Conducting a Resource Assessment

advertisement

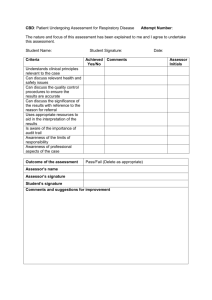

Conducting a Resource Assessment 1. Introduction 2. Materials Assessments 2.1 Materials assessment framework 2.2 Conducting the assessment 2.3 The materials assessment report 3. Energy Assessments 3.1 Energy assessment framework 3.2 Conducting the assessment 3.3 The energy assessment report 4. Implementation Development 1. Introduction: Resource Assessment This information was developed to support the Resource Assessment Grants, 2015/16. The program encourages businesses to understand their energy and/or materials use and intensity, to identify opportunities to reduce energy and/or materials use and waste generated, and/or improve productivity. For example: Produce more product or service with the same amount of energy or materials by improving resource efficiency or productivity, businesses can reduce their environmental impacts and save money. The assessment approach allows the identification of the greatest impact areas for businesses, to permit targeted actions in the areas where the best opportunities to save resources and money exist. The Conducting a Resource Assessment information has been developed: 1. To assist businesses who are considering applying for funding to carry out an energy or materials or materials and energy assessment 2. For consultants (assessors) to check the minimum requirements for Resource Assessment Grants, 2015/16. This information sets the guidelines, standards and the minimum expectations for both the completion of the resource assessments and the resource assessment reports. Assessments that do not satisfy these requirements will not be eligible for funding. Further information on the Resource Assessment Grants, 2015/16, including eligibility criteria and application forms, visit http://www.sustainability.vic.gov.au/resource-assessment-grants P a g e 1 | 10 2. Materials Assessments 2.1 Materials assessment framework A materials assessment aims to identify opportunities to reduce materials use and materials costs. The materials assessment guidelines are based on mapping the flow of materials into and through a business. This will enable the baseline materials efficiency to be calculated for the high value materials and identify where the major losses are occurring in the business’ processes. The materials assessment will also identify the primary waste streams and determine opportunities for reducing material use and material cost. ‘Materials’ includes raw materials, stock, produce, stationery or other products that are purchased by a business to produce their products or services. Materials assessments consider all material inputs into a business and how these interact with the production of finished goods/services. They map the flows of materials into and through a business and can be measured in quantities or dollar value or both. The aim is to reduce spoilage, waste and unproductive activity. The result is more efficient use of purchased materials, more up time of plant and equipment, more productive labour and less waste to landfill. Benefits of a materials assessment Given that material costs are often the largest business cost next to labour, getting more from what a business buys makes good business sense. Materials efficiency enables a business to: Measure flows of materials through the production process Know how much material is used and how much waste or spoilage is generated per unit of product Know the ‘what, where and why’ of waste/materials Understand the true cost of waste to the business Know how much this waste costs your business to produce and manage Identify how to improve efficiency and reduce waste Develop and implement systems to improve and monitor resource efficiency Ensure that the maximum amount of product (and value) is obtained from the materials used in production; and Reduce costs P a g e 2 | 10 What does a materials assessment provide? Businesses who undertake a materials assessment will be provided with a list of suitable recommendations for improving their materials efficiency, ranked according to priority. The recommendations will be developed in agreement with the business and the consultant (assessor), and outline the best actions the business can undertake to reduce material use and generated waste and save money. The prioritised actions will include implementation costs and expected savings, and an implementation plan to an accuracy of +/- 20 %. The materials assessment will give the business a clear understanding of materials flow into and through the business. The materials assessment establishes a current baseline condition from which the performance of the business can be measured. Note these assessments are not limited to the completion of a traditional waste audit. However, the identification of waste streams will be critical to assist assessors to identify and quantify/value materials flow into and through the business. 2.2 Conducting the assessment Businesses will be responsible for selecting an assessor to undertake the materials assessment. The assessor will look at major material inputs (preferably by weight, if data is available, or in dollar terms) coming into the business, flowing through and leaving the business as final products, coproducts or waste. At a high level this involves: Gathering historical data and costs of key material inputs Mapping and quantifying material flows (either as volumes, weight or dollar amounts ) from supply through the various sections of production and services, and out as waste Calculating material efficiencies of products and processes based on the data Investigating opportunities for reducing material use and material costs The following diagram provides an overview of materials flow into and through a business and where the opportunities to improve efficiencies exist. P a g e 3 | 10 Overview of materials flow into and through a business Products (or services) OUT Materials IN Waste material at each stage of production of business’ products or services (the further along process line, the higher the ‘real cost’ of waste) Total waste OUT What should an assessment include? The materials assessment should consider all aspects of the business’ operations where materials inputs (raw