Internal Combustion Engine

advertisement

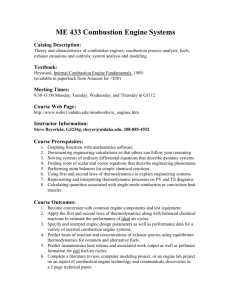

Page |1 A Brief Look into the Variations of Internal Combustion Engines and the Physics That Make Them Run Brandi Pace, Jared Wiggins & John Sandberg Physics 1010; Professor McDonald; Salt Lake Community College April 5th, 2011 Page |2 The engine has led us on a rollercoaster of adaptation and change that’s helped us improve. It is important to look at when the engine was created, how it’s changed, and what benefits it’s provided. From the early 1800’s the internal combustion engine advanced from a gun powder fueled design, into a gas-powered four speed engine just before the turn of the century. Similar to a gun firing a bullet, the basis of how an engine works is compression and expansion. Large amounts of energy come from burning fuel in a confined space which is converted into work and used to make power. Two-stroke and four-stroke engines must alter liquid into vapor to produce power using a carburetor. The combustion cycle is made up of four steps; intake, compression, combustion and exhaust. Intake occurs when the piston is lowered, creating a vacuum, and valves open allowing air and fuel into the combustion chamber. Compression is next as the piston is pushed up in the chamber compressing the mixture. As the piston reaches the top of the chamber a spark ignites the mixture making an explosion which forces the piston down, creating power. Exhaust is the final step which is the release of the burnt chemicals and gasses. However, exhausts being released in large amounts can cause health irritations and respiratory issues. A device called the Positive Crankcase Ventilation redirects the unburned vapors back into the engine to be burned, causing less to be emitted into the air. Since its creations, the benefits of the engine are countless and the ability to transport large quantities of product across the world has changed everything. With this invention, business men are able to hurry to meetings across town, farmers are able to collect crops in large quantities, and we are able to send packages to our families across the states. No doubt the internal combustion engine is a priceless invention and indispensable additive to our daily lives. Page |3 Engines play a vital role in today’s society and, for most, are as much a part of daily life as food and water. An engine, by definition, is a machine that converts any of various forms of energy into mechanical force and motion. Specifically, an internal combustion engine is any engine which uses combustion of fuel to push a piston in a cylinder, and that piston’s movement turns a crankshaft that then turns a chain or drive shaft (putting things like cars in motion). (about.com) Internal combustion engines, or at least the thought of them, have been around since the 1600’s. Christian Huygens designed a combustion engine (1680) and although he never built it, it was designed to run on gunpowder. Francois Isaac De Rivaz (1807) furthered Huygens thoughts and tried using hydrogen and oxygen as fuel, and although it was never functional, he is known for making the first automobile using an engine. The idea of using gasoline for power came in 1824 by Samuel Brown, which led to the design of a double-acting, electric-spark internal ignition combustion engine that was powered by coal gas from Jean JospephEtinee Lenoir (1858). Lenoir was also the first to attach Figure 1.1: Lenoir’s historical cart that survived fifty miles being pulled by his combustion engine. his combustion engine to a cart (see figure 1.1), which managed to complete a fifty mile road trip! (inventors.about.com) Just a few years later Alphonse Beau de Rochas designed and patented the first known four-stroke engine and in 1864 Siegfried Marcus put those designs into action by making the first gasoline powered vehicle. He’s known as the forerunner of the modern automobile because he was first to build a single cylinder engine with a crude carburetor and attached it to a cart which went 500 feet (see figure 1.2), thereafter he went on to build a model which is most famous for Page |4 being the first car design (inventors.about.com). From this point in time there was a working engine that others could modify and adapt, making their own versions. Nicholas August Otto is still known today for his expansions on the engine. In 1876 he invented an efficient gas engine and effectively built the first four-stroke engine (which later became a motorcycle), this design is known as an “Otto Cycle Engine” Figure 1.2: The first ‘Marcus’s car’ which earned fame for being the first car design. (imperialclub.com). Karl