35 FIGURE 3.4: OVINE LIGAMENTUM NUCHAE BULK MATERIAL, AS HARVESTED, ALONGSIDE OF 1CM 1CM 1CM SAMPLE. ...................................................................................................................................... 35 FIGURE 3.5: DIAGRAMMATIC ILLUSTRATION OF DESIGN OF MACRO-SCALE RIG. LEGEND:1) PROXIMITY PROBE, 2) BRASS THREADED ADAPTER, 3) THREADED HOLE FOR M4 CRUB SCREW, 4) SLIDING FIT OF PROBE IN TO BRASS, 5) THREADED PITCH, 1.25-1.5MM, 6) STEPPER MOTOR ACTUATOR, 7) FORCE FITTED BRASS BUSH TO AVOID WOBBLING OF INDENTER, 8) INDENTER SCREWED ON TO THE ACTUATOR ROD, 9) PROBE MOUNTING BLOCK, 10) PROBE MOUNTING BLOCK CAPABLE TO VERTICAL ADJUSTMENT, 11) 25MM PILLAR-1, 12) HORIZONTAL ADJUSTMENT SLOT, 13) WIRE CONNECTIONS, 14) PROXIMITY SENSOR SETUP, 15) PROBE SENSING SURFACE, 16) 25MM PILLAR-2, 17) MOUNTINGS FOR FORCE SENSOR, 18) SLOT FOR THE ACTUATOR CARRYING THE INDENTER, 19) SLOT FOR PROXIMITY PROBE, 20) PLATFORM FOR TEST SAMPLE, 21) FORCE SENSOR, 22) 25MM PILLAR, 23) MOUNTING RINGS, 24) BASE PLATE ‘U’ CHANNEL AND 25) CAP SCREW. .......................................................................... 37 FIGURE 3.6: CALIBRATION PLOTS OF FORCE SENSOR USING STANDARD WEIGHTS, A) I AND B) II WITH AMPLIFIER. .......................................................................................................................................... 38 FIGURE 3.7: CALIBRATION PLOTS FOR PROXIMITY SENSOR A) PLOT SHOWING DATA POINTS OF CALIBRATION-I & II B) LINEAR FITS FOR CALIBRATION DATA I & II. ................................................. 38 FIGURE 3.8: SUMMARY OF FUNCTIONALITY OF CONTROL PROGRAMME, A) SCREEN SHOT OF USER INTERFACE. B) FLOW CHART ILLUSTRATING SEQUENTIAL CONTROL ALGORITHM. C) BLOCK DIAGRAM ILLUSTRATING CONTROL LOOP IN A TYPICAL SYSTEMATIC TEST EXPERIMENT. D) TYPICAL RAW EXPERIMENTAL RESULT AT 1 HZ. ........................................................................................................ 40 FIGURE 3.9: DATA PROCESSING PROGRAM FLOW DIAGRAM. ...................................................................... 41 FIGURE 3.10: A) RAW DATA, UNPROCESSED, B) RAW DATA, ZEROED, C) NOISE FILTERED FORCE, D) NOISE FILTERED DISPLACEMENT, E) SIGNAL AVERAGED FORCE, AND F) SIGNAL AVERAGED DISPLACEMENT. ............................................................................................................................................................ 42 FIGURE 3.11: DIAGRAMMATIC ILLUSTRATION OF OVERALL MACRO-SCALE EXPERIMENTAL SETUP WITH A PHOTOGRAPH OF FULLY COMMISSIONED MACRO-SCALE RIG. .............................................................. 44 FIGURE 3.12: SCHEMATIC ILLUSTRATING THE DYNAMIC INDENTATION TESTS THAT WERE CARRIED OUT ON THE POINTS 1 TO 12 AT FOUR MEAN DISPLACEMENTS (M1, M2, M3 AND M4) AT CONSTANT AMPLITUDE OF A1. .............................................................................................................................. 46 FIGURE 3.13: EXPERIMENT I SHOWING APPROXIMATE POSITIONS OF TEST POINTS 1-12 ON THE SAMPLE SURFACE. ............................................................................................................................................ 46 FIGURE 3.14: EXPERIMENT II SHOWING APPROXIMATE POSITIONS OF TEST POINTS 1-16 ON THE SAMPLE SURFACE. ............................................................................................................................................ 