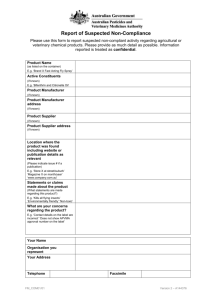

DOCX 438 KB - Australian Pesticides and Veterinary Medicines

advertisement