Benz then used the idea to build the world’s first automobile powered and fueled by the internal combustion engine (1885). Benz received the first patent for a gas-fueled car and, by 1900, was the largest manufacturer of automobiles. The engines new small size, gasoline-injected carburetor and vertical cylinder made way for a revolutionary design when Gottlieb Daimler and Deutz Gasmotorenfabrik built their first automobile with a four-speed transmission that reached a speed of up to 10 miles per hour. The designs soon made their way to America where Ransom Olds was the first to mass produce his construction of the automobile in 1901. Henry Leland and Henry Ford were not far behind. (imperialclub.com) Every one of these individuals furthered the process of providing the internal combustion engine, as well as the latest model of the automobile, which has been the primary use of transportation for the world since its creation and construction. With many changes being made since its creation, it has evolved into the engine we know well today and continues to be the most effective way of transport. When it comes to the ‘how’ of an engine, there is a lot going on. Using physics, we can explain what makes the baffling chunk of metal under our car hoods start and take us where we Page |5 want to go just by turning a key. An internal combustion engine works mostly on the principles of compression and expansion, similar to a bullet being fired from a gun. The expansion of compressed, exploding gasses force stationary parts into motion. The internal combustion engine essentially uses heat to operate, the fuel is burned within a confined space and the burning process releases large amounts of energy which are converted into work through the rest of the engine. However, unlike a bullet being fired, this energy is harnessed productively and consistently to produce massive quantities of power used for many purposes that keep the wheels of our society moving. When speaking of gasoline powered engines in a general sense, there are two main types; two-stroke and four-stroke. A four-stroke engine is mostly found in automobiles, but has easily worked their way into motorcycles, boats and snowmobiles. Whereas a two-stroke engine is found mostly in household power equipment such as lawnmowers, tillers, snow blowers, etc. as well as motorcycles, four-wheelers, and other off highway vehicles. These, by far, are not the only type of engines; however, when talking about internal combustion they are the most common. In order for liquid fuels to be utilized, the engine must alter the liquid into a vapor. This process started with what was called the “hot bulb engine” in 1885. The hot bulb engine sprayed the gasoline onto an extremely hot surface next to a cylinder, and then took the evaporation into the engine from there (bookrags.com). As we progressed more the carburetor was developed, which mixes air with the liquid fuel and in turn changes it into the vapor state. A flame (or spark) inside the engine causes the mixture to explode (forcing movement in the engine). While you can still find carbureted engines today, fuel injection is much more common. A fuel injector is an electromagnetic device that stores fuel in a small chamber and when the injector is Page |6 activated, “the magnet lifts up and moves a needle with it to expose a small set of orifices at the bottom through which fuel is dispensed as a spray.” The injector has power running to it at all times (as long as the key is on) and nowadays the computers in our car handle the timing and process of most things. This brings us back to the four-stroke and the two-stroke engines. The term four-stroke, based on the Otto Cycle Engine (after Nicholas August Otto mentioned above), refers to the four distinct motions that the piston goes through during a conversion of the chemical energy into rotational energy harnessed. The four different strokes for each combustion cycle are: 1. Intake: an intake valve opens and allows for an air/fuel mixture to enter the combustion chamber. As the piston lowers it creates a vacuum, generating the suction that brings in the air and fuel. 2. Compression: the piston is pushed upwards by the momentum of the flywheel and crankshaft compressing the air/fuel mixture. 3. Combustion: as the piston reaches the top of its stroke, the air/fuel mixture is ignited by the spark plug. Due to the compression in the mixture (typically 190 psi in most engines) it explodes when a spark is introduced, then the expanding gasses push the piston downwards and create power. 