47 FIGURE 3.15: SCHEMATIC ILLUSTRATING THE SYSTEMATIC TESTS THAT WERE CARRIED OUT ON THE POINTS 1 TO 16 ON THE SAMPLE SURFACE AT TWO AMPLITUDES (A1 AND A2) AND TWO MEAN DISPLACEMENTS (M1 AND M2). .................................................................................................................................... 48 FIGURE 3.16: A) DESIGN DIAGRAM OF TOP PLATE. B) BOTTOM PLATE. C) MICRO-SCALE RIG FINAL ASSEMBLY WITH PIEZO ACTUATOR. D) MULTI LAYER PIEZO ACTUATOR. ............................................ 49 FIGURE 3.17: INCORPORATION OF VIBRATING STAGE IN AFM. .................................................................. 50 FIGURE 3.18: OVERALL MICRO-SCALE EXPERIMENTAL SETUP USING AFM. .............................................. 51 FIGURE 3.19: A) IDEAL NA/NM CALIBRATION CURVE FROM SPRING CONSTANT CALIBRATION EXPERIMENT. B) NA/NM CALIBRATION CURVE OBTAINED IN THIS STUDY AND LINEAR FIT. C) CALIBRATION CURVE FOR DISPLACEMENT OF MICRO-SCALE RIG FOR VARIOUS INPUT VOLTAGES FROM THE PIEZO PULSER CONTROL UNIT TO THE PIEZO ELECTRIC ACTUATOR. D) RAW INPUT PULSE TO MICRO-SCALE RIG AT 2.5HZ. E) OUTPUT AFM CANTILEVER DEFLECTION IN RAW VDAC READ EXTERNALLY FROM OUT-2 PORT OF EDU AT 2.5HZ. F) OUTPUT AFM CANTILEVER DEFLECTION IN RAW NA ACQUIRED INTERNALLY BY AFM CONTROL SOFTWARE FROM MANUFACTURER. ................................................. 52 FIGURE 3.20: EXAMPLE. Z-MOTOR CALIBRATION PLOT OF 5V JOG APPROACH (DOWN). ............................. 54 FIGURE 3.21: AFM CANTILEVER DEFLECTION DURING APPOACH-RETRACTION INVESTIGATION. ............... 54 FIGURE 3.22: PLOT OF FORCE AMPLITUDE DURING JOG APPROACH FOR 15NM (50V) SAMPLE VIBRATION AMPLITUDE. ........................................................................................................................................ 56 FIGURE 3.23: PLOT OF FORCE AMPLITUDE DURING JOG APPROACH FOR 60NM (200V) SAMPLE VIBRATION AMPLITUDE. ........................................................................................................................................ 56 FIGURE 3.24: AMPLITUDE RATIO IN KPA FOR SAMPLES OF DIFFERENT HARDNESS, MEASURED WITH VARIOUS INPUT AMPLITUDES AT A) 2.5 HZ, B) 10HZ AND PD IN RADIANS FOR THE SAME MEASURED AT C) 2.5 HZ, D) 10HZ. ............................................................................................................................. 57 FIGURE 3.25: RESULTS OF REPEATABILITY EXPERIMENT ON GELATINE FORMULATION ON ALL FOUR DAYS SHOWING A) AMPLITUDE RATIO (AR) AND B) PHASE DIFFERENCE (PD) PLOTS. .................................. 59 FIGURE 4.1: MACRO-SCALE GEL FORMULATION RESULTS, AMPLITUDE RATIO (AR), DAY-1. ................... 63 FIGURE 4.2: MACRO-SCALE GEL FORMULATION RESULTS, AMPLITUDE RATIO (AR), DAY-4. ................... 63 FIGURE 4.3: MACRO-SCALE GEL FORMULATION RESULTS, PHASE DIFFERENCE (PD), DAY-1. ................... 64 FIGURE 4.4: MACRO-SCALE GEL FORMULATION RESULTS, PHASE DIFFERENCE (PD), DAY-4. ................... 64 FIGURE 4.5: MACRO-SCALE GEL FORMULATION RESULTS, MEAN RATIO (MR), DAY-1. ............................ 65 FIGURE 4.6: MACRO-SCALE GEL FORMULATION RESULTS, MEAN RATIO (MR), DAY-4. ............................ 65 FIGURE 4.7: OVINE BIOLOGICAL TISSUE RESULTS. AMPLITUDE RATIO (AR), DAY 1. ................................. 67 FIGURE 4.8: OVINE BIOLOGICAL TISSUE RESULTS. AMPLITUDE RATIO (AR), DAY 4. ................................. 67 FIGURE 4.9: OVINE BIOLOGICAL TISSUE RESULTS. PHASE DIFFERENCE (PD), DAY 1. ................................ 68 FIGURE 4.10: OVINE BIOLOGICAL TISSUE RESULTS. PHASE DIFFERENCE (PD), DAY 4. .............................. 68 FIGURE 4.11: OVINE BIOLOGICAL TISSUES RESULTS. MEAN RATIO (MR), DAY 1. ..................................... 