5726

advertisement

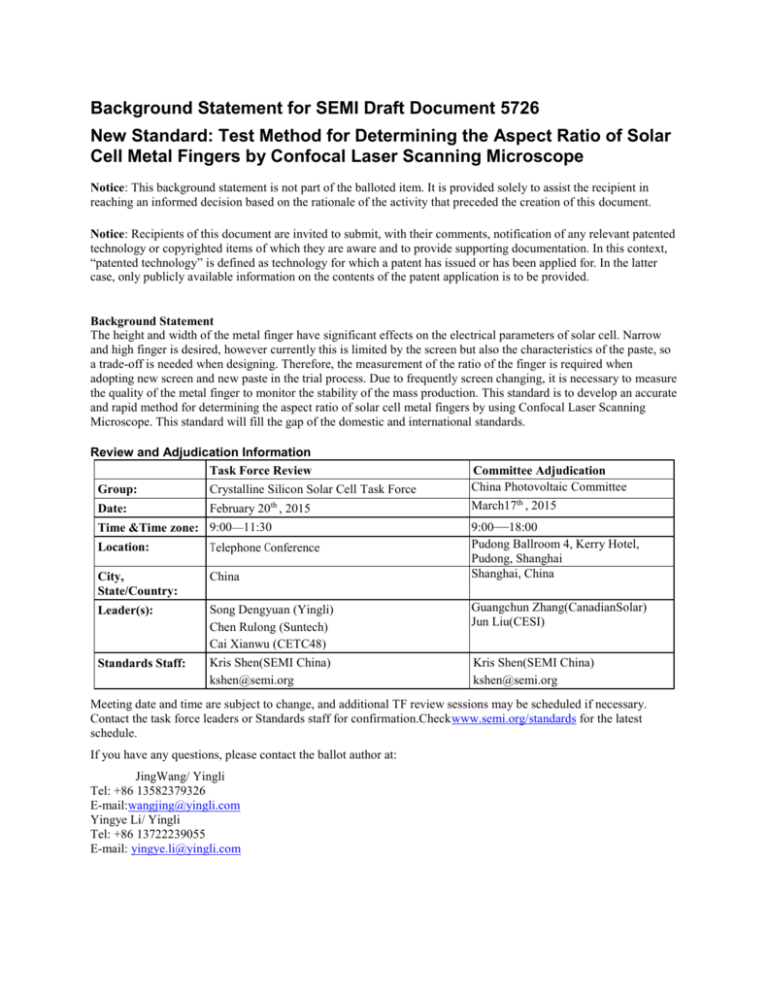

Background Statement for SEMI Draft Document 5726 New Standard: Test Method for Determining the Aspect Ratio of Solar Cell Metal Fingers by Confocal Laser Scanning Microscope Notice: This background statement is not part of the balloted item. It is provided solely to assist the recipient in reaching an informed decision based on the rationale of the activity that preceded the creation of this document. Notice: Recipients of this document are invited to submit, with their comments, notification of any relevant patented technology or copyrighted items of which they are aware and to provide supporting documentation. In this context, “patented technology” is defined as technology for which a patent has issued or has been applied for. In the latter case, only publicly available information on the contents of the patent application is to be provided. Background Statement The height and width of the metal finger have significant effects on the electrical parameters of solar cell. Narrow and high finger is desired, however currently this is limited by the screen but also the characteristics of the paste, so a trade-off is needed when designing. Therefore, the measurement of the ratio of the finger is required when adopting new screen and new paste in the trial process. Due to frequently screen changing, it is necessary to measure the quality of the metal finger to monitor the stability of the mass production. This standard is to develop an accurate and rapid method for determining the aspect ratio of solar cell metal fingers by using Confocal Laser Scanning Microscope. This standard will fill the gap of the domestic and international standards. Review and Adjudication Information Task Force Review Group: Crystalline Silicon Solar Cell Task Force Committee Adjudication China Photovoltaic Committee Date: February 20th , 2015 March17th , 2015 Time &Time zone: 9:00—11:30 9:00—18:00 Pudong Ballroom 4, Kerry Hotel, Pudong, Shanghai Shanghai, China Location: Telephone Conference City, State/Country: China Leader(s): Song Dengyuan (Yingli) Chen Rulong (Suntech) Cai Xianwu (CETC48) Guangchun Zhang(CanadianSolar) Jun Liu(CESI) Standards Staff: Kris Shen(SEMI China) kshen@semi.org Kris Shen(SEMI China) kshen@semi.org Meeting date and time are subject to change, and additional TF review sessions may be scheduled if necessary. Contact the task force leaders or Standards staff for confirmation.Checkwww.semi.org/standards for the latest schedule. If you have any questions, please contact the ballot author at: JingWang/ Yingli Tel: +86 13582379326 E-mail:wangjing@yingli.com Yingye Li/ Yingli Tel: +86 13722239055 E-mail: yingye.li@yingli.com Semiconductor Equipment and Materials International 3081 Zanker Road San Jose, CA95134-2127 Phone:408.943.6900, Fax: 408.943.7943 DRAFT SEMI Draft Document 5726 New Standard: Test Method for Determining the Aspect Ratio of Solar Cell Metal Fingers by Confocal Laser Scanning Microscope 1 Purpose 1.1 The purpose of this standard is to standardize a fast and accurate test method for determining the aspect ratio of solar cell metal fingers by Confocal Laser Scanning Microscope(CLSM). 2 Scope 2.1 This standard defines the test method for determining the aspect ratio of solar cell metal finger. 2.2 This standard applies to test the aspect ratio of solar cell metal finger by Confocal Laser Scanning Microscope. NOTICE: SEMI Standards and Safety Guidelines do not purport to address all safety issues associated with their use. It is the responsibility of the users of the documents to establish appropriate safety and health practices, and determine the applicability of regulatory or other limitations prior to use. 3 Referenced Standards and Documents 3.1 ISO Standard1 ISO 14644-1—1999 — Cleanrooms and Associated Controlled Environments —Part 1: Classification of Air Cleanliness NOTICE: Unless otherwise indicated, all documents cited shall be the latest published versions. 