4. Exhaust: after the air/fuel mixture has been burnt the remaining chemicals and gasses in the cylinder (mostly water and CO2) must be expelled to allow for fresh air/fuel to fill the cylinder for another rotation. As the piston rises to evacuate the cylinder an exhaust valve opens and allows the spent fuel to leave the cylinder. Each stroke can be seen and visually defined below in figure 1.3 (visual.merriam-webster.com). Page |7 Figure 1.3: Beginning at the top left and moving clockwise, we see each stroke in the combustion cycle (Intake, compression, combustion and exhaust). The timing of all four-strokes is crucial to the engine running. This is why there are other components to the engine, like the timing belt that controls the timing of the piston in relation to the valves. If the timing is off, engine damage could occur. A two-stroke engine works very much in a similar manner. As the piston lowers, there are passages in the cylinder walls that allow the air/fuel mixture into the combustion chamber. The piston rises and compresses the gasses and, when compressed, the air/fuel mixture is ignited. The expanding gasses push the piston downward and create power. As the piston falls to its lowest point in the cylinder, the spent fuel is expelled and a fresh mixture is introduced (see figure 1.4 from the Figure 1.4: A look inside a two-stroke engine and its combustion cycle. Encyclopedia Britannica Online). The significant differences from four-stroke engines are; twostroke engines don’t have valves, which give it a simpler design advantage and lower its weight, and a two-stroke fires once every revolution giving them a significant power boost. These advantages contribute to weight, as mentioned already, and make it cheaper to manufacture. As Page |8 with anything, however, there are disadvantages as well. First, the lack of a lubricating system (oil) contributes to a much shorter life cycle because it puts more wear on the engine parts. Second, the oil you do use is much more expensive than that of a four-stroke engine. A twostroke engine requires a mix of fuel and oil to lubricate the system. Because the fuel is mixed with the oil, you would need about four ounces of oil per gallon of gas (howstuffworks.com). A third method invented by Rudolf Diesel is the diesel compression engine. Instead of having an additional heat source (now known as spark plugs) to ignite the gas, as in the previously mentioned methods, Diesel came up with a process in that the gas ignited itself. Today, diesel engines are most commonly found in large commercial vehicles, many American trucks, and European cars. The most significant difference of a Diesel engine is the fuel. Although both diesel and gasoline are derived from the same crude oil, they are extracted at different temperatures during the refining process. Diesel fuel is actually more efficient than its counterpart because the density is higher, allowing for more energy from each combustion cycle to be harnessed. A diesel internal combustion cycle differs from the gasoline four-stroke engine by using only compression to ignite the fuel rather than introducing a spark (compression ignition rather than spark ignition). In a diesel engine, air is compressed in the piston raising the temperature (as you compress air it warms) from there the fuel is directly injected into the combustion chamber. As soon as the fuel is introduced to the air it combusts, forcing the piston downward. However, because of the rapid pressure jumps that occur when each piston is fired, a diesel engine works noisily and with excessive vibration. This requires a diesel engine to be much more durable than a gasoline engine, increasing its weight. That being said, the most noticeable advantages to Page |9 owning a diesel are; the fuel efficiency, there is less of a fire hazard, lower emission levels, and the power obtained by the engine. The basic disadvantages are that it’s expensive, both in manufacturing (due to its high work load) and in the cost of diesel fuel, as well as the maintenance. There are also some problems with diesel fuel freezing, making it so you either have to heat the fuel lines and tank or get ‘winter diesel fuel’ which has an additive to lower the temperature in which it freezes; however, gasoline cannot freeze so it’s not a concern. While the gasoline and diesel engines were being developed around the same time, there are a few reasons the gasoline engine quickly came out on top; its wide revolutions per minute (rpm) range, ease of starting, smooth and quiet operation, and its good acceleration. Not long after the engine was invented, and in fact well before the automobile existed, the advent of forced