69 FIGURE 4.12: OVINE BIOLOGICAL TISSUE RESULTS. MEAN RATIO (MR), DAY 4........................................ 69 FIGURE 4.13: EXTENDED OVINE BIOLOGICAL TISSUE RESULTS. AMPLITUDE RATIO (AR), DAY-1. ............ 70 FIGURE 4.14: EXTENDED OVINE BIOLOGICAL TISSUE RESULTS. AMPLITUDE RATIO (AR), DAY-4. ............ 70 FIGURE 4.15: EXTENDED OVINE BIOLOGICAL TISSUE RESULTS. PHASE DIFFERENCE (PD), DAY 1. ............ 71 FIGURE 4.16: EXTENDED OVINE BIOLOGICAL TISSUE RESULTS. PHASE DIFFERENCE (PD), DAY 4. ............ 71 FIGURE 4.17: EXTENDED OVINE BIOLOGICAL TISSUE RESULTS. MEAN RATIO (MR), DAY-1. .................... 72 FIGURE 4.18: EXTENDED OVINE BIOLOGICAL TISSUE RESULTS. MEAN RATIO (MR), DAY-4. .................... 72 FIGURE 4.19: MICRO-SCALE AR MEASUREMENTS ON GELATINE. .............................................................. 73 FIGURE 4.20: MICRO-SCALE PD MEASUREMENTS ON GELATINE. ............................................................... 74 FIGURE 4.21: EXPERIMENT I, AR, OVINE BIOLOGICAL TISSUES.................................................................. 74 FIGURE 4.22: EXPERIMENT I, PD, OVINE BIOLOGICAL TISSUES. ................................................................. 74 FIGURE 4.23: TRANSMISSION MICROGRAPH OF SLICE OF GELATINE FORMULATION-1 (11.4G/100ML GEL+30ML OIL) SHOWING MEASURED OIL POCKET DIAMETER............................................................. 75 FIGURE 4.24: TRANSMISSION MICROGRAPH OF SLICE OF GELATINE FORMULATION-3 (11.4G/100ML GEL+50ML OIL) SHOWING MEASURED OIL POCKET DIAMETER............................................................. 75 FIGURE 4.25: TRANSMISSION MICROGRAPH OF SLICE OF GELATINE FORMULATION-7 (17.4G/100ML GEL+30ML OIL) SHOWING MEASURED OIL POCKET DIAMETER............................................................. 75 FIGURE 4.26: TRANSMISSION MICROGRAPH OF SLICE OF GELATINE FORMULATION-9 (17.4G/100ML GEL+50ML OIL) SHOWING MEASURED OIL POCKET DIAMETER............................................................. 75 FIGURE 4.27: HISTOGRAM SHOWING THE MORPHOLOGICAL DISTRIBUTION OF OIL POCKETS IN GELATINE PHANTOMS AND LIPID PACKETS IN OVINE BIOLOGICAL TISSUE IN TERMS OF THE RADIUS OF THE PACKETS MEASURED. .......................................................................................................................... 76 FIGURE 4.28: HISTOLOGICAL MICROGRAPH OF OVINE LIGAMENTUM NUCHAE TISSUE (100% COLLAGEN). . 77 FIGURE 4.29: HISTOLOGICAL MICROGRAPH OF OVINE POPLITEAL FAT TISSUE. (100% FAT). ...................... 77 FIGURE 4.30: EXAMPLE OF LIPID POCKET MEASUREMENT FOR OVINE POPLITEAL FAT TISSUE. ................... 77 FIGURE 4.31: HISTOLOGICAL MICROGRAPH OF ABDOMEN/FLANK TISSUE (COLLAGEN+FAT). .................... 77 FIGURE 4.32: EXAMPLE OF LIPID PACKET MEASUREMENT OF OVINE FLANK TISSUE FROM ABDOMEN. ....... 77 FIGURE 4.33: HISTOGRAM SHOWING THE MORPHOLOGICAL DISTRIBUTION OF FAT GLOBULES IN OVINE POPLITEAL FAT AND ABDOMEN. .......................................................................................................... 77 FIGURE 5.1: MICRO-SCALE, EXPERIMENT-I, HISTOGRAMS OF A) AR AND B) PD FOR GROUPS OF TISSUE TYPE. ................................................................................................................................................... 83 FIGURE 5.2: ONE OF THE 3-PARAMETER VISCO-ELASTIC MODELS (MODEL 6) WITH ILLUSTRATIONS OF INDIVIDUAL AND TOTAL STRESS, STRAIN COMPONENTS. ..................................................................... 