Team 4 DD AB 2012 - Colorado Space Grant Consortium

advertisement

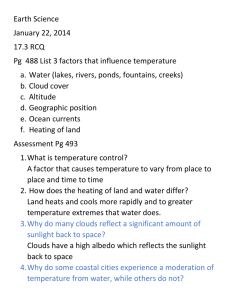

B.O.S.S. – Balloon-Operated Seeding System Colorado Space Grant Consortium GATEWAY TO SPACE FALL 2012 DESIGN DOCUMENT Team Up, Up, and Away Written by: Trevor Arrasmith, Ty Bailey, Cameron Coupe, Samuel Frakes, Brandon Harris, Carolyn Mason, Soo Rin Park, and Peter VanderKley October 22, 2012 Revision A/B Team Up, Up, and Away Page | 1 B.O.S.S. – Balloon-Operated Seeding System Table of Contents 1.0 Mission Overview ............................................................................................................... 3 2.0 Requirements Flow Down.................................................................................................. 4 3.0 Design ................................................................................................................................. 5 4.0 Management....................................................................................................................... 7 5.0 Budget ................................................................................................................................. 9 6.0 Test Plan and Results .......................................................................................................... 10 7.0 Expected Results................................................................................................................. 13 Team Up, Up, and Away Page | 2 B.O.S.S. – Balloon-Operated Seeding System MISSION OVERVIEW: The mission of team Up, Up, and Away is to successfully send a balloon satellite to an altitude of 30,000 meters and test a cloud seeding mechanism at altitudes of 5,000 meters and 15,000 meters. 5,000 meters is the standard altitude of cloud seeding, at which Cumulonimbus and Nimbostratus clouds exist, which are the clouds that commonly produce rain. 15,000 meters is the highest altitude at which clouds exist. [1] Team Up, Up, and Away is attempting to study the feasibility and efficacy of a balloon-mounted cloud seeding system at varying altitudes. Our BalloonSat, named B.O.S.S. (Balloon-Operated Seeding System) will contain a particle substance of finely milled Sodium Chloride, the use of which in cloud seeding is called hygroscopic cloud seeding.[2] The powder will be released at two separate times, one for each of the two cones contained inside the BalloonSat. We will then compare the results of the physical experiment with the data on humidity, temperature, and pressure to prove or disprove the effectiveness of our mechanism. Our mechanism will consist of two funnels, each containing approximately 55 grams of a Sodium Chloride and reflective glitter mixture. A servo below the funnel opening will control the release of the mixture out the bottom of the cube at the determined altitudes. An additional panel of foam core will be placed on the bottom of the cube, partially in the frame of the GoPro, in order to provide a backdrop to better witness the release of the mixture. To our knowledge, no such experiment has been performed, and our findings should be completely original. We hope to be able to achieve data in several different subareas. First and foremost, we hope to prove the feasibility and cost effectiveness of balloon-sourced cloud seeding at standard cloud seeding altitude. The next goal is to find data on the efficacy of our cloud seeding mechanism at standard and high altitude. If this is proven useful, it could have major effect on cloud seeding as a whole. If water vapor exists at higher altitudes at low enough temperatures, only without a particle upon which to condensate, high altitude particle cloud seeding would reveal a previously untapped source of water. Further research in cloud seeding can have long-lasting and global impact. Almost all locations in the world are at one point or another affected by drought or can benefit from additional precipitation. It is cost-efficient as well, as the cost of materials and implementation is fairly cheap even on a large scale, and the resulting precipitation saves a significant amount of money to the area below. The issue strikes particularly close to home here in Colorado, both with the recent drought we have been facing and with the numerous ski resorts in the state dependent on snowfall. If our experiment is proven successful, it may reveal the possibility for even further cloud seeding opportunities in areas which it may not have been previously feasible. Sources Cited: 1. Common Cloud Names, Shapes, and Altitudes. http://nenes.eas.gatech.edu/Cloud/Clouds.pdf 2. Hygroscopic Cloud Seeding. http://www.just-clouds.com/hygroscopic_cloud_seeding.asp Team Up, Up, and Away Page | 3 B.O.S.S. – Balloon-Operated Seeding System REQUIREMENTS FLOW DOWN: The requirements of B.O.S.S. are based upon completing the mission objective of proving the feasibility of balloon-based cloud seeding. In order to accomplish this, we must create