induction began to change everything. “Conceived in 1885, driven at 100 mph in 1908, diversifying through the 20s and 30s, consolidating in the War, resurging in the 60s, and creating efficiencies in the 80s”, many have been hooked to benefits of forced induction since (coloradocobras.com). Forced induction is where a compressor system is attached to the intake side of an internal combustion engine to increase the pressure, temperature and density of the air. An engine without a compressor is considered to be a ‘naturally aspirated engine. As previously mentioned, the energy (or power) that comes from an engine is produced by the downward force of the piston as the fuel/air mixture explodes. In order to make more power you must have a more powerful downward force on the piston, which can be done by adding more air and fuel into the cylinder during each cycle. This can be done with forced induction, where air and/or fuel are ‘force fed’ into the combustion chamber. P a g e | 10 There are two common types of compressors used today, turbochargers and superchargers. A turbocharger is a centrifugal compressor which relies on the volume and velocity of the engines exhaust to spin a turbine that is connected to the compressor with a common shaft (see figure 1.5 from turborx7.com). The air pressure is regulated by a system of valves and electric controllers. The greatest benefit of a turbocharger, Figure 1.5: A simple diagram of a turbo system in comparison to a supercharger, is that the turbocharger draws less power from the engine than a supercharger will. Of course, the turbo has drawbacks as well; being that the turbine is driven from the engines exhaust, the response of the engine suffers which is referred to as ‘turbo lag’. The use of a turbocharger is always a compromise. For example, if you use a smaller turbine to increase your boost pressure and response at lower rpms, you suffer in the higher rpm range; whereas, a larger turbo will suffer on the low end of the rpms. On the other hand, superchargers have very little lag time to build pressure, because the compressor is always running at a speed proportional to the engine itself. A basic supercharger uses paddles on two rotation drums attached to the engine drive, usually by belt, to force air into the intake system. The most prominent advantage of a supercharger is that it is attached to the engines drive and is able to produce the same compression at any speed, giving you nearly instant power. The downfall of a supercharger is the fact that it is attached to the engines drive and uses the torque of the engine itself to compress air (it takes power to make power); this results in a loss of efficiency and power. The first law of thermal dynamics states that as a gas is compressed it becomes hotter; P a g e | 11 this presents a problem for forced induction engines. Starting with the emissions, higher compression leads to higher combustion temperatures, this in turn leads to a higher output of NOX. This is the amount of nitrogen-oxygen compounds emitted into the atmosphere, in which the levels of such are government regulated (we’ll talk more about this later). Another problem created when the higher temperatures are formed is that the fuel can ignite before a spark is introduced. When this happens it’s called pre-ignition, detonation, or knock; these can be dangerous and can cause significant engine damage. To compensate for these side effects most forced induction engines incorporate the use of an intercooling system. This allows ambient flow of air to pass the air leaving the turbo/supercharger, increasing the charged airs density and cooling the entire system. These downfalls of forced induction typically only affect four-stroke gasoline engines, rather than diesel engines. This is because there is no chance for a pre-ignition detonation with a diesel engine, due the fact that there is no spark introduced as it relies completely on high compression to raise the fuel/air mixture to the igniting point. Between the two options, a turbocharger is usually the one found on a diesel engine, simply because the higher compression in the pistons makes the exhaust output exceptionally strong (making it perfect for powering a turbo). We’ve briefly mentioned emissions up to this point. With the mass production of the automobile to the public all around the world, many organizations took to joining the “band wagon” in designing their own body types, engine placements, and adaptations. With the increasing desire for the new automobile, unforeseen problems arose. From 1906 to 1950 there was little attention paid to lasting negative effects