Probabilistic Margins Management of Aerospace Requirements

advertisement

June 2010

Probabilistic Margin Management

Prepared by:

ARES Corporation

1331 Gemini Street, Suite 120

Houston, TX 77058

Table of Contents

Executive Summary ................................................................................................... 3

Problem Statement ..................................................................................................... 3

ARES Solution ........................................................................................................... 4

Merits of ARES Solution ........................................................................................... 4

Technical Description ................................................................................................ 4

Detailed PMM Steps .................................................................................................. 5

PMM Implementation ................................................................................................ 8

Conclusion ................................................................................................................. 9

References .................................................................................................................. 9

ARES Probability Margins Management Process

Page 2

Executive Summary

System can be viewed as a combination of functions

or subsystems. Interactions between functions are an

essential part of the overall design. Through function

interdependencies, function margins are affected by

changes in margins of other interrelated functions.

To optimize a system with respect to performance

and margins, it is necessary to model the effects of

these margin interdependencies, so both baseline and

proposed margin optimizations can be properly

assessed.

An effective PMM process requires the collaboration

with system and subsystem leads, experts and subsystem managers, to determine the appropriate

Technical Performance Parameters (TPPs), margin

interdependencies and the associated margin

sensitivities. This includes regular reports and

recommendations made to the margins manager in

order to aid in responsible margin reallocation and

optimization of the system.

The Probabilistic Margin Management (PMM)

process provides a number of benefits compared to

traditional margin management that are designed to

aid program management throughout the entire

system development process.

Margins are uniquely and precisely defined by a

quantitative metric eliminating subjectivity

This process allows for complete margin

management by treating each margin as a

“bankable resource” that can be used in a tradeoff process to optimize cost, schedule and

performance goals

PMM quantifies the major technical requirement

drivers,

Optimizes each requirements margin to improve

the success of meeting project goals and

objectives

Enhances the program management decision

process clarifying the interactions between cost

schedule and technical risks.

Problem Statement

The design and development of any complex

multidisciplinary system is inherently difficult and

ARES Probability Margins Management Process

uncertain because no single person has all of the

detailed knowledge required for all disciplines. It is

therefore necessary to establish and maintain a set of

margins for all system requirements in order to

properly account for the changes with a known

value, changes with an unknown value and changes

that you do not even know about (the unknown

unknowns). Today most margins are established

using discrete values derived from historical data,

expert judgment, or taken directly from industry

standards. There are two primary faults with this

approach. The first is that margins themselves are

uncertain and are not universal across various

systems. As a result, incorrect margins are often

utilized when important programmatic decisions are

being made during all parts of the program life cycle.

Secondly,

margins

cannot

be

established

independently. The existence of interactions and

uncertainty within complex systems must be

accounted for otherwise the total impact will be

underestimated. The process depicted in Figure 1

illustrates how the margin interactions are developed

and the continuously managed through the design

process.

Define Technical

Performance Parameters

Develop Margin

Interactions Matrix

Develop/Revise

Transfer Function

Distributions

Update TPP &

Margin Estimates

Assess Design

Changes &

Maturation

Figure 1. ARES PMM Process Flowchart

For example, the program manager maintains a set of

margins for each subsystem in case of unexpected

problems. As system development advances the

program manager can allocate additional or

redistribute the available margin based on current

design information. The PMM process can help

program managers make better decisions about the

effects of allocating margin and develop an

Page 3

optimized distribution that maximizes the likelihood

of meeting all requirements.

The ARES’ PMM process can help to develop

greater confidence in the initial margin allocation,

provide a greater understanding of the impacts of

interactions on the system and help the manager

make better decisions about the reassessment of TPP

margins.

ARES Solution

The ARES’ PMM process provides a unified system

level approach to TPP margin control. The PMM

process is a comprehensive and practical method for

capturing the effects of margin interactions as well

as the probabilistic and unique nature of margin

assessment. ARES’ PMM process supports the

assessment of baseline margins and optimization of

the major sensitivity effects by allowing the margin

estimates to be expressed in terms of a statistical

confidence similar to the way risk is managed.