85 FIGURE 5.3: PD VS. DIMENSIONLESS FREQUENCY FOR MODEL 3 FOR VARIOUS VALUES OF E 2 / E1 . ......... 88 FIGURE 5.4: PD VS. DIMENSIONLESS FREQUENCY FOR MODEL 4 FOR VARIOUS VALUES OF 1 /2 . .......... 88 FIGURE 5.5: PD VS. DIMENSIONLESS FREQUENCY FOR MODEL 5 FOR VARIOUS VALUES OF 1 . ................. 89 FIGURE 5.6: PD VS. DIMENSIONLESS FREQUENCY FOR MODEL 6 FOR VARIOUS VALUES OF 1 /2 RATIO WITH 1 MAINTAINED CONSTANT. ....................................................................................................... 89 FIGURE 5.7: PD VS. DIMENSIONLESS FREQUENCY FOR MODEL 6 FOR VARIOUS VALUES OF 1 /2 RATIO WITH 2 MAINTAINED CONSTANT. ..................................................................................................... 89 FIGURE 5.8: DIMENSIONLESS AR VS. DIMENSIONLESS FREQUENCY FOR MODEL 3 FOR LOWER VALUES OF E2 / E1 ................................................................................................................................................ 89 FIGURE 5.9:DIMENSIONLESS AR VS. DIMENSIONLESS FREQUENCY FOR MODEL 3 FOR HIGHER VALUES OF E 2 / E1 . .............................................................................................................................................. 89 FIGURE 5.10: DIMENSIONLESS AR VS. DIMENSIONLESS FREQUENCY FOR MODEL 4 FROM FOR LOWER VALUES OF 1 . ................................................................................................................................... 89 FIGURE 5.11: DIMENSIONLESS AR VS. DIMENSIONLESS FREQUENCY FOR MODEL 4 FOR HIGHER VALUES OF 1 . ..................................................................................................................................................... 90 FIGURE 5.12: DIMENSIONLESS AR VS. DIMENSIONLESS FREQUENCY FOR MODEL 5 FOR VARIOUS VALUES OF . .................................................................................................................................................. 90 FIGURE 5.13: DIMENSIONLESS AR VS. DIMENSIONLESS FREQUENCY FOR MODEL 6 FOR VARIOUS VALUES OF 1 /2 RATIO WITH 1 MAINTAINED CONSTANT. ............................................................................ 90 FIGURE 5.14: DIMENSIONLESS AR VS. DIMENSIONLESS FREQUENCY FOR MODEL 6 FOR VARIOUS VALUES OF 1 /2 RATIO WITH 1 MAINTAINED CONSTANT. ............................................................................ 90 FIGURE 5.15: DIMENSIONLESS AR VS. DIMENSIONLESS FREQUENCY FOR MODEL 6 .................................. 90 FIGURE 6.1: COMPARISON OF LITERATURE DATA TAKING IN TO ACCOUNT BLOOM NUMBER AND CONCENTRATION. DATA FROM KOOB ET AL. 2002, HALL ET AL. 1997, BIGI ET AL. 1998, JANIS ET AL. 2002, YANG 2007, TANG ET AL. 2009, MADSEN ET AL. 2003, JULIANO ET AL. 2006 AND USTA ET AL. 2003.................................................................................................................................................. 102 FIGURE 6.2: PLOT SHOWING MEASURED E FROM LITERATURE PLOTTED AGAINST VALUES CALCULATED USING MODEL 5. ............................................................................................................................... 104 FIGURE 6.3: EXTRAPOLATION OF A) E1 , B) E2 AND C) 2 TO ZERO OIL CONCENTRATION, D) ECalculated PLOTTED AGAINST GEL CONCENTRATION FOR PUBLISHED VALUES AND PLOTS, E) PLOT SHOWING MEASURED E FROM LITERATURE PLOTTED AGAINST VALUES CALCULATED USING MODEL 5. DATA FROM HALL ET AL. 1997, BIGI ET AL. 1998, YANG 2007, MADSEN ET AL. 2003, JULIANO ET AL. 2006 AND USTA ET AL. 2003. ..................................................................................................................... 