that might emerge from the new found world P a g e | 12 experiment. There are several emissions that are produced in the combustion process, including: Nitrogen (N2), Carbon Dioxide (CO2), Water (H2O), Oxygen (O2), Sulfur Dioxide (SO2), Hydrocarbons (HC), Oxides of Nitrogen (NOX), and Carbon Monoxide (CO). However, from 1950 to 1960, various federal, state, and local governments conducted experiments on the increasing air pollution and how it was affecting their communities. While all of the emissions mentioned above aren’t necessarily harmful to the environment, the studies concluded that a majority of the pollution problems that were arising were due to the new automobile. In 1961 the implementation of a new part to the internal combustion engines was the first designed and constructed into the automobile. It was called the Positive Crankcase Ventilation or PCV. This device drew in the unburned thick Hydrocarbons into the engine’s intake tract so that they could be burned inside the engine instead of released directly into the atmosphere. If not burned inside the engine, the Hydrocarbons would be released and form smog, or photochemical smog, which is hazardous to living organisms. In 1965, a new car would have produced about one ton (2,000 lbs.) of smog forming Hydrocarbons during 100,000 miles of driving. PCV quickly became required equipment in all new vehicles in the 1960’s (VW selfstudy program). Quickly following the PCV equipment, the tailpipe was introduced to better the quality of vehicles and their emissions. 1966 was the first year that the state of California required all vehicles to be equipped with a tailpipe (jdpower.com). The tailpipe did not necessarily better the air quality but it directed the exhaust gases from the engine. After this exhaust tubing was added onto vehicles, the additional catalytic converter was added. The Catalytic Converter was used to reduce the array of emissions from internal combustion engines. It functions by using a catalyst (a wire mesh or honeycomb, which allows a high surface area to be exposed to the passing P a g e | 13 exhaust gasses) to create a chemical reaction through which by-products from combustion are converted to produce less harmful substances. A prime example of this would be the very toxic gas carbon monoxide converted to carbon dioxide. The use of this device caused an astonishing 90% of all toxic gasses, such as hydrocarbons and carbon monoxide from internal combustion engines, to be converted to less harmful gasses. Similar to the invention of the catalytic converter, and the tailpipe or exhaust tubing, many other devices were created including; air intake, exhaust gas recirculation, electronic ignition, and computerized engine management. Many adaptations to original models and designs of emission systems have been put into effect and in the last 13 years, we have gone from producing 50 lbs. of smog forming hydrocarbons to a single pound in Super Ultra Low Emission Vehicles during 100,000 miles of driving. These new vehicles such as the Lexus RX 400h, Mazda Tribute hybrid, and Toyota Highlander hybrid, have been given the title of “Smartway Elite” designation. They have very low emissions without a compromise of power (jdpower.com). With the demands society has for cleaner burning and more plentiful fuels, alternate energy engines are more copious and being developed more than ever before. Propane and natural gas engines are available today in automobiles and are gaining popularity. Along with the production line engines, conversion kits are also readily available that allows most vehicles to be run on these alternate fuels. A natural gas engine works on nearly the same principles as the four-stroke gasoline engines. In these engines, the liquid fuel in the tanks is converted to a vapor to allow it to run into the fuel lines. The vapor is then passed through a mixer that combines the fuel with air, and from that point the combustion process is the same (the fuel/air mixture is P a g e | 14 vented into the combustion chamber, compressed, and ignited). Because the fuel is introduced as a gas, instead of liquid, it burns cleaner leaving virtually no residue (increasing the time between oil changes from the average 3,000 to 5,000 miles to nearly 10,000 miles) (Hofmann). Additionally; whether you believe in global warming, the shortage of our oil supply, or just ‘going green’, one thing is certain: prices of gasoline is continually rising, leaving more of a demand for improving fuel economy and cleaner emissions. Despite this hype, it seems that internal combustion engines aren’t going anywhere in the foreseeable