etc2865-sup-0001-SuppData-S1

advertisement

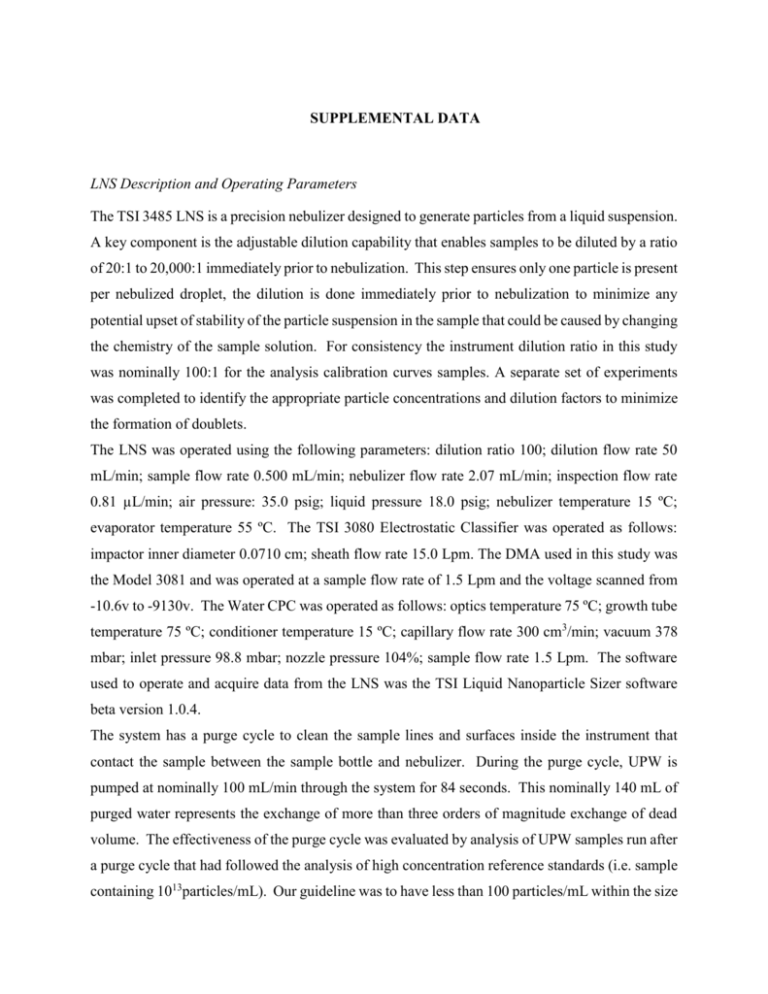

SUPPLEMENTAL DATA LNS Description and Operating Parameters The TSI 3485 LNS is a precision nebulizer designed to generate particles from a liquid suspension. A key component is the adjustable dilution capability that enables samples to be diluted by a ratio of 20:1 to 20,000:1 immediately prior to nebulization. This step ensures only one particle is present per nebulized droplet, the dilution is done immediately prior to nebulization to minimize any potential upset of stability of the particle suspension in the sample that could be caused by changing the chemistry of the sample solution. For consistency the instrument dilution ratio in this study was nominally 100:1 for the analysis calibration curves samples. A separate set of experiments was completed to identify the appropriate particle concentrations and dilution factors to minimize the formation of doublets. The LNS was operated using the following parameters: dilution ratio 100; dilution flow rate 50 mL/min; sample flow rate 0.500 mL/min; nebulizer flow rate 2.07 mL/min; inspection flow rate 0.81 µL/min; air pressure: 35.0 psig; liquid pressure 18.0 psig; nebulizer temperature 15 ºC; evaporator temperature 55 ºC. The TSI 3080 Electrostatic Classifier was operated as follows: impactor inner diameter 0.0710 cm; sheath flow rate 15.0 Lpm. The DMA used in this study was the Model 3081 and was operated at a sample flow rate of 1.5 Lpm and the voltage scanned from -10.6v to -9130v. The Water CPC was operated as follows: optics temperature 75 ºC; growth tube temperature 75 ºC; conditioner temperature 15 ºC; capillary flow rate 300 cm3/min; vacuum 378 mbar; inlet pressure 98.8 mbar; nozzle pressure 104%; sample flow rate 1.5 Lpm. The software used to operate and acquire data from the LNS was the TSI Liquid Nanoparticle Sizer software beta version 1.0.4. The system has a purge cycle to clean the sample lines and surfaces inside the instrument that contact the sample between the sample bottle and nebulizer. During the purge cycle, UPW is pumped at nominally 100 mL/min through the system for 84 seconds. This nominally 140 mL of purged water represents the exchange of more than three orders of magnitude exchange of dead volume. The effectiveness of the purge cycle was evaluated by analysis of UPW samples run after a purge cycle that had followed the analysis of high concentration reference standards (i.e. sample containing 1013particles/mL). Our guideline was to have less than 100 particles/mL within the size range of 20 to 230 nm. Samples containing high levels of surfactant and/or very high solids concentration (i.e. 50 wt%) can leave residuals on the soft plastic tubing in the LNS that shed particles. In some cases our guideline could not be achieved and the plastic tubing in the LNS had to be replaced. Description of Water Matrices Because non-volatile material(s) in the sample and dilution water will become aerosol after nebulization and drying, the LNS system requires high purity water to reduce potential background interference. UPW was generated using a custom built, semiconductor grade water purification system (Smith Engineering Inc. Chaska, MN) that used di-ionized water as a feed. The DI water has a nominal resistance < 18.2 Mohm-cm. The system is comprised of deionized (DI) water as a source of water, a storage tank with a nitrogen blanket to prevent the absorption of carbonate from gaseous CO 2, a re-pressurization pump to provide up to 19 L min-1 of recirculation flow to continuously cycle the water through the system and achieve a pressure of 60 PSI. (Note the TSI 3485 system requires this input UPW pressure). A nominal 0.45 µm