106 FIGURE 6.4: PLOTS FOR SYSTEMATIC TESTING-I, DAY AND FREQUENCY AVERAGED SHOWING STRAIN SENSITIVITY FOR MEASURED A) AR C) PD AND E) MR AT MACRO-SCALE AND B) AR AND D)PD AT MICRO-SCALE. ................................................................................................................................... 107 FIGURE 6.5: PLOT SHOWING MEASURED E FROM LITERATURE PLOTTED AGAINST VALUES CALCULATED USING MODEL 3 FOR A) COLLAGEN BASED TISSUES AND B) FAT TISSUES. DATA FROM PARK AND ATESHIAN, 2006; SIMHA ET AL. 1999; KORHONEN ET AL. 2002; JIN AND LEWIS, 2003; LI ET AL. 2003; KROUSKOP ET AL. 1998; GEFEN AND HABERMAN, 2007; GEERLIGS ET AL. 2008; SAMANI ET AL. 2007; VERTERAMO ET AL. 2004................................................................................................................... 110 FIGURE 6.6: EFFECTS OF INHOMOGENITY AND NON-LINEARITY ON STIFFNESS. ........................................ 113 FIGURE 6.7: VARIATION OF MEASURED STATIC MODULUS (MR) WITH TOTAL DISPLACEMENT FOR GELATINE AND TISSUE SAMPLES. ....................................................................................................................... 113 FIGURE 6.8: DIFFERENCE IN SECANT MODULUS FOR SMALL AND LARGE STRAINS WITH NEGATIVE CURVATURE. ..................................................................................................................................... 113 FIGURE 6.9: DIFFERENCE IN SECANT MODULUS FOR SMALL AND LARGE STRAINS WITH POSITIVE CURVATURE. ..................................................................................................................................... 113 FIGURE 6.10: DISTRIBUTIONS OF MACRO-SCALE AND MICRO-SCALE DYNAMIC MODULUS FOR COLLAGEN TISSUE. HISTOGRAMS A) AND B) SHOW ENTIRE DISTRIBUTION WHEREAS C), D) SHOW THE PEAK GAUSSIAN FITS. ................................................................................................................................. 114 FIGURE 6.11: CHANGE IN STATIC MODULUS (PA) WITH CHANGE IN VOLUME DISPLACED BY THE INDENTER (µM3) FOR NEARLY HOMOGENEOUS GELS AND RUBBER (TISSUE MIMICS)........................................... 122 FIGURE 6.12: Estatic VS. VOLUME PROBED ( m 3 ) FOR BIOLOGICAL TISSUE (LIGAMENTUM NUCHAE). ...... 123 FIGURE 6.13: E VS. VOLUME PROBED ( m 3 ) FOR BIOLOGICAL TISSUE (LIGAMENTUM NUCHAE)......... 123 FIGURE 6.14: MACRO-SCALE, STRUCTURE-PROPERTY RELATIONSHIP, GELATINE IN OIL PHANTOMS, GEL CONCENTRATION VS. A) E1 , B) E2 ,C) 2 AND, OIL CONCENTRATION VS. D) E1 , E) E2 , F) 2 AND THE GEL CONCENTRATION VS. G) E ( 0 , gel ) , H) K( E1 , E2 ), I) 2 ( 0 , gel ) ............................................. 126 FIGURE 6.15: MICRO-SCALE, STRUCTURE-PROPERTY RELATIONSHIP FOR GELATINE IN OIL PHANTOMS. .. 128 FIGURE 6.16: MACRO-SCALE, STRUCTURE-PROPERTY RELATIONSHIP, BIOLOGICAL TISSUES. .................. 129 FIGURE A1.0.1: THE 3-PARAMETER VISCO-ELASTIC MODEL, MODEL 5 WITH ILLUSTRATIONS OF INDIVIDUAL AND TOTAL STRESS, STRAIN COMPONENTS. ................................................................... 150 FIGURE A1.0.2: THE 3-PARAMETER VISCO-ELASTIC MODEL, MODEL 4 WITH ILLUSTRATIONS OF INDIVIDUAL AND TOTAL STRESS, STRAIN COMPONENTS. ................................................................... 151 FIGURE A1.0.3: THE 3-PARAMETER VISCO-ELASTIC MODEL, MODEL 3 WITH ILLUSTRATIONS OF INDIVIDUAL AND TOTAL STRESS, STRAIN COMPONENTS. ................................................................... 153 FIGURE B. 0.4: PRELIMINARY EXPERIMENT I, AMPLITUDE RATIO-TESTS-1-4. ......................................... 