Curvy Stuf 101 - DiMonte Group Inc.

advertisement

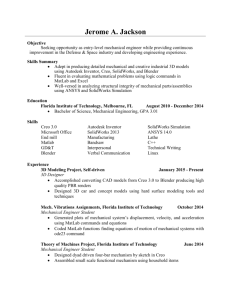

Curvy Stuf 101 Inspiration: Like everyone else in the late 90’ss/early 00’s, I was struggling to try to figure out how the core SWx curvy features really worked, informed only by spotty, sometimes conflicting, and occasionally (and disturbingly) false resources from training, SolidWorks corp, Vars, and user groups. This has not been eliminated over time, by the way – in spring of 2007 I went to a VAR presentation that gave wrong advice over and over again about modeling curvy stuff (note: this info was objectively wrong, I have enough character to sit back when someone presents a different approach than I would take they presented things that simply did not work, even when the Var demo-jocks tried it on screen, yet they pretended that it DID WORK?!?! or excused it as a quirk. It was surreal. My policy is if it doesn’t work, it doesn’t work… so let’s find out how to make it work and share that knowledge). At the time I dove in to reverse engineer SolidWorks and test everything that I could in the curvy features so I could model the shapes that I needed to for my job. After working a lot of it out, it seemed like a shame that every other user interested in the same sort of modeling would have to go through the same laborious testing process, so I took additional time to document and present my findings. Good thing, too – I personally gave this presentation to developers at SolidWorks in Concord and subsequently some of the more painful bits have been removed from the software. Please note that many items in this presentation are out of date by subsequent improvements in SWx. As with any presentation you see or find online, be it mine, someone elses, or even God’s, don’t take anything on faith – test everything out for yourself ! Abstract: This presentation goes beyond the tutorials and takes a detailed, deconsructive look at the construction and capabilities of SolidWorks organic modeling features in SWx 2001+ 9some of which have been improved on or superceded by later versions). Benefit: In this session, attendees learn how to overcome the feature-level issues that frequently prevent users from developing the organic shapes they require. Curvy Stuff 102 Inspiration Having been to SWx world a couple of times, and been for years an eager consumer of any SWx tips I could get my hands on, I noticed that there was a huge hole in the available worldwide conversation about modeling curvy features in SolidWorks. Sure, Individual features have their issues (see Curvy Stuff 101) and there was plenty of traffic on that topic, but the much harder problem was bringing Curvy Features and other features together into a single model. So this, my first and probably most important contribution to the conversation about SolidWorks, discusses how SolidWorks works behind the scenes and the ways you can use that knowledge to overcome modeling issues Abstract: In this session, attendees gain the confidence to conquer the challenges of bringing complex features together. Topics for discussion include: surfaces versus solids, overcoming awful modeling challenges, filleting problems, and more. Benefit: Attendees learn how to overcome modeling roadblocks by understanding how SolidWorks works at a root level. The importance of knowing the interchangeability of surfaces and solid features, the critical fact of the BREP behind it all, and that every feature is just a macro for creating faces is critical to anyone who wants to push SolidWorks modeling beyond simple blocky shapes Curvy Stuff V – The Wrath of Scotty, Part 1 Inspiration: Abstract: How can Engineers work with the curvy models delivered by Industrial Designers? Part 1 focuses on the differences in the disciplines of industrial Design and Engineering and why their models so often seem incompatible, It provides and understanding od what causes the other camp to model “that way” and presents modeling strategies, tips and tricks to ease collaboration on curvy products Pulling critical to function dimensions from the industrial designers model into the drawing Benefit: Both Engineers and Industrial Designers will learn how to better collaborate with each other and share a common SolidWorks database that caters to the professional requirements of both disciplines. Curvy Stuff V – The wrath of Scotty, Part 2 Benefit: Both Engineers and Industrial Designers will learn proven real-world techniques to get past tough modeling problems and create manufacturing databases that do not compromise the Industrial Design of their swoopy shapes Abstract: Part 2 discusses tips and trick for the engineer and Industrial Designer to turn the Industrial Designers SWx models into a manufacturable database. Using Cast, injection molded, forged, and vacuum-formed samples, the session covers how to handle modeling overmolds, tough draft problems, “shelling” models that won’t shell, modeling complex shutoffs, creating ribs from non-planar parting lines, and managing ‘mastermolde’ files. Trees of blood Inspiration: The single issue that, in my observations of my coworkers and clients, caused the greatest loss in productivity was rebuild errors. Users would make a change in their model or assembly that caused rebuild errors and they would become apoplectic – instead of calmly going about the business of fixing their models, they would spend inordinate amounts of time complaining about how their parts ‘blew up’, freeze and not do anything, respond in a way that exasperated the problem, or (worst case) ditch changes necessary to the improvement of their designs because those changes caused errors. Early on I embraced rebuild errors as the price of doing SolidWorks design, developed techniques to get through them quickly and painlessly, and over time embraced them as a useful check for identifying issues where design intent might be compromised by design changes. I never wanted to do a presentation about handling rebuild errors because each one of these presentations takes well over 100 hours to compose, format, and test, test, test. Unfortunately for me, no one else stepped up (regardless of the lobbying and attempted recruiting on my part). Even the training material is pretty lean about the topic, though it is in my experience the biggest, most common productivity issue run into by SolidWorks users. So I did it. If nothing else, the clear, proven techniques for how to delete a feature without losing any of child features is worth the time to look at it. And I hope anyone who reads this will learn that rebuild errors are not a big deal and can stop spending their time criping about how their model ‘blew up’ or ‘errored out’ and instead spend that criping time calmly fixing it. Its really easy and won’t raise your blood pressure a tic if you know what you are doing. Benefit: attendes will leave this sessiona rmed with the best pactices that will minimize their exposre to rebuild errors, and some great tips and techniques that will allow them to quickly and painlessly repair their SolidWorks files and get back in action. Most importantly, the will learn to calm down when their feature trees erupt in bolld – they will learn that most can be fixed in seconds (when one knows how) so they can fix their models and get back to designing Abstract: We have all been there : we make a necessary change to a design, and the feature tree “blows-up” with rebuild errors. This session covers how to quickly and painlessly repair rebuild errors in part models by understanding why they happen and discuusses tips, tricks, and techniques to repair them fast without ever hacing to delet and recreat anything. The discussion also highlights proven modeling habits that prevent rebuild errors in the first place Drawings Inspiration: The Engineer knows the functional requirements and tolerance information at the time they design their product’s components, and are more intimately involved with these ‘critical to function’ dimensions than anyone else on the planet. At the time of the writing of this presentation, it was still common practice to hand components to drafters to add ‘driven’ dimensions to the SolidWorks part drawings, and the drafter had to guess at this important information (worst case) or interrogate the component’s Engineer (slightly less worse case) to create an appropriate drawing. All of the information required for the drawing was ideally captured within the features of the part at the time it was originally authored. Using ‘insert model items’ along with strong design practices during the part modeling stage, the DiMonte Group is able to insure that any Engineer in the organization (even those unfamiliar with the component and its function) can appropriately create a functional detail drawing of components designed by anyone else because the functional dimensions are captured at the part level. Hence the title: ‘Create a drawing without even trying’; if the part is designed correctly, the drawing, from a dimensional and tolerance standpoint, is largely done if the drafter is educated on how to pull that information out of the SolidWorks part. At Swx World 2006 we attended a presentation that showed that 50% of the attendees used ‘insert model items’ to create their drawings. It is good to know that the word is getting out, but we still need to continue posting this presentation until that number becomes 100%.