future. Electric cars are being experimented with; however, the primary downfall to an electric engine is cost. According to Ccaga Csere of Car and Driver; “the battery alone in an electric car can cost $20,000, and will remain so for some time” (caranddriving.com). Furthermore, there are adaptations to the internal combustion engine and we’ve already mentioned a few (natural gas or propane). There are also things like direct injection, variable displacement, homogenous-charge compression ignition, and new stop-start systems on the horizon. We’ll start with direct injection; when you inject fuel directly into the combustion chamber during the compression stroke, the cooling process of the vaporizing fuel doesn’t completely disappear before the spark plugs ignite. This means the engine is more resistant to premature detonations and can operate with a higher compression ratio. “This alone improves fuel economy by two to three percent”, according to Csere; in addition, this offers the possibility of a leaner running engine “that could yield giver percent more efficiency” (caranddriver.com). Next is variable displacement, meaning that the engine could turn off some of its cylinders to improve efficiency. This feature is already on the market today, although it hasn’t caught on yet because of its higher costs. In addition, there is homogenous-charge compression ignition. This is essentially a combination of the gas engine and a diesel. It can operate both like a typical P a g e | 15 gasoline engine, with combustion initiated by a spark plug, and can operate like a diesel, where the combustion is caused by the heat of the compression. It may be complicated for manufactures, but “the payoff can be a 20-percent improvement in fuel economy”, says Csere. Lastly, turning an engine off when the car is stopped (stop-start systems) can be a definite gain when it comes to saving fuel. There have been engines in the making that have computer programs to do just that; however, as with any change, manufacturers seem to be reluctant to invest without sufficient testing. With that, the internal combustion engine has been a significant part of society all around the world for the past one hundred years. We’ve battled any unforeseen problems in the past and will continue to do so as long as we crave the benefits of fast and easy transportation. While the fundamental way an internal combustion engine works hasn’t much changed, there have been improvements, modifications, and emissions have been redesigned and converted to adapt our ever growing needs. Four-stroke, two-stroke, diesel, turbo, electric, and so on have had many changes that are both unique and specific. All these new adaptations push us forward with little to no glances back into the past; however, if it weren’t for these adaptations in life we wouldn’t be as progressed and advanced as we are today. P a g e | 16 Bellis, Mary. "The History of the Automobile, The Internal Combustion Engine and Early Gas-Powered Cars." 2011: n. pag. Web. 4 Apr 2011. <http://inventors.about.com/library/weekly/aacarsgasa.htm>. "History of the Internal-Combustion Engine." Imberial Web Pages 28 Apr 2001: n. pag. Web. 4 Apr 2011. <http://www.imperialclub.com/Repair/Engine/history.htm>. Dinan , Steve . "The Future of the Internal Combustion Engine." 09 Mar 2008: n. pag. Web. 4 Apr 2011. <http://www.bimmerfest.com/forums/showthread.php?t=268840>. CSERE, CSABA. "The Future of the Internal -Combustion Engine - Near-Term and Long-Term Innovations." Apr 2010: n. pag. Web. 4 Apr 2011. <http://www.caranddriver.com/features/10q2/the_future_of_the_internal combustion_engine-feature>. Zandonella, Catherine. "UC Berkeley researchers create world's smallest rotary internal combustion engine ." Media Relations 02 Apr 2001: n. pag. Web. 4 Apr 2011. <http://berkeley.edu/news/media/releases/2001/04/02_engin.html>. "four-stroke-cycle engine." Visual Dictionary Online. Web. 4 Apr 2011. <http://visual.merriam-webster.com/transport -machinery/road -transport/typesengines/four-stroke-cycle-engine.php>. Brain, Marshall. "How Two -stroke Engines Work." n. pag. Web. 4 Apr 2011. <http://science.howstuffworks.com/transport/engines -equipment/two stroke.htm>. "Understanding Low-Emission Vehicles." J.D. Power and Associates 2011: n. pag. Web. 5 Apr 2011. <http://www.jdpower.com/autos/articles/understanding -lowemission-vehicle/>. Hofmann, Franz. "Alternate Fuels." 16 Jan 1995. : n. pag. Web. 5 Apr 2011. <http://franzh.home.texas.net/lean.html>. "The History Of Supercharging And Turbocharging." n. pag. Web. 6 Apr 2011. <http://coloradocobras.com/whipple/superchargers/history supercharging.html>.