a functional and reliable mechanism to release powder at the altitudes where it would be most useful in aiding precipitation from clouds. Furthermore, we must fulfill the requirements of the Request for Proposal- namely the collection of additional science data. Requirement Number Requirement Derived from: Level 0 Requirements Objective 1.0 Objective 2.0 Team Up, Up, and Away will prove the possibility and efficiency of a balloon-mounted mechanism for cloud seeding. Team Up, Up, and Away will test the effectiveness and reliability of the funnel dispersing system of the BalloonSat. Objective 3.0 B.O.S.S. will collect the data of humidity, air pressure, acceleration, wind speed, and inside and outside temperature. Objective 4.0 The integrated GoPro camera in B.O.S.S. will record the flight and also the cloud seeding process. Mission Objective Mission Objective Level 1 Requirements Objective 1.1 Objective 2.1 Objective 2.2 Objective 2.3 Objective 2.4 Objective 3.1 Objective 4.1 Team Up, Up, and Away will prove that given the ability to use enough of the correct substance for cloud seeding, a balloon-mounted mechanism will be feasible and economic. Using the two integrated funnels and servos, the BalloonSat will disperse sodium chloride at two different altitudes. Objective 1.0 The mechanism to release the powder will consist of an oscillating triangular aluminum plate controlled by a Servo, which will block the flow of salt out of the container except when prompted to move. The base plate on which the oscillating plate will rest will also be made out of a 3mm thick aluminum sheet and will assure that the triangular piece can oscillate smoothly against its surface. The funnel will be supported by cross wires so that it does not fall over or get shaken or broken in flight. We will make sure that the salt will not fall out of the cone by securing a lid on the top of it. With the GoPro facing down, it will capture the process of cloud seeding. Using the Arduino and the sensors, the BalloonSat will record the data for temperature, humidity, pressure, and wind speed during the duration of the flight. Objective 2.0 Objective 2.0 Objective 2.0 Objective 2.0 Objective 3.0 Objective 4.0 Team Up, Up, and Away Page | 4 B.O.S.S. – Balloon-Operated Seeding System DESIGN: Because the purpose of our mission is to test the feasibility of balloon-base cloud seeding, we will determine our success based on the functionality of our release system. The BalloonSat will contain two separate but identical release systems, one of which will be programmed to release at an altitude of 5,000 meters and the other of which will be programmed to release at 15,000 meters. To ensure release is successful, there will be a redundancy in the programming that will prompt the servo at a specific time if the determined altitude has not already prompted it. Each system will consist of an aluminum funnel, an aluminum base plate, an oscillating plate, and a servo. The aluminum funnel will contain approximately 55 grams of powder, all of which will release at the predetermined altitude. In order to release, the servo will rotate the oscillating aluminum plate along the top surface of the base plate in order to align the series of holes that will allow powder to flow freely from the funnel and out the bottom of the cube. This system will be mounted to the inner sides of the cube using steel wire, hot glue, and aluminum tape. Two Arduino UNO units will be flown in order to be able to command the servos and collect data from all sensors. The outer structure will consist of foam core, insulation, and a nonmetal flight tube to accommodate the flight string. This design complies with all requirements specified in the Request for Proposal. An anemometer will be included in order to collect additional science data. The mass of the BalloonSat will be at the maximum allowable mass of 1125 grams, but will not exceed it. All required sensors and components such as the Arduino, digital camera, and heater will be flown and the internal temperature will remain above -10 degrees Celsius. The outside of the BalloonSat will have an American flag sticker, contact information, and a CU Buffs sticker in order to assist with its retrieval. In addition, an LED light on the outside of the cube will confirm that all systems are powered on. After flight, the BalloonSat will be analyzed and returned to Professor Koehler in working condition and ready for another flight. The functionality of the mechanisms is dependent on many of the BalloonSat’s parts. The Arduino must command the Servos to oscillate, at which point the oscillating aluminum plate will move along the surface of the base plate and allow the powder to be released. The other Arduino will collect data from the anemometer, temperature sensor, pressure sensor, humidity sensor, and accelerometer, as well as power on the digital camera. The heater will be controlled with an external switch and the GoPro will operate on