4 Terminology 4.1 Abbreviations and Acronyms 4.1.1 CLSM—Confocal Laser Scanning Microscope 4.1.2 G—gram 4.1.3 ℃—degrees Celsius 5 Summary of Test Method 5.1 Confocal Laser Scanning Microscopy uses a laser as light source and is configured on the traditional optical microscope using conjugate focus device. The system uses a computer digital image processing to observe and analyze the object of interest. Principle of CLSM is shown in figure 1. 5.2 The fundamental principle of the Confocal Laser Scanning Microscopy: a specific wavelength light excited by the laser is magnified and passed a lighting pinhole diaphragm in the scanner.Then a dot photosource is formed and focused on the plane by the objective, a fluorescence which is emitted on the irradiated dot on the sample pass the detected diaphragm and reach the detector, and finally imaging in the computer. 1 International Organization for Standardization, ISO Central Secretariat, 1 rue de Varembé, Case postale 56, CH-1211 Geneva 20, Switzerland; Telephone: 41.22.749.01.11, Fax: 41.22.733.34.30, http://www.iso.ch This is a Draft Document of the SEMI International Standards program. No material on this page is to be construed as an official or adopted Standard or Safety Guideline. Permission is granted to reproduce and/or distribute this document, in whole or in part, only within the scope of SEMI International Standards committee (document development) activity. All other reproduction and/or distribution without the prior written consent of SEMI is prohibited. Page 1 Doc. 5726 SEMI LETTER (YELLOW) BALLOT Document Number: 5726 Date: 2/10/2016 Semiconductor Equipment and Materials International 3081 Zanker Road San Jose, CA95134-2127 Phone:408.943.6900, Fax: 408.943.7943 DRAFT LETTER (YELLOW) BALLOT Document Number: 5726 Date: 2/10/2016 Figure 1 Principle Diagram of CLSM 6 Apparatus 6.1 Confocal Laser Scanning Microscope 6.2 Computer 6.3 Electronic Balance —Tolerance ± 0.002g 7 Safety Precautions 7.1 Power switch and the power outlet of the CLSM are checked in security before and after use. 8 Test Specimens 8.1 Weigh cells with electronic balance before and after printing, and make sure the weight of the paste is within the control range. 8.2 Randomly take three cells with the full pattern and no printing interrupt and defect. 9 Preparation of Apparatus 9.1 Because of the high sensitivity of the crystalline silicon wafer surface, the testing environment should meet the following requirements: 9.1.1 Ambient temperature should be 25℃±2℃, ambient humidity should be 60%±20%. This is a Draft Document of the SEMI International Standards program. No material on this page is to be construed as an official or adopted Standard or Safety Guideline. Permission is granted to reproduce and/or distribute this document, in whole or in part, only within the scope of SEMI International Standards committee (document development) activity. All other reproduction and/or distribution without the prior written consent of SEMI is prohibited. Page 2 Doc. 5726 SEMI Semiconductor Equipment and Materials International 3081 Zanker Road San Jose, CA95134-2127 Phone:408.943.6900, Fax: 408.943.7943 DRAFT 9.1.2 Environmental cleanliness should be better than 6 grade clean room requirements as defined in ISO 14644-11999 “Cleanrooms and associated controlled environments—Part 1:Classification of air cleanliness”. 10 Calibration and Standardization 10.1 Install and level the CLSM. 10.2 Floor vibration is 1.5 m/s2 or less (For frequencies less than 5 Hz, the amplitude should be less than 3µm). 10.3 Authority metering mechanism calibrated electronic balance every year. 10.4 Zero the balance before using the electronic balance. 11 Procedure 11.1 Select the 50X objective lens. 11.2 Place the sample on the stage, adjust sample position and focus on finger. 