Berhampore, Murshidabad

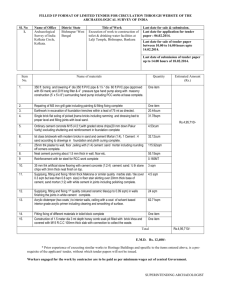

advertisement

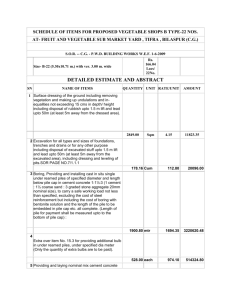

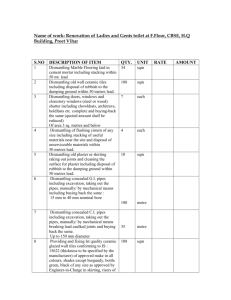

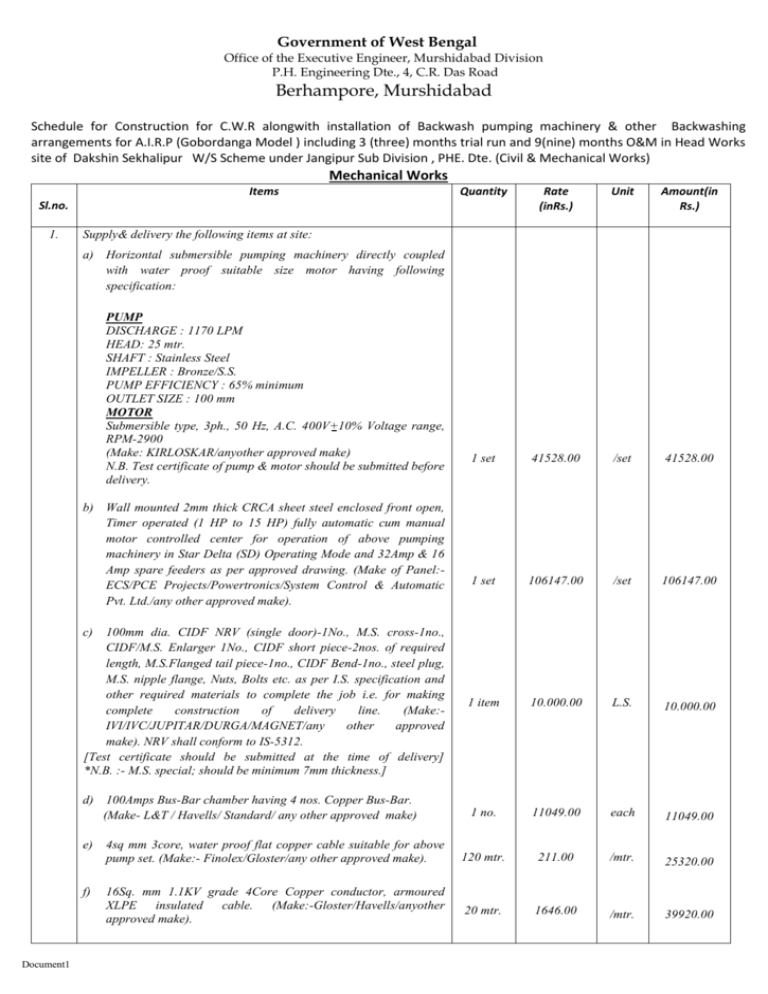

Government of West Bengal Office of the Executive Engineer, Murshidabad Division P.H. Engineering Dte., 4, C.R. Das Road Berhampore, Murshidabad Schedule for Construction for C.W.R alongwith installation of Backwash pumping machinery & other Backwashing arrangements for A.I.R.P (Gobordanga Model ) including 3 (three) months trial run and 9(nine) months O&M in Head Works site of Dakshin Sekhalipur W/S Scheme under Jangipur Sub Division , PHE. Dte. (Civil & Mechanical Works) Mechanical Works Items Quantity Rate (inRs.) Unit Amount(in Rs.) 1 set 41528.00 /set 41528.00 1 set 106147.00 /set 106147.00 100mm dia. CIDF NRV (single door)-1No., M.S. cross-1no., CIDF/M.S. Enlarger 1No., CIDF short piece-2nos. of required length, M.S.Flanged tail piece-1no., CIDF Bend-1no., steel plug, M.S. nipple flange, Nuts, Bolts etc. as per I.S. specification and other required materials to complete the job i.e. for making complete construction of delivery line. (Make:IVI/IVC/JUPITAR/DURGA/MAGNET/any other approved make). NRV shall conform to IS-5312. [Test certificate should be submitted at the time of delivery] *N.B. :- M.S. special; should be minimum 7mm thickness.] 1 item 10.000.00 L.S. 10.000.00 d) 100Amps Bus-Bar chamber having 4 nos. Copper Bus-Bar. (Make- L&T / Havells/ Standard/ any other approved make) 1 no. 11049.00 each 11049.00 120 mtr. 211.00 /mtr. 25320.00 20 mtr. 1646.00 /mtr. 39920.00 Sl.no. 1. Supply& delivery the following items at site: a) Horizontal submersible pumping machinery directly coupled with water proof suitable size motor having following specification: PUMP DISCHARGE : 1170 LPM HEAD: 25 mtr. SHAFT : Stainless Steel IMPELLER : Bronze/S.S. PUMP EFFICIENCY : 65% minimum OUTLET SIZE : 100 mm MOTOR Submersible type, 3ph., 50 Hz, A.C. 400V+10% Voltage range, RPM-2900 (Make: KIRLOSKAR/anyother approved make) N.B. Test certificate of pump & motor should be submitted before delivery. b) Wall mounted 2mm thick CRCA sheet steel enclosed front open, Timer operated (1 HP to 15 HP) fully automatic cum manual motor controlled center for operation of above pumping machinery in Star Delta (SD) Operating Mode and 32Amp & 16 Amp spare feeders as per approved drawing. (Make of Panel:ECS/PCE Projects/Powertronics/System Control & Automatic Pvt. Ltd./any other approved make). c) e) f) Document1 4sq mm 3core, water proof flat copper cable suitable for above pump set. (Make:- Finolex/Gloster/any other approved make). 16Sq. mm 1.1KV grade 4Core Copper conductor, armoured XLPE insulated cable. (Make:-Gloster/Havells/anyother approved make). g) Four pole Isolator having rating of 100 Amp, 240/415V, 50 Hz conforming to IS /IEC: 60947-3.(Make: Havells/Standard/any other approved make) h) Four pole Isolator having rating of 63 Amp, 240/415V, 50 Hz conforming to IS /IEC: 60947-3.(Make: Havells/Standard/any other approved make) i) 1402.00 each 1213.00 /set 300.00 each 278.00 /mtr. 1 set 3900.00 /set 3900.00 1 item 4800.00 L.S. 4800.00 1 item 1500.00 L.S. 1500.00 1 item 1500.00 L.S. 1500.00 120 mtr. 62.00 /mtr. 7440.00 1 set Wooden Block of (1’x1’) and 30mm thick to house the isolators. 2 nos. j) 40 mm dia G.I. Pipe (medium gauge) of approved make. 120 mtr. 2. 3. 4. 5. 