For accurate margin management, it is also

necessary to capture the probabilistic nature of

margin estimates and the corresponding interactions.

System margins estimates can be suitably

represented as probability distributions. When

margin estimates are developed, the estimate can be

characterized as having a quantified amount of

confidence for achieving a specific value.

Merits of ARES Solution

The benefits of ARES PMM process can be

summarized as follows:

Probabilistic instead of deterministic providing

an alternative method when adequate information

is not available.

Account for complex interactions generally not

readily available

Provide program management the ability to make

informed decisions regarding the system’s ability

to meet TPP requirements

Use sensitivity analysis to show the TPPs

affected most by a margin change

Determine optimal margin allocation which

results in the greatest confidence of achieving all

requirements.

Technical Description

ARES continuous margins management process is

outlined in Figure 1. To perform an interdependency

assessment, it is first necessary to define the TPPs to

be modeled. A Margin Interaction Display is then

created to define which margins interact with one

another. Transfer functions for each interaction are

developed through subject matter expert interviews

and historical data analysis. TPP estimates are

gathered to complete the model. This baseline

model is used to assess design modifications and

maturation and is continuously updated according to

the latest TPP estimates.

PMM is used to evaluate a system through a

mathematical model which captures the effect of

probabilistic function margin interactions. Normal

distributions are used to represent either margin or

Current Best Estimate (CBE) distributions. PMM

can be used at either the system-level or componentlevel, because the margin interaction calculations can

be performed on any integrated system, with the

resulting margins rolling up into the overall margin

calculation of the system. This process is similar to

that used to perform a Probability Risk Assessment

(PRA).

Matrix algebra is employed to solve for cascading

margin effects due to interactions. The core of the

mathematical solution is provided in the following

equation. Using matrix algebra to build the vector

dependencies and incorporating them into a single

equation, the resulting margin effects to the N order

can be determined.

{Σ(∆𝑀)} = ([𝐶] + [𝐶][𝐶] + ⋯ + [𝐶]𝑁 ){∆𝑀0 }

Where:

{∆𝑀0 } = vector of the initial margin change

{Σ(∆𝑀)} = the total margin change after N orders of

effect are calculated

[C] = a square matrix of margin transfer functions

ARES Probability Margins Management Process

Page 4

The interaction effects continue regardless of how

many orders of effect are considered. But for

practical cases with realistic transfer functions, the

additional margin change effect decreases as the

number of order effects considered increases. Since

there is a point of diminishing returns to the

calculation at higher orders, a maximum order of

effect is chosen (typically 5) as providing a

reasonable estimate of the effect, beyond which

further calculation provides minimal added value.

Detailed PMM Steps

Baseline Assessment

Define Functions

Capture Margin Estimates for each Function

Develop Margin Interaction Display

Capture Transfer Function Distributions

Perform Interaction Assessment for Baseline Case

Perform sensitivity assessments to

determine margin drivers

Refine Optimization

Optimization Assessment

Determine Optimization Criteria

margin rolling up into the margin calculation of the

overall system functions.

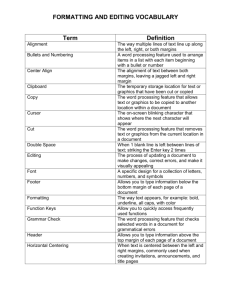

Step 2. Capture Margin Distributions

The PMM process is also designed to use

distributions on either known margins or the CBE of

design parameters. If CBE distributions are utilized,

they are transformed into margin distributions by

using the appropriate margin definition equation

relevant to each design parameter as shown below.

