Supplemental Materials

advertisement

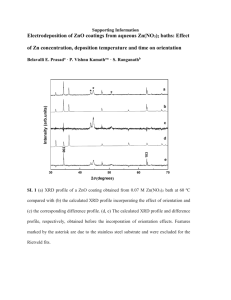

Supplemental Materials Detailed experimental procedure The initial hot-rolled 304L billet was austenitized at 1150C for 2 hours. The rods for ECAP processing had a dimension of 8 45 mm and were cut from the annealed billet. The ECAP procedure was performed using a split die made from a tool steel with two channels intersecting at an inner angle of 90° (Φ and an outer angle of 30° (Ψ). Both the inlet and outlet channels had the same diameter of 8 mm. The rods were coated with MoS2 lubricant and were pressed for 6 passes at RT. In order to avoid the instability of punch, the pressing speed was selected to be slow (~9 mm/min). Route Bc was adopted, that is, the sample was rotated round its longitudinal axis by 90° clockwise before each pass. The equivalent von Mises strain for a single pass is ~1. After ECAP deformation, the deformed rods were subjected to annealing treatment at 625 oC for 1 hour. The dog-bone shaped tensile samples were cut from the annealed rods, with gauge dimension of 1 mm × 2 mm × 8 mm. Uniaxial tensile tests were carried out on an electromechanical materials testing machine at an initial strain rate of 5×10-4 s-1 at RT. The microstructures of 304L samples before and after tension were characterized by means of optical microscopy (OM), electron backscattered diffraction (EBSD), transmission electron microscopy (TEM) and X-ray diffraction (XRD). For OM, EBSD and XRD experiments, the specimens were ground and electro-chemically polished in a solution of 10 g oxalic acid and 100 ml water at a voltage of 10 V. EBSD examinations were performed on a JSM-7001F type field emission scanning electron microscope equipped with a fully automatic EBSD analysis system. An area of 10 μm × 10 μm was scanned with a step size of 50 nm. More than 90% of the raw data can be indexed by the TSL OIM Data Collection 5 Software. TEM observations were performed on JEM-2000FX II microscope and FEI 20 high resolution microscope, both of which were operated at 200 kV. The TEM samples were sliced from annealed rods and tensile strained specimens, ground to ~70 m thick and then thinned by the twin-jet polishing method in a solution of 10% perchloric acid and 90% ethanol at -15 oC and at 18~22 V. XRD experiments were carried out to determine the phase constitution by using a Rigaku D/max-2400 X-ray diffractometer (12 kW) with Cu K radiation. In XRD experiments, only the gauge part of tensile sample was scanned. Figure S1. Optical images showing the initial and deformed UFG 304L sample at different tensile strains. The Lüders bands can be seen on the sample surface. Figure S2. XRD profiles for the UFG sample at different tensile strains. It can be seen that there is no martensite diffraction peaks, which indicates that no strain-induced martensite transformation occurred during tensile deformation.