6. Document1 Making suitable size concrete pump foundation base at the floor of backwash chamber with supplying cement, sand, stone chips etc. in the portion of (1:2:4) including plastering, neat cement finish etc. This cost includes supply & delivery of 6 nos. SS bolts of suitable length, grouting the bolts at the concrete foundation for holding the pumping machinery, supplying and fitting fixing of suitable nos.of SS nuts, washers all complete upto entire satisfaction of E.I.C. Installation of above supplied pumping-machinery alongwith pipes (supplied departmentally),safety device, specials, flat cable and other accessories as per direction. This cost includes makingrequired arrangement for installation of pumping machinery,inter connection of flat cable with lead cable of motor all complete as per direction. Installation of four pole isolators (as in item no. 1.g) & h)) in supplied wooden block, 100 Amp Bus-Bar chamber (as in item no.1.d), Panel (as in item no. 1.b ) at requiredposition on wall within pump house including supply of required nos. of MS flange, nuts, bolts, gaskets etc. and other fixing materials necessary to complete the job in all respect. This includes the cost of earthing the panel from earth busbar (including its supply &drawing of suitable length 16SWG G.I. wire, finishing the cable ends by crimping method all complete as per direction. Drawing of 16Sq.mm 1.1KV grade 4Core Copper conductor, armoured XLPE insulated cable (as in item no. 1(f)) from installed 100 Amp 3 nos. cut outs to installed 100 Amp isolator, Isolator to Busbar, Busbar to 63 Amp Isolator and Isolator to installed panel through wall of pump house including supply & fitting fixing of required nos. of saddles for holding the cable on walls, sockets, glands and finishing the cable ends by crimping method all complete upto entire satisfaction of E.I.C. This cost includes connecting the existing 100 Amp main switch to the installed busbar by means of 16 Sqmm cable (previously supplied) all complete as per direction. Drawing of 4 Sq.mm 3 Core water proof flat Copper cable(as in item no. 1.e)) partly underground and partly through the boundary wall within the supplied G.I. pipes by means of M.S. saddle all complete. This includes the cost of grouting the boundary wall at suitable positions, supply,delivery of required nos. M.S. Saddlesand fitting fixing of those at the boundary wall , bends etc. required to complete the job in all respect as per direction. 1402.00 1 no. 1213.00 600.00 33360.00 7. 8. Connecting the 4 Sq.mm 3 Core water proof flat Copper cable with the installed panel for backwash operation upto entire satisfaction of E.I.C. This includes the cost of supply, delivery and fitting, fixing of required nos. of cable glands and finishing the cable ends by means of crimping method all complete. (a) Earthing with 50mm diametre G.I. pipe 3.64mm thick x 3Mtr.(10ft.) long and 1 x 4SWG G.I. wire(4Mtr. long) 13mm diametre x 80mm (3inch) long G.I. Bolts, double nuts, washer including S & F 15mm diametre G.I. pipe protection(1Mtr. Long) to be filled with bitumen partly below ground level to an average depth of 3.65Mtr.(12ft.) below the ground level and restoring the surface duly rammed.[This cost includes earth pit and its necessary lid making] 1 item 500.00 L.S. 500.00 2 sets 1350.00 /set 2700.00 2 items 545.00 /item 1090.00 20 mtr. 11.00 /mtr. 220.00 1 item 3250.00 L.S. 3250.00 1 item 1500.00 L.S. 1500.00 15.20 12047.00 %cum 1831.00 1.13 19430.00 %cum 219.56 2.47 7831.00 %cum 193.42 10.20 342.00 Sqm 3488.00 0.75 6085.00 Cum 4563.75 0.90 68359.00 MT 61523.10 (b) Extra for treatment of soil by salt and charcoal coke for pipe electrode. c) Connection the equiments to earth busbar including S & F, G.I. wire 8 SWG on wall/floor with stapplesburried inside as