155 FIGURE B. 0.5: PRELIMINARY EXPERIMENT I, PHASE DIFFERENCE-TESTS-1-4......................................... 156 FIGURE B. 0.6: PRELIMINARY EXPERIMENT I, MEAN RATIO-TESTS-1-4................................................... 156 FIGURE B. 0.7: PRELIMINARY EXPERIMENT I, AMPLITUDE RATIO, TESTS-5-8. ........................................ 157 FIGURE B. 0.8: PRELIMINARY EXPERIMENT I, AMPLITUDE RATIO-TESTS-9-12. ....................................... 157 FIGURE B.0.9: PRELIMINARY EXPERIMENT I, PHASE DIFFERENCE, TESTS-5-8. ........................................ 157 FIGURE B.0.10: PRELIMINARY EXPERIMENT I, PHASE DIFFERENCE, TESTS-9-12. .................................... 157 FIGUREB.0.11: PRELIMINARY EXPERIMENT I, MEAN RATIO,TESTS-5-8................................................... 157 FIGURE B.0.12: PRELIMINARY EXPERIMENT I, MEAN RATIO, TESTS 9-12................................................. 157 FIGURE B.0.13: PRELIMINARY EXPERIMENT II, AMPLITUDE RATIO, TESTS 4-16. ANOVA SINGLE FACTOR TEST SHOWED AR VARIED SIGNIFICANTLY WITH FREQUENCY ON BOTH DAYS. ................................. 158 FIGURE B.0.14: |PRELIMINARY EXPERIMENT II, PHASE DIFFERENCE, TESTS 4-16. ANOVA SINGLE FACTOR TEST SHOWED PD VARIED SIGNIFICANTLY WITH FREQUENCY ON BOTH DAYS. .................................. 159 FIGURE B.0.15: PRELIMINARY EXPERIMENT II, MEAN RATIO, TESTS 4-16. ANOVA SINGLE FACTOR TEST SHOWED MR DID NOT VARY SIGNIFICANTLY WITH FREQUENCY ON BOTH DAYS. .............................. 159 List of Tables TABLE 2.1: LIST OF COMPARISONS BETWEEN UNI-AXIAL AND MULTI-AXIAL TESTING. ............................... 12 TABLE 2.2: EXAMPLES OF IN-SITU, INDENTATION BASED CLINICAL DIAGNOSTIC DEVICES FROM LITERATURE. ....................................................................................................................................... 19 TABLE 2.3: COMPARISON OF YOUNG’S MODULUS (KPA) OF SOFT, HARD AND CANCEROUS HUMAN BREAST AND PROSTATE TISSUES MEASURED UNDER UNI-AXIAL COMPRESSION, IN VITRO,CA= CARCINOMA (CANCEROUS), BPH= BENIGN PROSTATIC HYPERPLASIA. TABLE FROM KROUSKOP ET AL. (1998)....... 21 TABLE 2.4: COLLECTION OF REPORTED MECHANICAL PROPERTIES OF COLLAGEN BASED TISSUES ALONG WITH THEIR RESPECTIVE TEST CONDITIONS. ........................................................................................ 23 TABLE 2.5: MECHANICAL PROPERTIES OF PURE GELATINE OR GELATINE COMPOSITES MEASURED USING DYNAMIC AND STATIC TESTING COLLECTED FROM LITERATURE. ........................................................ 26 TABLE 3.1: LIST OF OIL IN GELATINE FORMULATIONS. ............................................................................... 33 TABLE 3.2: FINAL RESULTS OF DATA PROCESSING OF FILE “13-MEAN2-10STEPS-01HZ.TXT”. .................... 43 TABLE 3.3: EXPERIMENT I, TEST CONDITIONS. ............................................................................................ 46 TABLE 3.4: EXPERIMENT-II, TEST CONDITIONS. ......................................................................................... 47 TABLE 3.5: SYSTEMATIC TESTING, TEST CONDITIONS PER DAY OF TESTING ............................................... 48 TABLE 3.6: RESULTS OF Z-MOTOR SPEED CALIBRATION EXPERIMENT ........................................................ 54 TABLE 3.7: CALCULATION OF AMPLITUDE RATIO AND PHASE DIFFERENCE FOR THE RECORD FOR GELATINE FORMULATION-9, 1 DAY OLD, TESTED AT 10HZ WITH INPUT DISPLACEMENT AMPLITUDE OF AROUND 30NM. ................................................................................................................................................. 