materials, stock, products) occur, including: o Suppliers o Warehouse/storage o Production o Administration and sales o Waste production and collection However the assessment will usually focus on the key material/s i.e. the high quantity and/or high cost materials. What constitutes ‘materials’? Materials in manufacturing and non-manufacturing operations include: Inputs Process stage (wastes) Raw materials Packaging Stock Stationery Chemicals Produce Components Dust Unreacted materials By-products Trimmings Scrap Rags Gloves Consumables e.g. moulds, printer cartridges Off-cuts P a g e 4 | 10 Output stage (wastes) Other (wastes) Outputs Products (on specification) Off-specification products Discounted stock Damaged stock Contaminated raw materials Surplus raw materials Building/demolition rubble Scrap part/plant Administration e.g. paper, toner cartridges Organics e.g. garden materials, food scraps Transport packaging waste Finished products Key activities in a materials assessment The following activities should be carried out as part of a materials assessment: 1. Collection of data This will involve gathering information from the business on the past use of raw materials, the costs of input materials, suppliers information, cost of waste disposal, any previous material or waste assessments, plans for expansion or new processes. 2. Undertake a materials input survey This will provide a complete picture of the types and quantities/values of the key materials entering the business. It will identify the high value input materials which can be used later in the mapping process to identify costly inefficiencies. 3. Analysis of production processes for products or services This will look at all stages in the production processes to identify where materials are used and the quantities, waste outputs at each stage and opportunities for efficiency improvements, especially for high value materials. 4. Undertake a waste survey This will identify the composition, sources, classification, quantities and destination of waste materials generated. This information will help provide a picture of the real cost of waste, i.e. the value of the raw materials lost, the cost of collection/disposal of these materials, and the potential loss from not reusing or selling the ‘waste’ and therefore the opportunities for saving money. Note: Packaging waste should be included, but should be reported separately from the raw material waste that is generated on the site unless the packaging is produced on site. P a g e 5 | 10 2.3. The materials assessment report The assessment report will present the key findings from the materials assessment including, the total cost of materials (all or the key materials as appropriate), the purchase to disposal ratio and/or the true cost of waste and the material saving opportunities. The report will clearly identify where and how savings can be made, and quantify/value the savings. It will also include a set of recommended actions to maximise materials efficiency and cost savings ranked according to priority. Assessors must hold an on-site meeting to explain these recommendations to the business to ensure the actions are appropriate and achievable by the business, before the final report is delivered. Actions that are identified as best practice or good housekeeping that will reduce the cost of doing business should also be included in the assessor’s recommendations. The recommendations must include the “how to” of improving materials efficiency rather than just the “what”. Accuracy of the implementation costs and benefits of the recommendations should be within +/20%. Minimum requirements for the final assessment report The final assessment report should include the following elements as a minimum: Executive summary – including: o Total cost of materials or of key material/s o Total quantity of the key material/s (preferably in kg or tonnes) o Total cost expressed as a percentage of operating costs o The purchase to disposal ratio for the key wastes and/or the true cost of waste o The four or five key actions that make most business sense in terms of effectiveness, cost, ease of implementation and pay-back time, all presented in tabular form Introduction Background to the company and project, including a description of the key activities contributing to material use and waste generation Objectives of the assessment Scope of the assessment Assessment methodology Material use and waste generation profile for the baseline period, including: o Materials efficiency and waste generation key performance indicators o Data sources, and o An assessment of the level of accuracy of the data A table giving a list of actions/recommendations that could reduce material use and waste generation activities including: o A description of the action (see examples below) P a g e 6 | 10 o The impact of the action on material use and waste generation o The impact of the action on other organisational factors. This should cover the consequences of the proposed changes that will need to be addressed during implementation of the recommendations. For example, changes may need to be implemented during shut-down periods or additional labour, energy, water or space may be required o The cost savings, cost to implement the actions and indicative payback period o The agreed action table for the business, ranked according to priority o An action plan, including a clear description of the work program involved in implementing each recommendation o A summary of the findings, including recommendations for future investigation Ongoing data management and reporting template to allow future tracking and performance to be analysed Site layout and location plan Examples of material efficiency actions include: Inputs Processes Waste output Purchasing less raw materials or stock Purchasing more sustainable options or more sustainably sourced Purchasing materials that require less packaging and pallets from suppliers Purchasing locally to reduce transport costs Improving input material measuring & monitoring Improved batching Better layout and nesting Realigning processes Minimising material wastage by reducing stoppages, lengths of runs and offcuts Considering designing products and processes to reduce material used (dematerialisation) Reducing the