required and making connection to equiments with bolts, nuts, washer cable lugs as required and mending damaged floor goodly. d) 9. The cost of brick work around the earth pits, neat cement finishing, supply & fitting fixing of MS cover plates above the earth pits all complete as per satisfaction of E.I.C. (2 nos. earth pits. Testing, commissioning the whole installation upto entire satisfaction of E.I.C. Civil Works 10 11 12 13 14 Document1 Earth work in excavation of foundation trenches or drains, in all sorts of soil (including mixed soil but excluding laterite or sandstone) including removing, spreading or stacking the spoils within a lead of 75 m. as directed. The item includes necessary trimming the sides of trenches, levelling, dressing and ramming the bottom, bailing out water as required complete. (a) Depth of excavation not exceeding 1.5 m. (b) Depth of excavationfor additional depth beyond 1.50 m and upto 3.0 m but not requiring shoring . Earth work in filling in foundation trenches or plinth with good earth, in layers not exceeding 150 mm including watering and ramming etc. layer by layer complete. a) With earth obtained from excavation of foundation Single Brick flat soling of picked jhama bricks including ramming and dressing bed to proper level and filling joints with local sand. Ordinary cement concrete ( mix 1:2:4 ) with graded stone chips ( 20 mm nominal size ) excluding shuttering and reinforcement if any in ground floor as per relevant IS code . Reinforcement for reinforced concrete work in all sorts of structures including distribution bars, stirrups, binders etc. including supply of rods initial straightening and removal of loose rust (if necessary) cutting to requisite length, hooking and binding to correct shape placing in proper position and binding with 16- gauge black annealed wire at every intersection complete as per direction and drawing. a) For works in foundation basement and upto roof of ground floor upto 4PM i) Tor Steel / Mild Steel 15 16 17 18 19 20 21 22 23 Document1 Hire and labour charges for shuttering with centering and necessary staging upto 4m. using approved stout props with thick hard wood planks of approved thickness with required bracing for concrete slabs, beams, columns, lintels curved or straight including fitting, fixing and striking out after completion of works (upto roof of ground floor) a) 25mm. to 30mm. thick wooden shuttering as per direction of E.I.C Controlled cement concrete with well graded stone chips (20 mm nominal size ) excluding shuttering and reinforcement with complete design of concrete as per IS 456 and relevent special publications submission of job mix formula after preliminary mix design after testing of concrete cubes as per direction of E.I.C . Consumption of cement not less than 300 kg of cement with super plasticiser per cubic meter of controlled concrete but actual consumption will be determined on the basic of preliminary test and job mix formula . In G.F M 25 Grade a) Pakur / Chandil Variety. Plaster (to wall, floor, ceiling etc.) with sand and cement mortar including rounding off or chamfering corners as directed and racking out joints or roughening of concrete surface including throating, nosing and drip course where necessary (ground floor) (a) 15mm. thick plaster. (4:1) (b) 10mm. thick plaster(4:1) Neat cement punning about 1.5mm thick in wall, dado, window, ceiling, floor, drain etc. Artificial stone in floor, dado, staircase etc. with cement concrete (4:2:1) with stone chips, laid in panels as directed with topping made with ordinary/white cement (as necessary) and