11.3 Adjust the. stage to focus to the top position of the fingers and then wafer surface, record the position information. 11.4 Select the test points(Except for explicit demand by customer). 11.4.1 Select the test starting point, start measuring minimum starting point of fingers with testing from silicon and paste contact. 11.4.2 Select five parts for the finger test, 280 µm length per section, in the case of "skip=10", select the average height and width of 100 cross selection on the selected part.(See Figure 2.) Figure 2 Schematic diagram of fingers test point 11.5 Test each points on the samples according to the test requirements. 11.6 Finish test and record, fix the peak position and width in accordance with the 3D graph, then record the display width and height values. 11.7 Calculate the average height and width, and aspect ratio of fingers accordingly. 12 Calculations 12.1 The average height of fingers: (1) This is a Draft Document of the SEMI International Standards program. No material on this page is to be construed as an official or adopted Standard or Safety Guideline. Permission is granted to reproduce and/or distribute this document, in whole or in part, only within the scope of SEMI International Standards committee (document development) activity. All other reproduction and/or distribution without the prior written consent of SEMI is prohibited. Page 3 Doc. 5726 SEMI LETTER (YELLOW) BALLOT Document Number: 5726 Date: 2/10/2016 Semiconductor Equipment and Materials International 3081 Zanker Road San Jose, CA95134-2127 Phone:408.943.6900, Fax: 408.943.7943 DRAFT Where: —average height of fingers, µm; —the height of n-th finger of selected test point, µm. 12.2 The average width of fingers (2) Where: —average width of fingers, µm; —the width of n-th finger of selected test point, µm. 12.3 Finally according to formula (3) can calculate the respect ratio of fingers (3) Where: r —the respect ratio of fingers; —average height of fingers, µm; —average width of fingers, µm. 13 Report 13.1 The report shall contain the following elements; 13.1.1 Sample sources, sample names; 13.1.2 Characterization and condition of the test item; 13.1.3 Date of receipt of test item and date of test, where appropriate; 13.1.4 Test result(contain the test cure and the calculation results); 13.1.5 Tester, review, approval, report number; 13.1.6 Testing agencies, testing name, testing address. NOTICE: Semiconductor Equipment and Materials International (SEMI) makes no warranties or representations as to the suitability of the Standards and Safety Guidelines set forth herein for any particular application. The determination of the suitability of the Standard or Safety Guideline is solely the responsibility of the user. Users are cautioned to refer to manufacturer’s instructions, product labels, product data sheets, and other relevant literature, respecting any materials or equipment mentioned herein. Standards and Safety Guidelines are subject to change without notice. By publication of this Standard or Safety Guideline, SEMI takes no position respecting the validity of any patent rights or copyrights asserted in connection with any items mentioned in this Standard or Safety Guideline. Users of this Standard or Safety Guideline are expressly advised that determination of any such patent rights or copyrights, and the risk of infringement of such rights are entirely their own responsibility. This is a Draft Document of the SEMI International Standards program. No material on this page is to be construed as an official or adopted Standard or Safety Guideline. Permission is granted to reproduce and/or distribute this document, in whole or in part, only within the scope of SEMI International Standards committee (document development) activity. All other reproduction and/or distribution without the prior written consent of SEMI is prohibited. Page 4 Doc. 5726 SEMI LETTER (YELLOW) BALLOT Document Number: 5726 Date: 2/10/2016