regularity of office fit-outs and re-using furniture Reducing paper use in printing Reducing stages in delivering services Looking at opportunities for segregation for re-use and recycling Identifying the commercial value of waste materials Recycling organic materials Considering design products for ease of disassembly and recycling Renegotiating waste contracts P a g e 7 | 10 3. Energy Assessments 3.1. Energy assessment framework Resource Assessment Grants, 2015/16 aim to identify opportunities to reduce energy use and energy costs. Eergy assessments are based on the equivalent of a Type 2 Energy Assessment (Australian Standard AS/NZS AS3598.1:2014, AS/NZS AS3598.2:2014 and AS/NZS 3598.3:2014). The assessment will identify the sources of energy used (fuel, electricity, gas), the amount of energy supplied and consumed, and what the energy is used for. It will identify areas where savings may be made, recommend measures to be taken, and provide the business with an indication of costs, payback periods and potential savings for different energy efficiency measures. 3.2 Conducting the assessment Businesses will be responsible for selecting a consultant (assessor) to undertake the energy assessment. The following activities should be carried out as part of the energy assessment: 1. Identify any existing energy management practices and opportunities for improvements including: Analysis of energy used at the site over the last 12 months – provided as a total figure, as a percentage of site operating costs or as an energy intensity number Assess if the business is on the appropriate tariff Using sub-meters as both a management tool and to verify savings Establishing the potential for energy sub-meters to be used as both a management and savings verification tool Establishing the current level of business understanding of energy savings including the current reporting of site and key impact areas Identifying the commitment of senior management to energy efficiency practices and current energy saving actions 2. Determine and analyse energy consumption This involves a detailed description of where energy is used in the business including a breakdown of quantities of energy used, hours of operation and total annual costs for different equipment and processes. Potential areas of focus include: Lighting HVAC (heating, ventilation, air conditioning) systems Appliances Plant and equipment – e.g. compressors, boilers Process heating Refrigeration P a g e 8 | 10 3. Identify Opportunities Site visit to inspect site and plant and to interview key staff so to understand energy consumption under different circumstances Presentation of a draft list of opportunities to the organisation for discussion Identification and quantification of energy savings Identification of measures where additional data/investigation involving measurement would be required 3.3 The assessment report The assessment report will provide a list of suitable recommendations to improve energy efficiency, ranked according to priority. Assessors must explain these recommendations to the business to ensure the actions are best suited to their business, before the final report is delivered. The report will present energy saving opportunities, clearly identifying where savings can be made, how much that they cost to implement, and what savings can be made. It will include a set of recommended actions the business can undertake to maximise energy efficiency and cost savings. The report will also make recommendations on energy management practices, as appropriate. Accuracy of the implementation costs and benefits of the recommendations should be within +/20%. Minimum requirements for the final assessment report The final report should include the following elements as a minimum: Executive summary including: o Total cost of energy o Total cost of electricity and gas o Total cost expressed as a percentage of operating costs o The four or five key actions that make most business sense in terms of effectiveness, cost, ease of implementation, and pay-back time in tabular form Introduction Background to the company and project including a description of the key activities contributing to energy use Objectives of the assessment Scope of the assessment Assessment methodology Energy use profile for the baseline period, including: o Data sources, and P a g e 9 | 10 o An assessment of the level of accuracy of the data A table giving a clear breakdown of each energy saving opportunity/recommendation and providing detail where required. The table should include the following : o o o o o o o o o o o o Description of the option/recommendation How each action can be implemented Annual energy saving (electricity and gas) Other cost savings Total cost savings Annual cost saving as a percentage of total operating costs (to allow Sustainability Victoria to compare energy input against material input) Estimated implementation/capital costs Payback period Annual and lifetime greenhouse gas savings Victorian Energy Efficiency Target (VEET) scheme opportunities. (For more information, refer to the VEET fact sheets available on www.sustainability.vic.gov.au or visit www.veet.vic.gov.au) Other risks and considerations identified throughout the assessment process Ongoing data management and reporting template to assist the organisation in tracking their energy use Site layout and location plan 4. Implementation Development Once a business has completed a resource assessment, they may also be eligible to apply for funding to the Resource Assessment Grants, 2015/16 implementation bonus to carry out additional scoping work that is required to gain approval for the implementation of recommendations arising from the assessment report. Additional work may include: an option study, detailed feasibility study, purchase of monitoring equipment, detailed design including materials and mass flow analysis for the preferred option, development of a detailed business case, and technical and project management support. More information For further details on Resource Assessment Grants, 2015/16, visit: http://www.sustainability.vic.gov.au/resource-assessment-grants or queries regarding these guidelines, please email: resource.assessments@sustainability.vic.gov.au or phone: 1300 363 744 P a g e 10 | 10