Welding assignment

advertisement

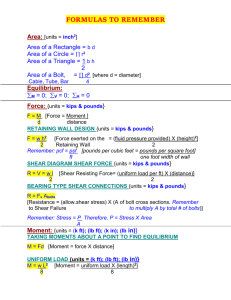

[TYPE THE COMPANY NAME] Welding assignment UNSW MECH3110 Raniya Parappil z3331030 02-Oct-12 Introduction Sugar refining mill is installing vibrating screen units for grading of the sugar into commercial sizes. The unit is supported by brackets that are welded to columns. The screen units are provided with vibration isolation mountings and with internal counterbalancing so that the load may be considered static and uniformly distributed between the four mounting. A reversing horizontal force equivalent to 0.15g peak acceleration occurs in the longitudinal direction at the support brackets [see figure on the left]. The loads exerted on the column are calculated. The screen free body diagram and the bracket A and B free body diagram are drawn. A free body diagram for each bracket in the x-y & x-z planes will be constructed to determine the maximum bending moment and other crucial loadings. The loadings exerted onto the weld outline sections were calculated, using iterations. Material for the beam must be chosen from a catalogue [Figure left shows Side view of the screen unit layout.] Design calculations, sketches of brackets and layouts as required are to be presented for approval by the client's engineer. The bracket A is mounted with an angle therefore it has torsion and bracket is perpendicular to the screen, resulting in no torsion formed. Bracket B is perpendicular to the column which will be cantilever beam with a bending moment due to the screen’s loading. The brackets are the primary focus for this analysis as the welding calculations are performed after the static analysis from the screen to the bracket. SPECIFICATIONS Number of screen units to be installed - 4 Mass of screen unit and fittings - 7000 kg. Location of Centre of Gravity - centrally between mounting feet and at same height as mounting surface Size of Columns - 310 UC 118 [Figure above: Possible bracket detail.] Welding: [Shingley’s textbook, Mechanical Engineering Design] The points that were analyzed on the beam were (the following points were considered to be the critical points Discussion The factor of safety of the beam was considered to be 2. The loads on the screen supports were calculated and the shear force and bending moment diagram were then drawn. After finding this the maximum bending moment for bracket A and B in the planes were found. Free body diagrams were designed for both x-y & x-z. The material of the beam was selected keeping in mind the ASI standards and the section n the x and y plane were found from the One steel catalogue. A general outline on how the shear stress and bending stress will act on the bracket A and B were drawn. A suitable universal beam was selected from the ONE STEEL catalogue. The 530 UB 82 was chosen for being the beam with the smallest flange width that could accommodate the flat plates. The beam had the lightest weight, when compared to the other beams that fit into the design constriction. The bean had to chosen such that, the flange width was between 200 to 307mm. The forces and moment at the weld were calculated with addition to the moment of inertia, Ju, shear force per mm, bending force /mm and torsion/ mm and the angle between the torsion forces were successfully calculated. For the purposes of safe design, a worst case scenario was taken. After choosing the type of load (parallel or transverse), the h (weld size was calculated using the formula:ℎ= ℎ= 3√2𝑓𝑝 𝑛 𝑆𝑢 3 × 1.21𝑓𝑡 𝑛 𝑆𝑢 Then the iteration was used to find the weld size for bracket A and B until the results converged. iteration number 1 2 3 4 5 6 7 8 9 10 average weld 1 1.85 1.63 1.66 1.662 1.66 1.656 1.656 1.656 1.656 weld size A 2.578 1.87 1.91 1.932 1.9073 1.9171 1.9171 1.9171 1.9171 1.9171 weld size B 1.603 1.3865 1.4094 1.4075 1.4092 1.4123 1.4123 1.4123 1.4123 1.4123 Ultimate strenght MPA 250 300 350 400 450 500 weld size for A 4.970677828 4.142231523 3.550484163 3.106673642 2.761487682 2.485338914 weld size for B 3.0910176 2.575848 2.207869714 1.931886 1.717232 1.5455088 factor fo safety 1 2 3 4 5 6 7 8 9 10 11 12 weld size A 1.2890762 2.5781524 3.8672286 5.156304801 6.445381001 7.734457201 9.023533401 10.3126096 11.6016858 12.890762 14.1798382 15.4689144 weld size B 0.801612448 1.603224896 2.404837344 3.206449793 4.008062241 4.809674689 5.611287137 6.412899585 7.214512033 8.016124481 8.817736929 9.619349378 Conclusion: The welding size of the beams was calculated successfully. The screen FBD diagram was drawn to obtain the shear diagram and bending moment diagram. The calculations are done showing the FBDs in the required planes. A free body diagram for each bracket in the x-y & x-z planes has been constructed. The maximum moment for each bracket was calculated in order to get other values which was required for finding the weld size. The factor of safety is assumed in the beginning to calculate the bending moment and shear forces. The critical points of the beam labeled as A B C D E F are taken and analyzed. For each point the shear force, bending force, torsion, and angle were found. A suitable material is then found taken to be structural steel. The weld sizes for both brackets are found using iteration method in excel. Although the weld size may seem small, costs will be lower and the weld size can be modified if necessary by the client’s needs, by changing factor like factor of safety, ultimate tensile strength. the engineering drawing was hence drawn for give the client a basic view of the weld and to put the design into a visual form.