58 TABLE 3.8: MEAN AND STANDARD DEVIATION (SD) OF THE RESULTS OF REPEATABILITY EXPERIMENT. ... 59 TABLE 3.9: SUMMARY OF ALL THE EXPERIMENTS PERFORMED IN THIS STUDY. .......................................... 61 TABLE 4.1:DATA CODING SYSTEM USED IN FIGURES OF SYSTEMATIC TESTING. ......................................... 62 TABLE 5.1: SUMMARY OF RESULTS FROM TWO FACTOR (FREQUENCY, Max ) ANOVA FOR SYSTEMATIC TESTING OF GELATINE PHANTOMS AT MACRO-SCALE. ......................................................................... 80 TABLE 5.2: SUMMARY OF RESULTS FROM ANOVA TWO FACTOR ANALYSIS (GELATINE PHANTOM TYPE, Max ), FOR SYSTEMATIC TESTING OF GELATINE PHANTOMS AT ANALYSIS. ........................................ 80 TABLE 5.3: SUMMARY OF RESULTS FROM ANOVA TWO FACTOR ANALYSIS (FREQUENCY, Max ) FOR SYSTEMATIC TESTING OF BIOLOGICAL TISSUES AT MACRO-SCALE. ..................................................... 81 TABLE 5.4: SUMMARY OF RESULT FROM ANOVA TWO FACTOR ANALYSIS (MATERIAL CLASS, Max ) FOR SYSTEMATIC TESTING OF BIOLOGICAL TISSUES AT MACRO-SCALE ...................................................... 82 TABLE 5.5: RESULT FROM ANOVA TWO FACTOR TEST -1 (FREQUENCY, Max ) FOR MICRO-SCALE, SYSTEMATIC TESTING, GELATINE PHANTOMS. ..................................................................................... 82 TABLE 5.6: RESULT FROM ANOVA TWO FACTOR TEST (MATERIAL TYPE, Max ) FOR MICRO-SCALE, SYSTEMATIC TESTING, GELATINE PHANTOMS. ..................................................................................... 83 TABLE 5.7: SUMMARY OF EQUATIONS INVESTIGATED FOR CONSTITUTIVE PARAMETER MODELLING. ........ 85 TABLE 5.8: DIMENSIONLESS AMPLITUDE RATIO AND PHASE EQUATIONS FOR ALL 3-PARAMETER MODELS. 88 TABLE 5.9: CURVE FITTING RESULTS, GELATINE FORMULATIONS, TESTED AT MACRO-SCALE FOR MODEL 3. ............................................................................................................................................................ 92 TABLE 5.10: CURVE FITTING RESULTS, GELATINE FORMULATIONS, TESTED AT MACRO-SCALE FOR MODEL 4.......................................................................................................................................................... 92 TABLE 5.11: CURVE FITTING RESULTS, GELATINE FORMULATIONS, TESTED AT MACRO-SCALE FOR MODEL 5.......................................................................................................................................................... 92 TABLE 5.12: CURVE FITTING RESULTS, GELATINE FORMULATIONS, TESTED AT MACRO-SCALE FOR MODEL 6.......................................................................................................................................................... 93 TABLE 5.13: MATERIAL PROPERTIES FROM CURVE FITTING MEASURED RESULTS OF PURE GELATINE, MACRO-SCALE FOR MODEL 5. ............................................................................................................. 93 TABLE 5.14: MATERIAL PROPERTIES CALCULATED USING WEIGHTED AVERAGE ( P( AR, PD) ) FROM CURVE FITTING MEASURED RESULTS OF GELATINE SAMPLES FOR MODEL 5 AT MACRO-SCALE. ...................... 94 TABLE 5.15: MATERIAL PROPERTIES OBTAINED FROM CURVE FITTING EXPERIMENTAL RESULTS OF BIOLOGICAL SAMPLES FOR MODEL 3 AT MACRO-SCALE. ..................................................................... 94 2 TABLE 5.16: MATERIAL PROPERTIES CALCULATED USING WEIGHTED AVERAGE ( P( AR, PD) ) FROM CURVE FITTING EXPERIMENTAL RESULTS OF BIOLOGICAL SAMPLES FOR MODEL 3 AT MACRO-SCALE. ........... 