After the PMM assessment is performed, the

resulting CBE design parameters can be determined

by using the inverse of the margin definition

equations:

𝐶𝐵𝐸 𝑀𝑎𝑟𝑔𝑖𝑛 =

𝐶𝑢𝑟𝑟𝑒𝑛𝑡 𝐵𝑒𝑠𝑡 𝐸𝑠𝑡𝑖𝑚𝑎𝑡𝑒 − 𝑅𝑒𝑞𝑢𝑖𝑟𝑒𝑚𝑒𝑛𝑡

𝑅𝑒𝑞𝑢𝑖𝑟𝑒𝑚𝑒𝑛𝑡

Margin-related input parameters are represented as

Normal distributions to account for the level of

uncertainty in the analysis, as shown in Figure 3.

Normal distributions are used to represent margin

and CBE distributions, consistent with industryaccepted design development procedures such as

Design for Six Sigma [1].

Modify resources or requirements

Perform Interaction Assessment for Optimization Case

No

Assess Optimization Results:

Adequate?

Yes

Optimization Complete

Figure 2. ARES PMM Flowchart

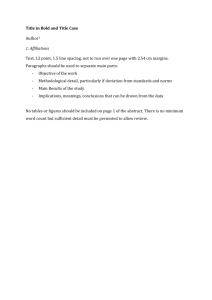

Step 1. Define Functions

PMM can be used to analyze any level of system

detail. As with any analytical modeling effort, this

analysis provides the most benefit if it is performed

at the level of detail which content specific decisions

are made.. The methodology can also be performed

at varying levels of detail based on the fidelity of

information available for each subsystem. PMM

allows use of different levels of detail, because the

margin interaction calculations can be performed at

subsystem levels, with the resulting subsystem

ARES Probability Margins Management Process

Figure 3. Sample Input Distribution

Step 3. Margin Interaction Display

It is necessary to have a method of graphically

capturing the interactions of the margins of

functions. Figure 4 demonstrates how PMM captures

the interactions of margins for any system. The red

nodes on the matrix indicate interactions among the

Page 5

system-level functions. The interactions flow in a

clockwise direction. For instance, a change in the

Thermal Management margin has an effect on the

Power, Propulsion and Gross Vehicle Weight

(GVW) margins and the GVW margin effects the

Tank Structure margin. This Margin Interaction

Display (MID) is tiered such that the margin

interactions within individual functions can also be

described with a MID.

Tank Structure

terms of the relative effects of margins. For the

specific case of the same input element as the output

element, the value of the transfer is zero, since the

margin change of an element will have no direct

additional change on the input element. The

interactions are captured in a square matrix in order

to facilitate the mathematical calculations.

The ARES methodology utilizes a transfer function

which is expressed as changes in margin. The

following are advantages of using changes in margin

as the inputs and outputs of the transfer functions.

Thermal

Management

Power

Propulsion

GVW

Volume

Figure 4. Margin Interaction Display

Step 4. Transfer Function Distributions

After identifying which functions and elements have

margin interactions for the system or subsystem of

interest, it is necessary to quantify the amount of

interactions. The margin interactions are quantified

in terms of transfer functions. The transfer function,

a concept used in block diagram system modeling, is

defined as the ratio of an elemental block's output to

its input. To evaluate the output response of an

element, the input is multiplied by the value of the

transfer function ratio. This provides an analytical

tool that is easily integrated into a model based

system engineering paradigm.

Parameters are expressed as dimensionless ratios

to provide consistent measuring

Transfer functions are captured in terms of the

effect of margin change which is more practical

than capturing transfer functions as complex

mathematical relationships

Margin interaction matrices that use margin

change as inputs and outputs are rolled-up into

higher level system margin interaction matrices.

The Transfer Function Relationship Diagram,

provided in Figure 5, is utilized to help visualize the

transfer functions in terms of their relationship to the

input and outputs of the system elements.

