Masonite Underlay - STM Studio Supplies

advertisement

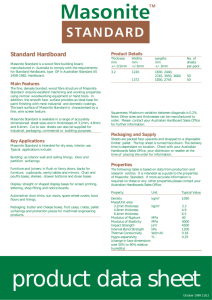

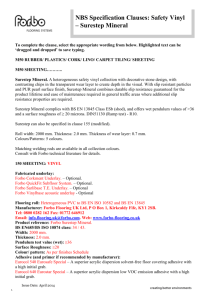

Masonite Underlay Masonite™ Underlay is for use over strip timber, particleboard and plywood floors to provide a flat, uniform, indent resistant base for resilient sheet and tile floor coverings including flexible and semirigid PVC, cork, rubber, linoleum and cushioned vinyl.lt may also be used beneath textile floor coverings. The application of Masonite Underlay offers particular benefits in that it: 1. Is suitable for use in residential, commercial and institutional buildings; 2. Bridges small irregularities and joins between s u b f l o o r t i m b e r s or wood-based sheet materials. 3. Is tough, flexible and resistant to cracking or fracturing; 4. Minimises the adverse effect of subfloor dimensional movement on the floor covering; 5. Adds strength and stiffness to the subfloor; 6. Provides a smooth, fine surface for the uniform and economical application of adhesive; 7. Lessens the residual indentation of resilient floor coverings which can occur when the coverings are applied over soft underlays and substrates e.g. softwood, plywood, paper felt; 8. Is easy to work and fix with normal carpenter tools and flooring installation equipment. Special tools are not necessary; 9. Will not split or f r a c t u r e during normal working and fixing; 10. Is a light weight, easy-to-handle wood panel product; 11. Improves the life of resilient floor coverings; and 12. Is recommended by all leading manufacturers of resilient floor coverings. Relevant Australian Standards The following Australian Standards refer to the installation of floor coverings and hardboard underlay: • • AS 1884-1985: Floor Coverings-Resilient Sheet and Tiles - Laying and Maintenance Practices. AS/NZS 2455.1-1995: Textile Floor Coverings Installation Practice. The Product Masonite Underlay is a 5.5mm thick, reduced density hardboard. It is manufactured to comply with the requirements for Standard Hardboard - Type R.D. in Australian Standard 2458-1982, Hardboard. The material is accurately dimensioned and a close thickness tolerance of ±0.15mm is achieved by sanding the back surface.The face surface is smooth. Product Details Dimensions: Tolerances (ex mill) Squareness: Area: Mass per unit area (weight): Packaging: Bundle details: 1220mm x 915mm x 5.5mm Length ± 1.0mm Width ±1.0mm Thickness ± 0.15mm Variation in diagonals not more than 1.0mm 1.12m2 per sheet Approximately 5.3kg/m2 or 5.9kg per sheet. Bundles of eight sheets, paper wrapped. Bulk pack, (120 sheets) strapped to a disposable timber pallet. Coverage: 8.9m2 Mass: 47kg Dimensions: 1220mm x 915mm x45mm Properties The following table is based on data from production and research centres. It is intended as a guide to the properties of Masonite Underlay. If more accurate information is required on these or any other properties please contact your Australian Hardboards sales office. Property Unit Typical Value Density kq/m3 2 960 Mass/Unit area kg/m 5.3 Modulus of Rupture MPa 30 Modulus of Elasticity MPa 4000 Impact Strength J/m2 4000 Internal Bond Strength kPa 1000 Thermal Conductivity W/(m.K) 0.18 Hygro-expansivity % 0.25 (change in face dimensions over 50% to 90% relative humidity) Handling and Storage Sheet Layout Keep clear of sharp protrusions. Stack panels flat on pallets or timber runners in a dry area with a moderate temperature and reasonably constant relative humidity. Remove the Masonite Underlay sheets from the bundle and lay them, smooth face upwards on the floor surface. (See also "Site Conditions.") Storage in direct sunlight, damp locations or hot, dry buildings should be avoided. Subfloor Suitable subfloors for the application of Masonite Underlay include: 1. New or old structural timber floors. 2. Structural Plywood Flooring. 3. Structural Particleboard Flooring. Installation Preparation Before installing Masonite Underlay, check that the ventilation to the subfloor area is adequate and provides a clear cross flow of air beneath the floor. The subfloor area should be free of excess moisture vapour and dampness. (Refer "Site Conditions.") The subfloor timbers and flooring must be in reasonable condition, dry and free from decay. Arrange the sheets in the rows in an ashlar or brickwork pattern. Keep the long edges at right angles to the run of the flooring. Allow a 3mm gap between the sheet edges and room perimeter. Also where the sheets meet other fixtures. Bring adjoining sheets almost into contact with one another. Do not force them together. The preferred gap between sheets is 0.4mm. The sheet joins should be located over the centre of floorboards. Cutting Masonite Underlay can be cut and worked with normal carpenter tools. Cut sheets with a fine tooth hand or power saw. P r o f e s s i o n a l floor layers may prefer to cut Masonite Underlay with a linoleum or Stanley knife. Always keep the cut edges to the room perimeter. Replace any loose or broken boards. Floor nails should be punched below the floorboard surface. Masonite Underlay is sufficiently rigid to bridge minor irregularities in the floor surface. The best results are obtained when the floor is machine sanded to a