its own battery power and record data to its own SD card. All parts and hardware have been acquired except for those that can be purchased at local stores such as the reflective glitter and sodium chloride. Ty Bailey has an additional backup servo that we will use in the event of one of our servos failing. We will purchase enough salt and glitter to allow for thorough testing of our mechanism before the flight date. Team Up, Up, and Away Page | 5 B.O.S.S. – Balloon-Operated Seeding System LIST OF PARTS Item Quantity Place of Purchase 9v batteries HS 430BH Servo Tin Funnels Sodium Chloride Glitter Dry Ice Mathmos Wind Light Aluminum Sheet GoPro Canon Camera 9v batteries Switches Heater Foam Core Insulation Steel wire 10 2 2 1 kg 1 bottle (~0.5 kg) 7kg 1 0.5 m2 1 1 3 2 1 1 1 1m Wal-Mart ServoCity.com McMaster.com King Soopers Wal-Mart King Soopers Lamplust.com Provided Donated Provided Provided Provided Provided Provided Provided Provided Status Not yet acquired Not yet acquired Acquired Not yet acquired Not yet acquired Not yet acquired Acquired Acquired Acquired Acquired Acquired Acquired Acquired Acquired Acquired Not yet acquired VISUALIZATION Team Up, Up, and Away Page | 6 B.O.S.S. – Balloon-Operated Seeding System FUNCTIONAL BLOCK DIAGRAM MANAGEMENT: Effective project management is crucial to the success of Team Up, Up, and Away’s mission. Therefore, areas of focus are assigned to each team member, while ensuring that no team member is left alone in any task. A rigid schedule has been constructed to keep the team on track with testing, construction, and other work. Team meetings are held every Saturday at noon. Additional meetings are scheduled as needed, typically on Mondays and Wednesdays. Because the duration of this project spans approximately three months, time limitations are a concern. All team members must budget their time with other classes and will have to devote many hours per week to this project. Team Up, Up, and Away Page | 7 B.O.S.S. – Balloon-Operated Seeding System TEAM MEMBERS AND ROLES: Trevor Arrasmith Ty Bailey Cameron Coupe Samuel Frakes Brandon Harris Carolyn Mason Soo Rin Park Peter VanderKley - Design and Design Illustration-Lead Science and Documentation Videographer Programming-Lead Budgeter Project Manager Electrical Structures-Lead Science and Documentation Science and Documentation-Lead Structure Electrical-Co-Lead Foreman Programming Electrical-Co-Lead Vice Project Manager Programming Structures SCHEDULE Task to be Completed Date Task to be Completed Date First Design Complete PDR Authority to Proceed Hardware Acquired Initial Programming Accelerometer Test CDR Sensor calibration Done Heater Test Camera(s) Test Mass Model Drop Test Whip Test Stair Test Humidity Sensor Test Pressure Sensor Test Temperature Sensors Test Anemometer Test Final structure Powder Release Test 9/27 10/1 10/5 10/10 10/10 10/16 10/18 10/18 10/18 10/20 10/21 10/21 10/21 10/21 10/27 10/27 10/28 10/28 10/29 10/29 Electronics Build BalloonSat Completed Complete Programming Cooler Test Complete Systems Test Demo Mission Test Launch Readiness Review DD Rev C Due Final Weigh-in Launch Troubleshooting Analysis of Flight Data ITLL Design Expo Document Results Final Report Team Video Assembly Final Presentation Due 10/31 10/31 11/2 11/ 11/4 11/13 11/27 11/15 11/30 12/1 11/5 - 12/9 12/1 – 12/7 12/8 12/9 12/9 11/1 – 12/10 12/11 Team Up, Up, and Away Page | 8 B.O.S.S. – Balloon-Operated Seeding System BUDGET: Item 9V batteries Mighty Mini Servo (HS-225MG) Aluminum Bare Sheet Tin Funnels (8996T12) Sodium Chloride Powder Mathmos Wind Light (Part # not available) GoPro Canon Camera Arduino Unos (2) Heater Foam Core and Insulation U.S. Flag Hot Glue Aluminum Tape Steel Wire Quantity 5 2 Cost $42.97 Weight 190 g 62 g Place of Purchase Wal-Mart Servocity.com 0.5 meters2 2 $8.62 20 g 61.9 g Space Grant Mcmaster.com 110 grams 1 $25.20 110 g 11.5 g King Soopers Lamplust.com 1 1 2 1 2 sheets 1 2 sticks 5 meters 1 meter - 150 g 130 g 158 g 30.4 g 185 g ~0g 6g 6g 5g Provided (by student) Provided Provided Provided Provided Provided Provided Provided $76.79 1,124.8 g Total Company contact information: Servocity McMaster Lamplust Phone: (620) 221-0123 Phone: (630) 833-0300 Email: chi.sales@mcmaster.com Address: 600 N County Line Rd. Elmhurst, IL 60126-2081 Phone: (866) 490-9358 Email: sales@lamplust.com BUDGET MANAGEMENT: Ty Bailey Ty Bailey is the budget manager. He will keep an itemized list of all the parts, their place of purchase, cost of part and shipping. He will verify these costs with professor Koehler. Team Up, Up, and Away Page | 9 B.O.S.S. – Balloon-Operated Seeding System TEST PLAN AND RESULTS: TESTING SCHEDULE: Structures Testing: • Powder Release test (10/29) • Drop Test (10/21) • Whip Test (10/21) • Stair Test (10/21) Electronics Testing: • Accelerometer (10/16) • Heater (10/18) • Camera(s) (10/20) • Humidity Sensor (10/27) • Pressure Sensor (10/27) • Temperature Sensors (10/28) • Anemometer (10/28) Systems