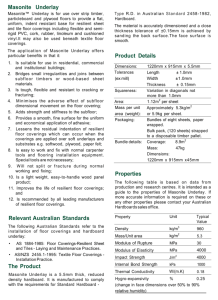

Durafloor M Spec Clause

advertisement

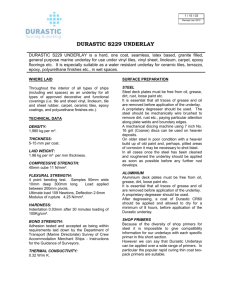

Product Specification Durafloor M Flexible floor underlay, epoxy urethane levelling mortar for carpet / tiles for marine vessels (1mm – 10mm thickness) *1.00 Marine Floor Underlay Treatment 1.10 Substrate Preparation (steel or aluminium) 1.11 General All surfaces shall be prepared, primed and the underlay material applied strictly in accordance with the current manufacturer technical data sheet. All work shall be carried out by an experienced contractor, who is well trained in the application of the specific, documented, underlay system. All materials used in conjunction with the underlay system, shall be approved by the underlay manufacturer. 1.12 Surface Preparation Thorough surface preparation is vital. Mechanically abrade the metal substrate with grinding or blasting. The host metal substrate must be sound, clean, and dry to achieve the maximum adhesion. The surface must be fine textured. Any excessive surface irregularities or deep profiles must be treated prior to application. 1.13 Priming Once the surface has been fully prepared, it is to be primed using Durafloor M Primer, and let dry. 1.20 Standards Compliance Durafloor M has been tested by the “Warrington Fire Research Group” to the International Maritime Organisation (I.M.O.) Fire Test Procedures for Surface Flammability of Bulkhead, Ceiling and Deck Finish Materials and conforms with Resolution A653 (16) as amended by Resolution MSC 61 (67). Parchem Construction Supplies Document Date: 09/2009 Page 1 of 2 Parchem offers direct assistance with specifications for individual projects; we can visit the site, design office, or arrange a meeting at our branch office. It is recommended that Parchem be consulted early in the design process. For Technical Data Sheets (TDS), Specifications and Method Statements, please visit our website at www.parchem.com.au. * To insert the Specification, Copy and Paste. Product Specification 1.30 Marine Floor Underlay Material 1.31 Those areas nominated on the drawings, are to receive a flexible, epoxy-urethane levelling mortar for carpet or tiles, formulated for marine vessels. The mortar is to consist of a special blend of selected polyurethane resins, curing agents, and inert lightweight fillers, which when mixed can be applied to provide a 1mm – 10mm smooth underlay topping with unique application and performance properties. Material properties Pot life: Initial cure (light foot traffic) Final cure Physical properties – Service temperature range: Elongation: Tensile bond to steel or alloy: 24 hours @23oC 3 days @ 23oC minus 10oC to 55oC 5% 2 MPa 1.32 Durafloor M manufactured by Parchem Construction Supplies meets the product criteria and is approved. Parchem Construction Supplies Document Date: 09/2009 Page 2 of 2 Parchem offers direct assistance with specifications for individual projects; we can visit the site, design office, or arrange a meeting at our branch office. It is recommended that Parchem be consulted early in the design process. For Technical Data Sheets (TDS), Specifications and Method Statements, please visit our website at www.parchem.com.au. * To insert the Specification, Copy and Paste.