filter is used for gross particulate removal. A UV light system with a portion of energy in the 185 and 254 nm regions, to reduce total organic carbon (TOC) and control micro organisms, respectively. Primary and final mixed-bed ion exchange beds to remove dissolved contaminants from the water. A 0.1 µm pre-filter followed by a 0.02 µm final filter for very fine particulate removal. High purity Teflon tubing, valves, and fittings used downstream of the deionizers to minimize leaching of non-volatile residue into the UPW. The suitability of the UPW is evaluated by analyzing the UPW on the LN-DMA-CPC system and measuring the number concentration of particles in UPW in the range of 20 to 230 nm. UPW having less than 100 particles/mL in the 20-230 nm particle size range was suitable for the work done in this study. This UPW is among the cleanest water that is technically possible to achieve in lab. The AM and DM were prepared by ERA Labs (Duluth, MN). The AM was prepared by adding the following mass of each component to 500 mL of water from a Milli-QTM water purification system: 6.08 g MgCl2·6H2O, 2.20 g CaCl2·2H2O, 12.75 g NaNO3, 7.35 g MgSO4·7H2O, 0.522 g K2HPO4, 7.50 g NaHCO 3, 92.8 mg H3BO3, 208.0 mg MnCl2·4H2O, 1.64 mg ZnCl2, 79.9 mg FeCl3·6H2O, 0.714 mg CoCl2·6H2O, 3.63 mg Na2MoO4·2H2O, 0.006 mg CuCl2·2H2O, 150.0 mg Na2EDTA·2H2O, and 1.196 mg Na2SeO4. The DM (also known as lab reconstituted water (LRW)) was prepared by adding the following mass of each component to 100 L of deionized water: 20.0 g CaSO4·2H2O, 20.0 g MgSO4, 20.0 g NaHCO3, and 0.30 g KCl. The detailed chemical composition of the groundwater and wastewater was not determined. The groundwater was sourced from a well in Washington County, MN from an aquifer known to contain carbonate materials. The wastewater was obtained from the effluent of a manufacturing plant in Decatur, Al. The plant has primary and secondary wastewater treatment and is used to treat water originating from chemical manufacturing and sanitary sewers. Determination of particle concentration The particle number concentrations for individual reference standards were either provided by the vendor or determined mathematically using weight percent and particle geometry. The 20 nm, 40 nm, and 60 nm PSL standard particle concentrations were calculated using experimentally determined % dry weights. The 100 nm and 200 nm PSL standard particle concentrations, as well as the 18 nm, 30 nm, 50 nm and 100 nm silica standard particle concentrations were calculated using the solids concentration reported on the certificates of analysis provided by the vendors. The particle concentration of the 28 nm silica standard from TSI was calculated based on the volume weighted particle concentration provided by the vendor. Finally, the silver and gold particle concentrations were provided by the vendor NanoComposix. Concentration Calibration Curve Data A series of solutions were prepared in each media using each standard material (i.e. matrix matched standards) to be used to prepare calibration curves. The calibration curves for SiO 2 in the six media validated are shown in the Figure S.1. The slope and intercepts of these curves are then used to provide a response factor that is specific for the particular material in the particular matrix. The slope, intercept, and R 2 values for all the calibration curves are provided in Table S.1 1015 a. SiO2 in Algae Media 1014 b. SiO in UPW 2 Actual Concentration (#/mL) Actual Concentration (#/mL) 1014 1013 1012 SiO2 FMT 18 nm SiO2 FMT 30 nm SiO2 TSI 28 nm SiO2 PolySci 50 nm SiO2 PolySci 100 nm 1011 1010 1013 1012 1011 SiO2 FMT 18 nm SiO2 FMT 30 nm SiO2 TSI 28 nm SiO2 PolySci 50 nm SiO2 PolySci 100 nm 1010 109 109 109 1010 