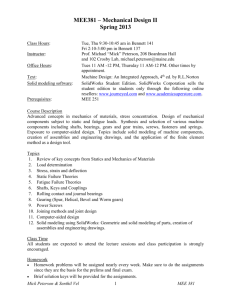

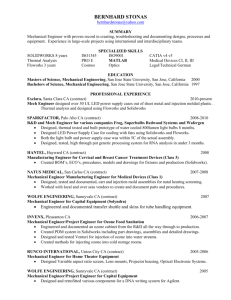

Jerome A. Jackson

advertisement

Jerome A. Jackson Objective Seeking opportunity as entry-level mechanical engineer while providing continuous improvement in the Defense & Space industry and developing engineering experience. Skills Summary Adept in producing detailed mechanical and creative industrial 3D models using Autodesk Inventor, Creo, SolidWorks, and Blender Fluent in evaluating mathematical problems using logic commands in MatLab and Excel Well-versed in analyzing structural integrity of mechanical parts/assemblies using ANSYS and SolidWorks Simulation Education Florida Institute of Technology, Melbourne, FL August 2010 - December 2014 Bachelor of Science, Mechanical Engineering, GPA 3.01 Skills Creo 3.0 Microsoft Office End mill Matlab GD&T Blender Autodesk Inventor SolidWorks 2013 Manufacturing Bandsaw Interpersonal Verbal Communication SolidWorks Simulation ANSYS 14.0 Lathe C++ Technical Writing Linux Experience 3D Modeling Project, Self-driven January 2015 - Present 3D Designer Accomplished converting CAD models from Creo 3.0 to Blender producing high quality PBR renders Designed 3D car and concept models using hard surface modeling tools and techniques Mech. Vibrations Assignments, Florida Institute of Technology October 2014 Mechanical Engineer Student Generated plots of mechanical system’s displacement, velocity, and acceleration using MatLab commands and equations Coded MatLab functions finding equations of motion of mechanical systems with ode23 command Theory of Machines Project, Florida Institute of Technology June 2014 Mechanical Engineer Student Designed dyad driven four-bar mechanism by sketch in Creo Assembled small scale functional mechanism using household items Jerome A. Jackson Florida Institute of Technology Senior Design II January 2014 – May 2014 Mechanical Design Engineer & Team Leader Achieved designing drive system producing 27% belt speed increase Assisted in fabricating robot chassis using carbon fiber and ACRALock adhesive enclosing electronic components from dust and debris Fabricated conveyor structure with pre-preg carbon fiber utilizing aluminum molds and industrial oven Machined parts for belt tensioner and drive system with end mill, lathe, and precision tools following 2D drawings generated in SolidWorks Florida Institute of Technology Senior Design I August 2013 – December 2013 Mechanical Design Engineer Produced concept design of conveyor bed through 3D modeling and analysis in Autodesk and SolidWorks resulting in lightweight and sturdy structure Collaborated concept ideas in multidisciplinary group of engineers (ECE, CSE, and ME) during team meetings Analyzed theoretical performance of conveyor system using relative mechanical engineering equations and Excel spreadsheets Analyzed conveyor’s structural integrity through SolidWorks Simulation Utilized Google Drive to organize and share documents, technical data, and CAD models with team members Volunteer Experience Technology Ministries, Palm Bay, FL August 2004-Present Video & Graphics Operator Controlled video camera and mixer during divine hour service Operated EasyWorship on computer to queue all service elements Collaborated scenario dependent camera maneuvers with team members Trained and assisted newcomers to video and graphical operations Provided customer service for DVD and CD request Awards Senior Design Project President's Cup Award for College of Engineering On-Site Mining Award: 2nd Place Caterpillar’s Autonomy Award: 3rd Place April 2014 May 2014 May 2014