flat plane. A convenient way to mark and cut Masonite Underlay to fit up to walls is to slide the sheet under the unfixed edges of the previous sheet as shown. Fixing Staples or nails are recommended to fix Masonite Underlay to strip timber subfloors. Location of joins over typical strip timber and sheet flooring. On structural particleboard and plywood sheet flooring it is advisable to use staples or nails in conjunction with adhesive. Staples Use 22mm minimum length galvanised or copper etched narrow crown type, preferably resin coated. The recommended nails will give better hold than staples and are preferred for softwood floors, such as Pinus Radiata and Baltic Pine. Fastener Spacings The correct spacings for staples and nails into strip timber floors are 75mm at the sheet edges, 10mm from the edge and 150mm throughout the body of the board. Ensure that the fasteners are not driven into the floorboard joins. Adhesives Use adhesive with staples or nails when fixing Masonite Underlay to structural sheet flooring. Adjust the staple gun to set the staple crown 0.4mm maximum below the Masonite Underlay surface. Suitable adhesives include neoprene type wallboard or construction grade adhesives such as H.B. Fullers "Maxbond". Staples must not be driven deeply into the board. Some high solids, flexible PVA adhesives may also be used. Please obtain advice from the adhesive manufacturer. Nails Apply the adhesive to structural sheet flooring in a grid pattern approximately 150mm apart in both directions. Wallboard type adhesives are usually applied by sealant gun in continuous beads a p p r o x i m a t e l y 5mm diameter. Use 25mm x 2mm x 3.5mm head, ring grooved buttress type underlay nails. PVA type adhesive may be applied with a fine "V" notched spreader, 1.5mm x 1.5mm maximum. Only apply sufficient adhesive to fix one sheet at a time. Drive nails flush with or slightly below the Masonite Underlay surface. Laying procedure and fastenings PART PLAN Position the Masonite Underlay and fasten with nails or staples spaced at 150mm centres at sheet edges and throughout the board. Adhesives should be applied in accordance with the manufacturers instructions. Do not use adhesive when fixing Masonite Underlay to strip timber floors. Fastener Spacings Finishing Check to ensure that all fasteners are correctly driven and that fasteners heads are not proud of the board surface. Carefully sand the Masonite Underlay joins to a flat plane. Also sand the fixing points to remove any fibre build-up. When sanding, use a flat based machine sander or sandpaper block. Do not use small disc type sanders. Sweep or vacuum the floor so that all dust and loose fibre is removed. The Masonite Underlay is then ready to receive the floor covering material. Floor Coverings The floor covering manufacturer's instructions should be followed in relation to the selection and use of adhesive and for the installation of the floor covering material. Where required, the Masonite Underlay surface may be sealed to suite some adhesive systems. Use shellac/methylated spirits solution or proprietary sealers in accordance with the adhesive manufacturer's instructions. Semi-rigid vinyl tiles should be bonded with an adhesive which remains permanently tacky, such as "Staybond 7102" Vinyl Flooring Adhesive, manufactured by International Adhesives and Resins Pty Ltd. The cause of moisture must be corrected and the floor allowed to dry. Subfloor ventilators should provide a clear, cross flow of air beneath the floor so that any excessive moisture vapour is removed from the subfloor area. Excess moisture and dampness can lead to the distortion and possible decay of flooring members and excessive movement of the Masonite Underlay. Adequate ventilation is particularly important where impervious floor coverings are used, as they restrict the escape of moisture through the floor. In some circumstances, a moisture impervious membrane, such as polyethylene film or bitumen impregnated felt, may be used to cover the ground beneath the floor to retard moisture rise. Further information on subfloor ventilation is contained in the Forestry Commission of NSW Technical Publication No. 11 - "Ventilation Under Timber Floors." Copies are available from your Australian Hardboards sales office. Under normal climatic conditions, Masonite Underlay may be used direct from the bundle, however, best results will be achieved when the Masonite Underlay is loose laid on the floor for 24 hours before fixing. This will allow the material to equilibrate its moisture content with the site conditions. The practice of loose laying the board for 24 hours is strongly recommended where there is any doubt on the adequacy of the subfloor ventilation. Site Conditions Note Prevailing climatic or installed environmental conditions can influence moisture content changes in wooden floors and underlays. The resulting dimensional movement may become noticeable where the floor covering bridges the Masonite Underlay joins. In some cases, the joins may be highlighted by the effects of glancing light on the floor surface. Masonite Underlay should only be installed over floors which are adequately ventilated and where there are no indications of dampness.