marble dust in proportion (2:1) including smooth finishing and rending off corners and including application if cement slurry before flooring works, using cement @ 1.75 kg. per sq. mtr. all complete including all materials and labour. (a) 40 mm thick. Priming one coat on steel or timber, surface with synthetic enamel painter as approved quality including smoothening surfaces by sand papering etc. (b) On Plaster Surface Painting with best quality synthetic enamel paint of approved make and brand including smoothening surface by sand papering etc. including using of approved putty etc. On timber or plastered surface (with other than hi gloss of approved quality).Two Coat (with any shed, except white). Excavation trench of adequate width as per drawing for laying CISS/CIDF/CI/DI/TYTON /G.I. Pipes of all classes, sluice valves and special in all sorts of soil including mixed with boulder, road sub grade and its flank, preparing the bottom surface for continuous bedding of Pipe Line or laying pipes, special and valves in proper alignment with bailing out porter if required including carriage of pipes, valves specials etc. from local store within 8 Km. cutting pipes where necessary, keeping a clean cover of at least into Between G. I. to Top of pipes and back filling the trenches with (using excavated earth ) in layers to original condition as per specification and direction of the E.I.C. a) 100 mm. dia Making flange joint to CI/GI/UPVC pipes, specials and valves where necessary with supply of necessary rubber insertion of 3 mm. thickness, bolts, nuts, washers etc. of approved quality and type and painting complete as per specification and drawing. a) 100 mm. dia 60.20 354.00 Sqm 21310.80 6.90 7336.00 Cum 50618.40 30.15 10.20 170.00 135.00 Sqm Sqm 5125.50 1377.00 32.16 38.00 Sqm 1222.08 30.00 360.00 Sqm 10800.00 36.50 41.00 Sqm 1496.50 36.50 80.00 Sqm 2920.00 16.50 44.00 Mtr 726.00 6.00 150.00 Each 900.00 24 Construction of masonry valve chamber/washout chamber as per departmental approved drawing No. M.C. TY/SV/02/08 with brick work in cement mortar (1:6) with weep hole over a layer of (1:4:8) cement concrete 100 mm. thick with stone metal on polythene sheet including earth work in excavation covered with 100 mm. thick precast RCC (1:1:5:3) M-20 slab with necessary side shuttering and reinforcement work and other materials as per departmental drawing complete with supply 150 mm. × 150 mm. × C. I. Surface Box embedded into the precast slab including fitting, fixing over the chamber and overhauling the valves (if necessary) all compete including cost of all labour and materials (only valves with tail pieces will be supplied from local departmental store) Supplying, fitting and fixing G.I pipes of TATA make with all necessary accessories, specials viz. socket, bend, tee, union, cross, elbo, nipple, longscrew, reducing socket, reducing tee, short piece etc fitted with holder bats clams, including cutting pipes, making threads, fitting fixing etc.complete in all respect including cost of all necessary fittings as required, joining materials and two coats of painting with approved point in any position above ground .( payment will be made on the centre line measurements of total pipe line including all specials. no seperate payment will be made for accessories, specials. payment for painting will be made seperately) 50 mm dia medium quality 25 1 9784.00 Each 9784.00 1.50 624.00 Mtr 936.00 Total (Rs.) 477975.00 (Rupees four lakh seventy seven thousand nine hundred seventy five) only Executive Engineer Murshidabad Division, P.H. Engineering Dte. Document1