Testing: • Cooler Test (11/3) • Complete Systems Test (11/4) • Demo Mission Test (11/13) STRUCTURAL TESTING: DROP TEST: Once the structure is completed, we will test its integrity by dropping it from several stories. We will start at the first story and then progress higher and higher until the satellite has a major failure or we are confident that we have exceeded the situational requirements. We will also include weights inside the satellite to simulate the weight of our components to better simulate the scenario. Based on the results from these tests, we will improve our structural design to better protect its contents. Once we have a design that exceeds situational requirements, we will proceed testing the system as a whole. TUMBLE TEST: In addition to the drop test, we will toss the satellite down several flights of stairs with weights to observe how the structure will hold and protect its contents. This test also shows how well or poorly everything will be secured inside the satellite. If anything breaks loose, the part itself will fail its mission and possibly damage the other contents of the satellite and damage more systems. WHIP TEST: Finally, to ensure that the satellite will remain attached to the balloon rope, we will test to ensure that the pipe used to hold the satellite to the rope will adhere to the satellite even under extreme whiplash conditions. Once a desirable structure is selected, we will put the satellite at the end of a string, attached exactly like it will be to the balloon rope, and test its whip Team Up, Up, and Away Page | 10 B.O.S.S. – Balloon-Operated Seeding System strength. We will take the apparatus to an overhang, hold it over the edge, and violently swing the satellite back and forth to ensure its stability. POWDER RELEASE TEST: We will create our own delivery system to release the powder used to seed the clouds. We expect to modify and tune the system so that it will disperse the powder at the desired altitudes without failure. The goal is to have a system that releases a portion of the satellite’s stored powder at certain altitude intervals. Our initial tests will be run without powder to make sure that the mechanism works. We will then run short tests with the powder in funnel, to make sure that the Servo arm does not get caught and that the powder releases in the proper amounts. Our final test will run for 90 minutes to simulate a long flight time and make sure every part of the system acts as expected and the programming works without fail. ELECTRONICS TESTING: ACCELEROMETER : The accelerometer measures acceleration in three different axes, in order to determine the orientation of the BalloonSat. It is important that the sensor is originally calibrated from a level surface, so that all of the readings are accurate. The accelerometer is programmed to reset to its calibrated level each time it is turned on to ensure that the readings are not skewed. To test that the program works, we will hold the accelerometer flat against the table and then rotate it by 90 degrees every 10 seconds. HEATER: The heater will go through a series of tests: a) Plug the batteries in the system and make sure that the heater can turn on b) Leave the heater in a closed space for 1 hour, to ensure that the heater will not burn out or overheat c) Incorporate the heater in the cooler test (for 1 hour) to ensure that it will still perform, and keep the inside of the box above -10 degrees Celsius during flight. CAMERA: In order to test the functionality of the dual-camera system, we will turn the system on for a full two hours, simulating the duration of the actual flight. For this time, the BalloonSat will be left on a table undisturbed. The digital camera will take pictures every 15 seconds and the GoPro will film for the entire two hours. The cameras will record to their respective SD cards, and we will upload the data to a computer to ensure that the cameras and memory cards operated correctly during the test. HUMIDITY SENSOR: We will first expose the humidity sensor to varying humidity levels by breathing on the sensor and noting if there is a change or not. Next we will test the humidity sensor over a period of days to see if it accurately matches the outside temperature. We will compare this data to various weather websites on the internet. TEMPERATURE SENSOR (DIGITAL AND ANALOG ): We will first test the temperature sensors by holding and then releasing them to see if they detect a change in temperature from the heat provided by our hands. Once we know that they are working, we will work on calibrating them Team Up, Up, and Away Page | 11 B.O.S.S. – Balloon-Operated Seeding System by exposing the sensors to room temperature, refrigerator (0-4 degrees Celsius), and freezer conditions (-5 to -15 degrees Celsius). We will place the sensors next to a thermometer, and graph the readings of each sensors and the thermometer. To ensure that the data is accurate we will wait until the readings stop