Tank Structure

Tank Structure

ARES Probability Margins Management Process

Power

2

Propulsion

3

GVW

4

Volume

5

6

Δ M1

Δ M1

Δ M2

Δ M6

1

Δ M2

Thermal

Management

Δ M1

2

Power

Δ M3

Δ M3

Δ M2

Δ M4

3

Propulsion

Δ M4

Δ M4

Δ M4

Δ M4

Δ M1

Δ M2

Δ M3

Δ M5

Δ M5

Δ M1

Δ M5

Δ M5

Δ M5

Δ M1

Δ M2

Δ M3

Δ M4

Δ M6

4

GVW

ARES margin interaction transfer function ratios are

defined as the direct change in margin of the output

parameter due to a change in the margin of the input

parameter. The value of this transfer function can be

captured practically for an output element as a

function of a different input element, by thinking in

Thermal

Management

1

5

Volume

Δ M6

Δ M6

Δ M6

Δ M1

Δ M3

Δ M5

6

Figure 5. Transfer Function Relationships

Page 6

The system and subsystem transfer functions are

both expressed as Triangular distributions, which are

defined by the lowest, the most likely, and the

highest possible Transfer Function ratios and are

shown in Figure 6 [3].

outputs are the distributions of margins for each of

the system functions (including interactions) and a

table providing the change in margin for each

parameter based on the change in margin of the other

parameters. The baseline margin distributions will

vary from the input modified optimum margin

distributions due to the interaction effects between

distributions that are not initially considered.

The remaining steps in the PMM process are

designed to take the margin interaction assessment

provided in Steps 1 to 5 and optimize the allocation

of margin. An optimized solution is defined as the

design which has the maximum probability of

meeting all of the requirements.

Figure 6. Notional Transfer Function Distribution

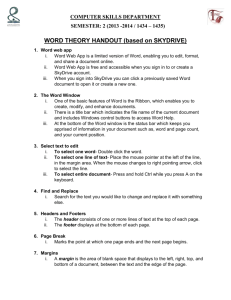

The transfer function distribution estimates are

developed during interviews with system and

subsystem experts in order to establish the bounds of

each Triangular distribution. These results are then

organized into a Transfer Function Matrix similar to

the one provided in Figure 7.

Input

Thermal

Management

Power

Propulsion

GVW

Volume

Tank

Structure

0

.09 .10 .11

0

.09 .10 .11

.09 .10 .11

.09 .10 .11

Thermal

Management

.09 .10 .11

0

.09 .10 .11

.09 .10 .11

.09 .10 .11

0

Power

0

0

0

.09 .10 .11

.09 .10 .11

.09 .10 .11

Propulsion

0

0

.09 .10 .11

0

.09 .10 .11

0

GVW

0

0

0

.09 .10 .11

0

.09 .10 .11

Output

Tank

Structure

Volume

0

0

0

0

.09 .10 .11

0

Figure 7. Transfer Function Matrix (notional)

Step 5. Monte Carlo Simulation

Monte Carlo simulation for the baseline margins is

performed utilizing a large set of trials. The primary

ARES Probability Margins Management Process

Step 6. Optimization Criteria

It is necessary to define the goals of the optimization

effort. The definitions should be stated in terms of

the resulting margins of the system. Each function

may have different optimization requirements

depending on whether it is characterized as a target

or a constraint. A target function margin is the

desired function margin to optimize. A constraint

function margin is a function margin which must not

exceed a certain threshold, or which must be within a

certain bound.

Step 7. Sensitivity Assessments

In order to optimize the margins it is necessary to

understand the system functions and subsystem

elements which have the greatest impact on the

margins. In particular it is necessary to understand

how each of the function and element margins

affects the target margin. It is also necessary to

understand how each of the function and element

margins affects margins which are primary

constraints.

Tornado effect diagrams are useful for establishing

sensitivity relationships by providing a ranking of

the design factors that have the greatest influence on

the variability of a particular variable. Figure 8

shows a notional tornado effect diagram. The use of

this type of diagram allows decision makers to

quickly assess which factors have the greatest impact

on the design parameter of interest.

Page 7

final assessment provides the margin confidence

levels for the final optimized configuration.