1011 1012 1013 1014 1015 Blank-corrected Measured Concentration (#/mL) 109 1010 1011 1012 1013 1014 Blank-corrected Measured Concentration (#/mL) 1015 c. SiO2 in Daphnia Media Actual Concentration (#/mL) 1014 1013 1012 1011 1010 SiO2 FMT 30 nm SiO2 PolySci 100 nm 109 109 1010 1011 1012 1013 1014 1015 Blank-corrected Measured Concentration (#/mL) Figure S.1 Concentration Calibration curves for SiO2 standards prepared in the three test media. Table S.1 Slope, intercept, and R2 values for UPW, AM, and DM concentration calibration curves Ultra Pure Water (UPW) 2 Algae Media (AM) Slope Intercept FMT 30nm SiO 2 1.1349 -1.4268 1.0693 -0.8118 1.0616 -0.4269 r 0.9842 0.9998 0.9993 1.2943 1.2534 1.0235 Polysciences 50nm SiO 2 1.0001 0.3679 0.9972 Polysciences 100nm SiO 2 0.9648 0.9480 0.8929 0.9731 1.0045 0.9567 0.7852 Material Slope Intercept FMT 18nm SiO 2 TSI 28nm SiO2 Thermo 20nm PSL Thermo 40nm PSL Thermo 60nm PSL Thermo 100nm PSL Thermo 200nm PSL 1.2752 0.1835 -0.0209 0.7542 2.7324 Daphnia Media (DM) 2 2 -3.3866 -3.3676 -0.2047 r 0.9706 0.9854 0.9979 1.1340 -1.8555 0.9937 0.9965 0.2283 0.9988 N/A 2 N/A 2 N/A 2 0.9976 0.9791 0.5669 0.9983 0.9873 0.3489 0.9986 0.9983 0.9986 0.9988 0.9950 0.9910 N/A 1 N/A 1 N/A 1 N/A 1 N/A 1 N/A 1 0.9728 1.0003 0.9838 0.9702 0.1111 -0.0398 0.3000 0.5665 0.9997 0.9994 0.9966 0.9633 N/A 1 N/A 1 N/A 1 1.0174 0.9732 0.9860 -0.3517 0.2875 0.2769 0.9986 0.9965 0.9675 1 Sample concentrations less than 3 times blank levels 2 One-point calibration Slope Intercept r N/A 1 N/A 1 N/A 1 1 1 N/A 1 N/A N/A Table S.2 Slope, intercept, and R2 values for DW, PW and WW concentration calibration curves Drinking Water (DW) Process Water (PW) 2 Wastewater (WW) 2 2 Material Slope Intercept r Slope Intercept r Slope Intercept r FMT 18nm SiO2 N/A 1 N/A 1 N/A 1 N/A 1 N/A 1 N/A 1 N/A 1 N/A 1 N/A 1 TSI 28nm SiO2 N/A 1 N/A 1 N/A 1 N/A 1 N/A 1 N/A 1 N/A 1 N/A 1 N/A 1 FMT 30nm SiO2 Polysciences 50nm SiO2 Polysciences 100nm SiO2 N/A 1 N/A 1 N/A 1 N/A 1 N/A 1 N/A 1 N/A 1 N/A 1 N/A 1 N/A 1 N/A 1 N/A 1 N/A 1 N/A 1 N/A 1 0.97675 0.459903 0.998966 1.024553 -0.09137 1.034017 -0.33696 0.999639 0.99816 0.97675 0.459903 0.998966 Thermo 20nm PSL N/A 1 N/A 1 N/A 1 N/A 1 N/A 1 N/A 1 N/A 1 N/A 1 N/A 1 Thermo 40nm PSL 1 1 1 1 1 1 1 1 N/A 1 Thermo 60nm PSL Thermo 100nm PSL Thermo 200nm PSL N/A N/A N/A 1.058425 -1.05886 0.999217 1.03149 -0.59679 0.998093 0.976263 0.256106 0.993112 1 Sample concentrations less than 3 times blank levels 2 One-point calibration N/A N/A N/A 1.036725 -0.66789 0.995408 0.954687 0.344229 0.997201 0.9762 0.246149 0.99437 N/A N/A 0.988068 -0.0836 0.998873 0.937519 0.578541 0.995585 0.973449 0.288806 0.993616 Electrospray and Nanometer Aerosol Sampler Operation The TSI model 3480 Electrospray Aerosol Generator (EAG) was used in combination with the TSI 3089 Nanometer Aerosol Sampler (NAS) to deposit nanoparticle reference standards onto 3 mm grids for analysis by transmission electron microscopy (TEM). This method is used to verify nanoparticle size and concentration measurements obtained from the LNS instrumentation. 100nm PSL reference standards were diluted to a known concentration, and the solution was pushed through a 40 m capillary to the EAG while applying a voltage of 2.16 kV to a platinum electrode immersed in the solution and exerting an electric field (391 nA) at the capillary tip. The resulting aerosol was sent to an EC fitted with a DMA operated at a voltage of -2,444 V to select 100 nm particles. After the DMA the flow was split; 0.3 LPM was sent to a TSI 3776 CPC, and the remaining 1.2 Lpm was sent to the NAS (operated with nominally 10,000 V applied to the collection surface to attract the aerosol particles to the strategically positioned TEM sample grid).