155-92-1-SP

advertisement

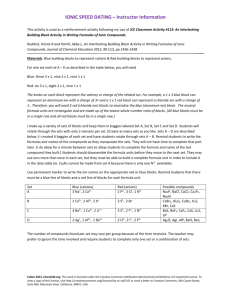

Printable, Non-aqueous Emulsion-templated Polymer Separators for Li Ion Batteries Natasha Shirshova1, Stephen Johns1, Alexander Bismarck2, Jérémie Salomon3, Hélène Rouault3, Joachim H. G. Steinke1 1. Department of Chemistry, Imperial College London, London SW7 2AZ, UK. e-mail: j.steinke@imperial.ac.uk 2. Department of Chemical Engineering and Chemical Technology, Imperial College London, London SW7 2AZ, UK. 3. Commissariat à l'énergie atomique (CEA) Grenoble, DRT/DTEN/SCSE/LSEM, 17 rue des Martyrs, F38054 Grenoble, France. Introduction Lithium ion batteries are one of the key device components for portable energy storage. Mayor interests in lithium ion batteries are concerned with “greener” transport options such as hybrid cars and are ubiquitous in portable electronic devices and equipment. In conjunction with solar cells energy generation and storage can be performed locally leading to new ways of delivering energy for applications requiring mobility and power. With the intense interest in energy storage, research into lithium ion batteries addresses essentially all aspects of performance improvements: (i) New materials for higher charge densities which are at the same time environmentally more benign, (ii) electrode materials with better cyclability, (iii) greener electrolytes such as those based on ionic liquids and (iv) separators with higher ion flux for faster charging and discharging kinetics. Overarching as a theme to all those activities is the production of Li ion batteries is the need for low energy processing routes combined with simpler production techniques and more environmentally benign deposition routes. In this contribution we will present our efforts in integrating more desirable processes for Li ion battery production with the development of new materials, which can be processed more easily, are environmentally friendly, but do not sacrifice performance. Results and Discussion The focus of our research is to develop a separator membrane filled with environmentally low impact electrolytes such as ionic liquids, which can be printed directly and be used in a rollto-roll process, leading to significant environmental and cost advantages in the production of thin film batteries. To achieve high energy and power densities, the separator has to be thin and highly porous, to be able to absorb the electrolyte, while still remaining mechanically strong1. Separators can be divided into three groups: macroporous polymers, non-woven fabric mats and inorganic composite membranes. Typically, the manufacturing of separators is a multistep process. Our approach to a printable separator is based on the formation of a highly porous polymer network which can be generated in a single step. As pore- and network forming strategy we have chosen emulsion templating to produce highly porous polymer matrices.2,3 Non aqueous high internal phase emulsions were prepared (Figure 1) by addition of the dispersed phase (consisting of an ionic liquid doped with Li salt) into the external phase (a combination of thermal or UV radical polymerisation initiators, monomer, crosslinker and a surfactant). PolyHIPE + electrolyte Electrodes Dispersed phase (org solvents, IL) Monomer + Xlinker + surfactant + printing UV, T (oC) Figure 1. Schematic representation of in situ synthesis of a porous separator membrane prefilled with liquid electrolyte for printable thin-film Li ion batteries. The emulsion was then cast as film and polymerised using thermal or photochemical radical initiation. By varying the monomer to crosslinker ratio, the surfactant concentration and the external phase volume, we were able to control morphology, ionic conductivity and mechanical properties of the resulting separator materials. Stable HIPE conditions were identified and both thermal and photo-polymerisation led to highly porous thin films pre-filled with polymer electrolyte (an example of the pore morphology of such a polyHIPE is shown in Figure 2). Without the need of filling the separator membrane in a post-polymerisation step with electrolyte, we obtained conductivities ranging between 1-10 mS/cm. Details on the properties of the synthesised HIPEs and polyHIPEs as well as the outcome of printing trial of these separator/electrolyte inks as part of a thin film battery production route will be presented at the meeting. Figure 2. SEM image of a polyHIPE morphology representative for emulsion template Li ion separator membranes with ionic liquid-based electrolyte as dispersed phase. Conclusions In conclusion, appropriate conditions and monomer/crosslinker pairs have been identified, which allowed us to produce a (highly porous) polyHIPE thin films. These thin films do not requiring post-filling with electrolyte as is common practice, but are already prefilled with ionic liquid electrolyte. Our approach will simplify the way in which thin film lithium ion batteries can be produced while we are were able to achieve conductivities very similar to that of pure liquid electrolyte. We believe this demonstrates an important advance in the ability to realise more environmentally friendly and more cost effective thin film batteries via multi-layer printing as the emulsion-templated separator material is suitable as an ink for high throughput roll-to-roll production processes. Acknowledgements This work was funded as part of the GREENBAT project under the seventh framework programme (FP 7) of the European Commission (FP7-ICT-2007-2). References 1. S. S. Zhang, J. Power Sources 2007, 164, 351-364. 2. A. Barbetta; R.J. Carnachan; K.H. Smith; C. Zao; N.R. Cameron; R. Kataku; M. Hayman; S.A. Przyboski; M. Swan, Macromol. Symp. 2005, 226, 203-211. 3. A. Menner; R. Powell; A. Bismarck, Macromolecules 2006, 39, 2034-2035