94 TABLE 5.17: MATERIAL PROPERTIES OBTAINED FROM CURVE FITTING EXPERIMENTAL RESULTS............... 95 2 TABLE 5.18: MATERIAL PROPERTIES CALCULATED USING WEIGHTED AVERAGE ( P( AR, PD) ) FROM CURVE FITTING EXPERIMENTAL RESULTS OF MICRO-SCALE, GELATINE SAMPLES FOR MODEL 5. .................... 95 TABLE 6.1: MEASURED PRIMARY STATIC AND DYNAMIC MECHANICAL PROPERTIES FROM RAW DATA FOR BOTH SCALES, GELATINE PHANTOMS, AVERAGED OVER THE AGES, FREQUENCIES AND STRAIN USED. 99 TABLE 6.2: GEL CONSTITUENTS AND YOUNG’S MODULUS OF GELATINE AND/OR ITS COMPOSITES. DATA FROM KOOB ET AL. 2002, HALL ET AL. 1997, BIGI ET AL. 1998, JANIS ET AL. 2002, YANG 2007, TANG ET AL. 2009, MADSEN ET AL. 2003, JULIANO ET AL. 2006 AND USTA ET AL. 2003. .................................. 100 TABLE 6.3: MATERIAL PROPERTIES FROM CURRENT WORK OBTAINED USING MODEL 5. .......................... 102 TABLE 6.4: QUASI-STATIC EXTRAPOLATION OF YOUNG’S MODULUS FOR OIL IN GELATINE PHANTOMS USING EXPERIMENTAL CONDITIONS FROM THE LITERATURE. ............................................................ 103 TABLE 6.5: AVERAGED STATIC, DYNAMIC MECHANICAL PROPERTIES FROM RAW DATA FOR MACRO-SCALE, BIOLOGICAL TISSUES, (DAY, STRAIN AND FREQUENCY AVERAGED) AND VALUES OF ELASTIC AND VISCOUS PARAMETERS OBTAINED FROM MODEL-3 FITTING. RANGE IN THE MEASUREMENT IS DUE TO FREQUENCY IN THE RANGE 1 – 10HZ. ............................................................................................... 108 TABLE 6.6: STATISTICS FOR STATIC AND DYNAMIC MODULUS FOR GELATINE AND BIOLOGICAL SPECIMENS ACROSS MACRO AND MICRO-SCALES. ................................................................................................ 112 TABLE 6.7: INTERNAL AND EXTERNAL COMPARISON OF MATERIAL TYPE, INDENTER GEOMETRY , STRAIN PROFILE, E, E AND VOLUME DISPLACED BY INDENTERS FOR NEARLY HOMOGENEOUS MATERIALS (GELS, RUBBER)................................................................................................................................. 121 TABLE 6.8: INTERNAL AND EXTERNAL COMPARISON OF TISSUE TYPE, INDENTER GEOMETRY PROFILE, STRAIN PROFILE, STATIC AND DYNAMIC MODULUS AND VOLUME DISPLACED BY INDENTERS FOR COLLAGEN BASED TISSUES. ............................................................................................................... 121 TABLE 6.9: COEFFICIENTS OF LINEAR AND POWER LAW FITS AND THEIR CORRELATION COEFFICIENTS FOR FIGURES 6.14. .................................................................................................................................. 126 List of Publications Published: 1) Lakshmanan V., Yang T.H.J., Reuben R.L., Hammer J., Else R.W.,. "Assessing the quality of biological tissues using structure-property relationships: macro-scale tests on engineered phantoms." Studies in Health Technology and Informatics. 133(1), (2008): 166-82. 2) Lakshmanan V., Yang T.H.J., Reuben R.L., Hammer J., Else R.W.,"Multiscale techniques of measuring the dynamic properties of biological tissues." Technology and Health Care. 14(4-5), (2006): 297-309. Planned: 3) “Structure – property relationships in gelatine-oil mixtures-a model system for biological materials” to be submitted to Proceedings of IMechE, Journal of Engineering in Medicine. 4) “The effects of collagen and lipid content on the visco-elastic behaviour of ovine connective tissue” to be submitted to Journal of the Mechanical Behaviour of Biomedical Materials. 5) “Scale effects on the viscoelastic properties of soft biological materials” to be submitted to Journal of the Mechanical Behaviour of Biomedical Materials.