Step 10. Assess Optimization Results

The results of the optimization are compared to the

optimization objective, to determine if the results

meet the requirements, or if further refinement of the

optimization is required. In order for the

optimization to be accepted as final, the optimization

goals of the target margins must be achieved, and the

constraints on the other margins must not be

violated. Once these requirements are achieved the

optimization is complete.

Figure 8. Sensitivity Analysis (notional)

Step 8. Alter Resources/ Requirements

The results of the tornado diagram for a target

optimization margin show the amount of margin

increase which will result from a change in another

function. If driving TPPs are identified which

provide a beneficial increase in the target margin, but

which have an excess margin themselves, then the

margin of the driving TPPs can be changed to cause

an optimum improvement in the target TPP. The

driving TPP’s margin can be changed through either

a change in the resource or the requirement for the

function. The driving TPP’s change to its resource

or requirement which is required to achieve its

change in margin is calculated through the margin

calculation definition.

Step 9. Interaction Assessment

Monte Carlo simulations for the baseline margins are

performed utilizing a large set of trials. The primary

outputs of the interaction assessment are the

distributions of margins for each of the system

functions (including interactions) as done in Step 5.

The baseline margin distributions vary from the

input modified optimum margin distributions due to

the interaction effects between distributions. This

ARES Probability Margins Management Process

Step 11. Refine Optimization

If the results of the optimization either do not

achieve the margin goals for the target margins or

violate the constraints of other margins, the

optimization must undergo a further iteration. At this

point the process loops back to step 7. In this case

the sensitivity studies are utilized to determine what

parameter(s) will have the largest desired effect on

the optimization variable.

PMM Implementation

The ARES PMM process reduces the error

associated with arbitrarily assigning system and

subsystem margins and allows the project margins

manager to make better decisions about reallocation

of margins. This process can be integrated into the

traditional system engineering process or a model

based process using the existing system engineering

tools and databases.

PMM also probabilistically identifies untenable

requirements or margin allocations earlier in the

design/development cycle which allows the manager

to better control system scope or cost growth. By

addressing the design margins or requirement

problems early in the life of the system the cost of

addressing the design inconsistencies is dramatically

reduced.

As described in the Technical Description section

above, ARES collaborates with the system and

subsystem managers to determine the appropriate

TPPs. ARES interviews system and subsystem leads

and experts to determine and develop suitable

interaction and transfer functions. ARES then

Page 8

develops the margins baseline and presents a

standard margins report to the system and (as

appropriate) subsystem managers. Additional

guidance is provided which includes advising and

assisting management in the organization and the

prioritization of individual margins for optimization.

ARES has effectively implemented the PMM

process in support of Lockheed Martin’s System

Engineering group during PDRR by writing the

Margins Management Plan and facilitating the

system-level margins management activities and

coordinating activities across the ground and space

segment. Additionally, ARES utilized the PMM

process to estimate the uncertainty in the initial IPT

mass estimates for Northrop Grumman. Including

establishing confidence levels for the base level

estimates, establish driving factors for all margins,

and determined the margin sensitivity to key

assumptions.

References

1. Yang, K., EI-Haik, B., Design for Six Sigma: A

Roadmap for Product Development, McGraw-Hill,

2003

2. Billinton, R., Allan, R., Reliability Evaluation of

Engineering Systems: Concepts and Techniques,

Second Edition, Plenum Press, 1992

3. Elsayed, E., Reliability Engineering, Addison

Wesley Longman, 1996

Conclusion

The PMM process provides several distinct benefits

that aid program management throughout the entire

system development process. Utilizing the ARES

PMM process, decision makers are able to gain a

better understanding of how the allocation of

margins impacts the system and determine how

margins should best be allocated to provide the

greatest confidence that all requirements will be

achieved. Additionally, uncertainty distributions are

utilized to establish which requirements are at the

greatest risk of being violated and require the

greatest initial margin reserves. As a result of

implementing this process, better decisions are made

up front which, in turn, reduces the number of design

changes required during later design phases, and

reduces the risk associated with cost-overruns and

slipped schedules.

ARES Probability Margins Management Process

Page 9