Patchy Janus particles with tunable roughness and

advertisement

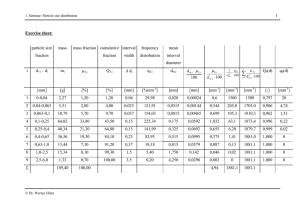

Supplementary Information for K.B. Shepard et al. “Patchy Janus particles with tunable roughness and composition via vapor-assisted deposition of macromolecules” Particle materials and synthesis PS particles were synthesized according to the procedures detailed by Zhang et al.1 Particle sizes are modified from the above procedure by varying the relative concentrations of the ammonium persulfate initiator and monomers. Silica nanoparticles were synthesized a classical Stober technique2 in which 10mL NH3 was mixed well in 10mL water and 74mL ethanol, then 5.6 mL tetraethyl orthosilicate was added and stirred for 12 hr. Precursor particle film preparation Prior to coating, microscope glass slides were cleaned by heating in piranha acid (4:1 H2SO4:H2O2,) at 95 ºC for 30 min, then rinsed and stored in DI water. Suspensions of PS or silica nanoparticles (1-9%wt) in a water/methanol solution (3:1 – 1:1) were immersed in a sonic bath for 15 minutes prior to film casting. Precursor particle monolayers were coated onto the glass slides via a programmable syringe pump following the procedure of Prevo and Velev.3 A 50 μm image of a typical silica particle monolayer is shown in the figure below, taken with a 3D laser microscope (SI Figure 1). The bright spots represent areas where more than a monolayer of SI Figure 1: Laser microscope image of a Silica particles has deposited. Even coverage particle monolayer formed by drag coating. and large areas (grain size >10μm) of hexagonally-packed particles was observed. After sonication of either precursor or Janus particle films, examination of the substrate with the laser microscope showed that nearly all particles were removed, indicating that particle immobilization is easily reversed by sonication in water. MAPLE deposition Amorphous PMMA (~15 kg/mol molecular weight) or semicrystalline PEO (4.6 kg/mol) was dissolved in chloroform (0.1% by weight). The details of the MAPLE deposition process have been described in detail in previous papers.4 During deposition, the glass substrate was held at a constant temperature of 27°C, unless stated otherwise. Though not discussed in the paper, the size distribution of the polymer nanodroplets could be manipulated by varying the composition of the MAPLE target solution, as reported in our previous work.4 This provides another method to systematically tune the surface properties of the Janus particles. Janus particle post-fabrication annealing study PMMA/silica patchy Janus particles were fabricated via MAPLE deposition with a substrate temperature of 27 °C, then underwent 1 hour annealing at 130°C. The morphology is very different than that of particles fabricated with a substrate temperature of 130°C, in that most of the polymer now forms polymer bridges between particles, instead of wetted droplets at the particles’ surfaces. SI Figure 2: AFM height and phase images of post-annealed PMMA/silica patchy Janus particles. References: (1) Zhang, L.; D’Acunzi, M.; Kappl, M.; Auernhammer, G. K.; Vollmer, D.; van Kats, C. M.; van Blaaderen, A. Hollow Silica Spheres: Synthesis and Mechanical Properties. Langmuir 2009, 25, 2711–2717. (2) Stöber, W.; Fink, A.; Bohn, E. Controlled Growth of Monodisperse Silica Spheres in the Micron Size Range. J. Colloid Interface Sci. 1968, 26, 62–69. (3) Prevo, B. G.; Velev, O. D. Controlled, Rapid Deposition of Structured Coatings from Micro- and Nanoparticle Suspensions. Langmuir 2004, 20, 2099–2107. (4) Shepard, K. B.; Arnold, C. B.; Priestley, R. D. Origins of Nanostructure in Amorphous Polymer Coatings via Matrix Assisted Pulsed Laser Evaporation. Appl. Phys. Lett. 2013, 103, 123105.