fluctuating and level out to a constant number. We will then repeat each of these tests a minimum of three times to make sure we are getting consistent readings. After this, we will make the proper changes in the program so that each of the sensors will give accurate readings. The sensors will be tested 3 times each again. Note: The digital sensor will be placed inside the satellite so it only needs to be accurate to -15 degrees Celsius, and may not work as well in the freezer. The analog sensor, however must work in the freezer. ANEMOMETER: The Anemometer will measure wind speed on the outside of the BalloonSat. We will test the anemometer system by setting it in a wind tunnel with a voltmeter connected to the turbine. With the voltmeter data, we will record the speed to determine if it matches up with the speed of the wind. We will test the turbine at 10, 25, and 45 mph, three times each. SYSTEMS TESTING: COOLER TEST: We will use a cooler filled with dry ice to simulate high atmosphere temperatures. We will leave the BalloonSat in the cooler for 1.5 hours with its sensors, servos, and anemometer powered on. At the end of the two hours we will analyze the readings from the SD cards. We expect to see the temperature sensor inside the satellite constant have a constant reading above -10 degrees Celsius, the outside temperature sensor with a steady reading at or starting around 50 degrees Celsius, constant readings from all of the other sensors, and confirmation that the anemometer, and servos were running the whole time. No salt will be added to the system at this stage. COMPLETE SYSTEMS TEST: We will set up the entire system, including both cameras and adding the salt mixture to the funnels. The box will again be placed in the cooler with dry ice, and the test will last for a full 2 hours. At the end we will analyze the readings from the SD cards and make sure all the sensors and cameras preformed correctly. We then will compare the results to the first cooler teat and note any differences. If the differences are too great, we will target the specific sensor and do extra tests on it. For this complete systems test we will also note if the powder was released and if it was released at the right time. We will use the cameras for a visual confirmation, as we will during the flight. With this test we will also confirm that the program is working well and without any bugs. DEMO MISSION TEST: This test will be the same as described in COMPLETE SYSTEMS TEST above, except for a period of 30 minutes as opposed to 2 hours. Team Up, Up, and Away Page | 12 B.O.S.S. – Balloon-Operated Seeding System EXPECTED RESULTS: Team Up, Up, and Away expects to record and recover accurate information from all sensors on the BalloonSat. First, we expect the temperature sensor to detect a decrease in temperature until satellite flies above the ozone layer, where the measured temperature will increase due to solar radiation (Figure 1). During descent, the opposite of this trend will be true and we will see a clear difference the rapidity of the temperature change due to the increased rate of change in altitude during free-fall. We expect to discover with the anemometer that the wind speed will vary during ascent and descent (as show in Figure 2), due to jet streams. We predict that the air pressure will decrease during ascent at a relatively steady rate, and increase upon descent. This trend is due to a decreasing amount of molecules in the surroundings as altitude increases (Figure 3). We expect the humidity to follow a similar trend to temperature for the same reasons. Unlike temperature, however, the humidity will level off before burst. We expect to discover with the accelerometer that there will be an initial upward acceleration at the beginning of the flight, but this will return to zero as the balloon stops accelerating upward. We expect to see small variances in all three axes due to unknown and unpredictable factors such as wind. Upon descent, the G-force in each direction will vary erratically as a result of an unpredictable and turbulent descent. Lastly, we expect the cameras, both the GoPro and the Cannon, to take clear pictures and video throughout the flight. The GoPro will be focused on confirming the release of the sodium chloride powder. Another aspect of expected results is how we predict our mechanisms will function throughout the flight. Presuming the connections are stable and the tests which confirm this are conducted accurately, all mechanisms should properly perform their specific functions flawlessly. Mid-flight confirmation will come from the physical observation of the powder (enhanced by reflective glitter) after its release. Post-flight confirmation will be made through GoPro video of the release. These graphs are used from one of Carolyn Mason’s high school rocket projects. Figure 1 (Temperature vs. Altitude) Figure 2 (Wind Speed vs. Altitude) Figure 3 (Air Pressure vs. Time) Team Up, Up, and Away Page | 13